If you’re a business owner exploring efficient and affordable packaging solutions, the Semi-Automatic Shrink Chamber Machine might already be on your radar. But how do you know if it’s the right investment for your packaging line? This comprehensive, keyword-rich buyer’s guide answers common questions and concerns from the point of view of a buyer, helping you make an informed decision.

A Semi-Automatic Shrink Chamber Machine is a packaging system that integrates both sealing and shrinking into one compact unit. It utilizes a heating element to shrink plastic film around the product, ensuring a tight, tamper-proof wrap. The machine is designed for manual placement of products into the film sleeve, after which the chamber hood is pulled down. The machine then performs both sealing and shrinking, offering an efficient, semi-automated solution for low to medium-volume packaging operations.

These machines are especially suitable for operations that don’t require fully automated systems but still need efficiency, professionalism, and safety in their packaging. Common materials used with this system include PVC shrink film, POF shrink film, and polyolefin shrink wrap, each chosen based on product type and required presentation.

Ideal Business Types:

Enhanced Product Presentation – Clean, professional, tamper-evident packaging

Increased Shelf Life – Protects products from dust, moisture, and handling

Improved Operational Efficiency – Sealing and shrinking in one step

Compact Footprint – Easy to fit in small production units or workshops

Low Operational Cost – Suitable for businesses with tight budgets

| Feature | Semi-Automatic Shrink Chamber | Fully Automatic Shrink Machine |

| Cost | Affordable for SMEs | Higher upfront investment |

| Operator Involvement | Requires manual loading | No operator needed after setup |

| Production Rate | Medium (300–600/hr) | High (up to 1500/hr) |

| Maintenance | Basic upkeep | Requires skilled technicians |

| Best For | Growing businesses | High-output manufacturing lines |

Fully automatic systems are ideal for businesses processing tens of thousands of units daily. For everyone else, the semi-automatic option strikes a balance between efficiency and affordability.

Choose Shrink Chamber Machine if:

Choose Shrink Tunnel Machine if:

FMCG Industry:

Shrink Tunnel Machine is ideal for bulk packaging of bottles, jars, cartons

Shrink Chamber Machine is perfect for individual or combo packs in gift boxes

Food & Beverage Industry:

Use Shrink Tunnels for water bottle packaging, biscuit trays, or multi-pack snacks

Use Shrink Chambers for artisanal food products, chocolates, and sweets

Pharmaceutical & Cosmetics:

Shrink Tunnel Machines ensure tamper-proof packaging of medicine boxes and tubes

Shrink Chambers are used for cosmetic kits, small boxes, and gift packs

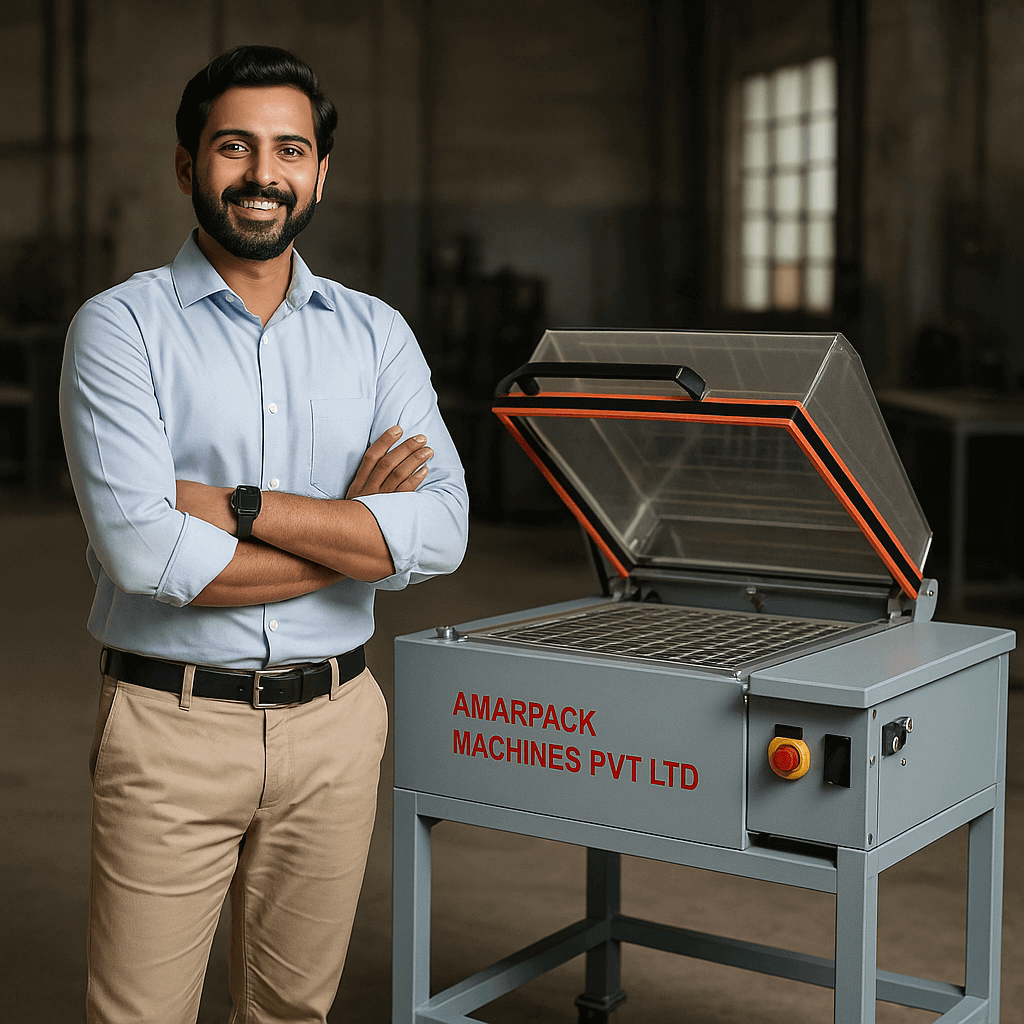

AmarPack Machines Pvt Ltd is a leading manufacturer and exporter of shrink packaging machines in India. Whether you’re looking for a compact shrink chamber or a high-efficiency shrink tunnel machine, we provide tailored solutions for your industry needs.

Our Strengths:

There’s no one-size-fits-all answer when it comes to shrink packaging. Your decision should be based on volume, budget, industry, and product type.

For low-volume and versatile packaging: go with a Shrink Chamber Machine

For industrial, high-speed packaging: invest in a Shrink Tunnel Machine

Both machines are valuable assets to any business involved in packaging and offer excellent ROI when selected based on the right application.

PVC and Polyolefin (POF) films are most commonly used with shrink chamber machines.

Typically no. A shrink tunnel works best when paired with a L-sealer or web sealer for sealing the film before it enters the tunnel.

A shrink chamber machine is more affordable and suitable for small-scale needs.

Yes. Shrink tunnels are excellent for multi-pack or bundle packaging.

It typically takes around 5–10 seconds per unit, depending on product size and film type.

Founded in 1998 in Mumbai, India, AmarPack Machines Pvt. Ltd. is one of India’s leading manufacturers and exporters of premium packaging machines. Read More

GST No. 27AAZCA2345J1Z6

Get a quick quote from our experts. Fast response guaranteed!