In today’s fast-paced manufacturing and logistics environment, packaging efficiency has become a strategic priority. Businesses are under pressure to reduce costs, improve productivity, and maintain high-quality standards. Manual packaging processes—while initially appealing due to lower setup costs—often lead to operational inefficiencies, labor bottlenecks, and inconsistent outcomes.

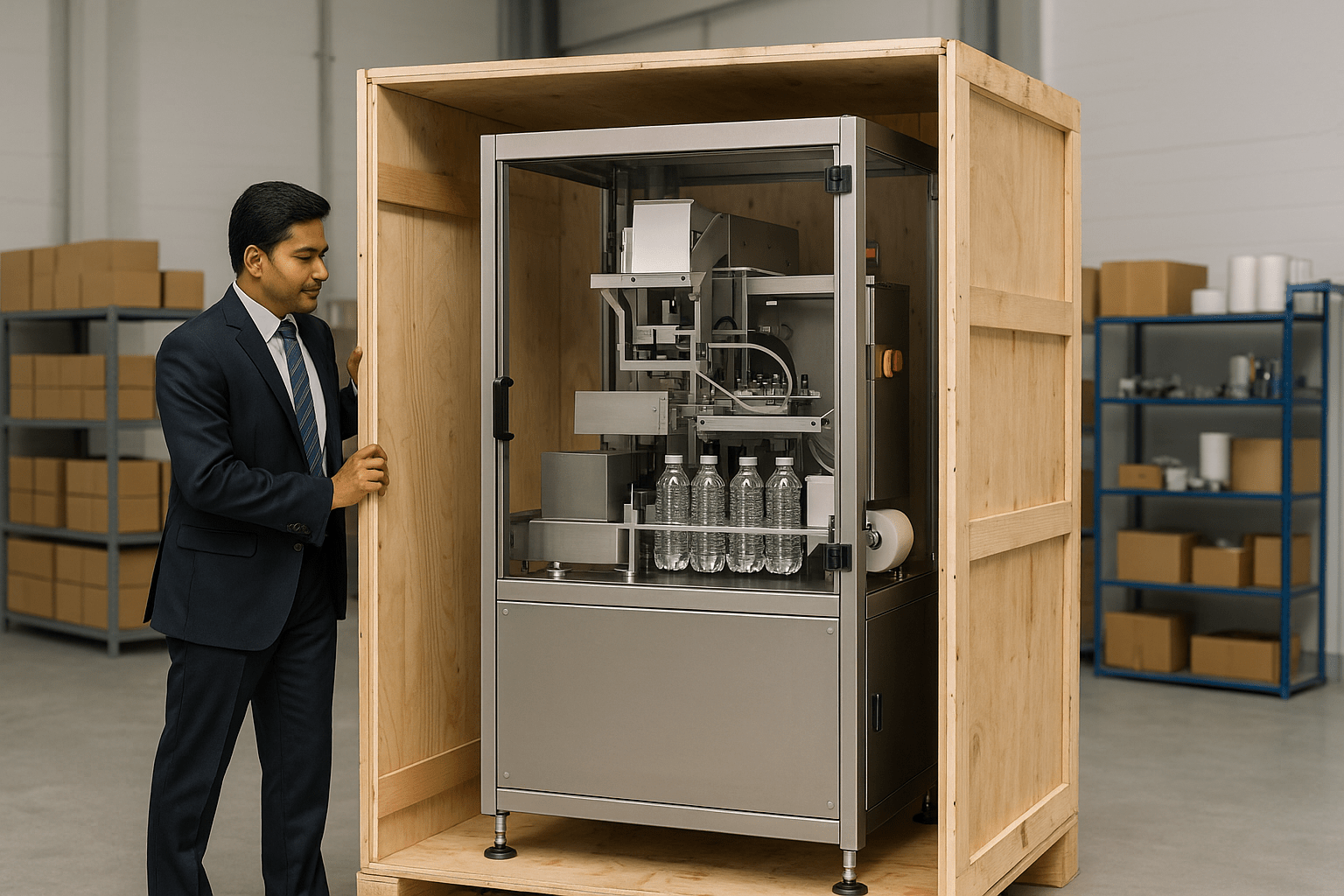

Imagine a single machine capable of inserting product leaflets, collecting bottles, and wrapping them—all within a streamlined process. This revolutionary, all-in-one system not only addresses longstanding inefficiencies but also propels businesses toward smarter, more sustainable manufacturing. Let’s explore how this integrated system saves time, cuts labor costs, and elevates your packaging line’s performance.

Before highlighting the advantages of the integrated solution, it’s important to understand the pitfalls of conventional, segmented packaging setups:

1. Labor-Intensive Operations

2. Excessive Use of Floor Space

3. Downtime & Bottlenecks

4. Inconsistent Product Output

5. Complex Maintenance Requirements

| Aspect | Traditional Setup | All-in-One Machine |

|---|---|---|

| Labor | 3+ operators | 1 operator |

| Time | Slower due to manual steps | Faster automated process |

| Errors | Higher due to manual handling | Significantly reduced |

| Maintenance | Multiple points of failure | Centralized, easier maintenance |

| Feature | Description |

|---|---|

| Control System | PLC with HMI touch screen |

| Leaflet Insertion Accuracy | ±0.5 mm, vision-based alignment |

| Bottle Types Supported | PET, HDPE, Glass (customizable molds) |

| Wrapping Types Supported | Shrink, Stretch, or Bundling |

| Speed | Up to 60 units per minute (configurable) |

| Safety Features | Emergency stop, interlock sensors, overload alerts |

| Machine Footprint | Compact design (customizable) |

| Material Compatibility | Film, PVC, PE, POF, LDPE |

Note: Specifications vary by model. At AmarPack Machines Pvt Ltd, we offer customized solutions based on your product size and throughput requirements.

While the initial investment in an all-in-one system might appear significant, it’s crucial to view it as a strategic investment with a rapid return. The cumulative savings in labor, reduced waste, increased throughput, and optimized floor space quickly offset the upfront cost. Furthermore, the enhanced consistency and reliability contribute to a stronger brand reputation and customer loyalty.

When evaluating such a system, consider factors like:

The “One Machine, Triple Function” system for leaflet inserting, bottle collecting, and wrapping represents a significant leap forward in packaging automation. It addresses the core challenges of labor intensity and inefficiency inherent in traditional methods by offering a streamlined, high-performance solution. For businesses looking to optimize their operations, cut costs, boost productivity, and maintain consistent quality in their bottled product lines, investing in such an all-in-one system is not just an option, but a strategic imperative. The future of efficient and professional packaging is undoubtedly integrated, and this triple-function machine is leading the way.

When it comes to packaging automation, experience matters. AmarPack Machines Pvt Ltd is a trusted name in India and internationally for high-performance, durable, and customizable packaging solutions.

What Sets Us Apart:

Over 25+ years of manufacturing expertise

International quality standards (exported to 30+ countries)

Tailor-made solutions for industry-specific needs

24/7 service support and trained technicians

Prestigious clientele including Colgate, Cipla, Flipkart, Marico, L&T, and more

It ensures each product is packaged with the required documentation, improving compliance and patient safety.

Yes, it is designed to be compatible with a wide range of bottle shapes and sizes through quick-change parts.

Depending on configuration, the machine can process XX to XX bottles per minute.

Not at all. It features low-maintenance components and offers easy access for routine servicing.

Yes, the machine complies with international packaging norms and is CE-certified.

Founded in 1998 in Mumbai, India, AmarPack Machines Pvt. Ltd. is one of India’s leading manufacturers and exporters of premium packaging machines. Read More

GST No. 27AAZCA2345J1Z6

Get a quick quote from our experts. Fast response guaranteed!