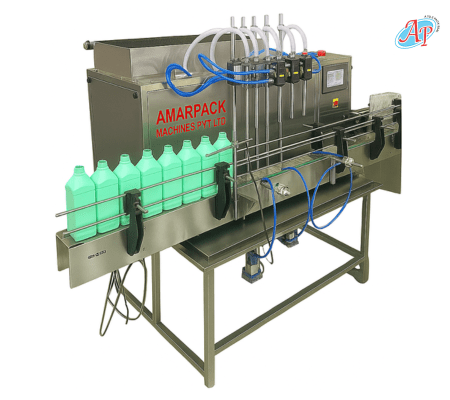

The Six Head Liquid Filling Machine from AmarPack Machines Pvt Ltd is a robust, high-output system designed for automatic filling of pharmaceutical and nutraceutical liquids. With six precision-engineered nozzles working in perfect synchronization, it ensures uniform dosing, zero-drip filling, and a production speed of up to 100 bottles per minute.

Ideal for products like syrups, suspensions, oral liquids, tonics, and herbal formulations, this machine integrates seamlessly into a complete automated packaging line — including bottle feeding, capping, induction sealing, and labeling.

Designed for GMP-compliant operations, this machine features SS 316L contact parts and a SS 304 frame, making it ideal for cleanroom installations in pharmaceutical manufacturing. The PLC-controlled HMI interface allows easy operation and recipe changes, ensuring high productivity with minimal human touch.

Whether you’re filling glass, PET, or HDPE bottles, the machine adjusts effortlessly to different sizes, thanks to interchangeable tooling and optional diving/drip-free nozzles.

| Specification | Value |

|---|---|

| Model | AmarPack SLF-06 |

| No. of Filling Heads | 6 |

| Filling System | Volumetric Piston / Servo Driven |

| Filling Range | 10 ml to 1000 ml (interchangeable parts) |

| Filling Accuracy | ±1% |

| Output Speed | Up to 90–100 bottles/min (depending on size) |

| Contact Parts | SS 316L |

| Frame Material | SS 304 (GMP Grade) |

| Power Supply | 230V / 50Hz / Single or Three Phase |

| Control System | PLC + HMI with Touchscreen |

| Container Types | PET, HDPE, Glass Bottles |

| Optional Features | Diving Nozzles, Drip-Free Nozzles, Conveyor |

Six Synchronized Filling Heads:

Increase throughput while maintaining ±1% dosing accuracy.

Flexible Dosing System:

Choose between volumetric piston or servo-driven systems depending on your formulation.

Smart Control Panel:

Equipped with PLC + touchscreen HMI for real-time monitoring and speed adjustment.

Modular & Customizable:

Optional features like drip-free nozzles, diving heads, and stainless steel conveyors to suit your operation.

Bottle Versatility:

Handles PET, HDPE, and glass bottles of various shapes and sizes.

Depending on fill volume and product type, it can fill up to 90–100 bottles per minute.

Yes. It features SS 316L contact parts and GMP-compliant design for sterile and clean environments.

Yes. With minor adjustments, it can fill 10 ml to 1000 ml bottles, making it highly flexible.

It’s ideal for free-flowing to medium-viscous liquids such as syrups, suspensions, tonics, and more.

Yes. AmarPack Machines Pvt Ltd offers installation and support in Hyderabad, Mumbai, Baddi, Ahmedabad, Pune, and other pharma zones.

Yes, we offer both 230V single-phase and three-phase models to suit your setup.

Very easy — the machine features quick-change tooling and pre-programmed volume settings.

Founded in 1998 in Mumbai, India, AmarPack Machines Pvt. Ltd. is one of India’s leading manufacturers and exporters of premium packaging machines. Read More

GST No. 27AAZCA2345J1Z6

Get a quick quote from our experts. Fast response guaranteed!