📩Get Expert Advice or a Demo Today!

In today’s fast-paced manufacturing and export-driven industries, product shelf life, packaging hygiene, and moisture control are not just value-adds—they’re competitive necessities. Whether you’re in food processing, pharmaceuticals, electronics, or chemical manufacturing, choosing the right vacuum packaging solution directly impacts product quality, operational efficiency, and customer satisfaction.

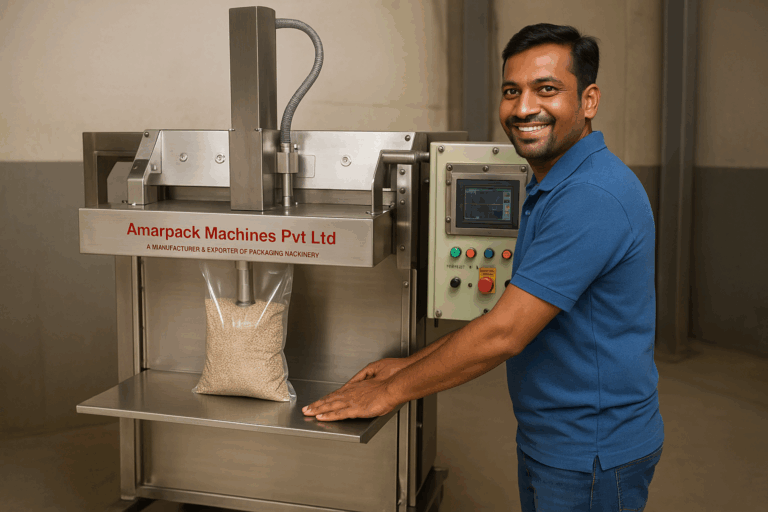

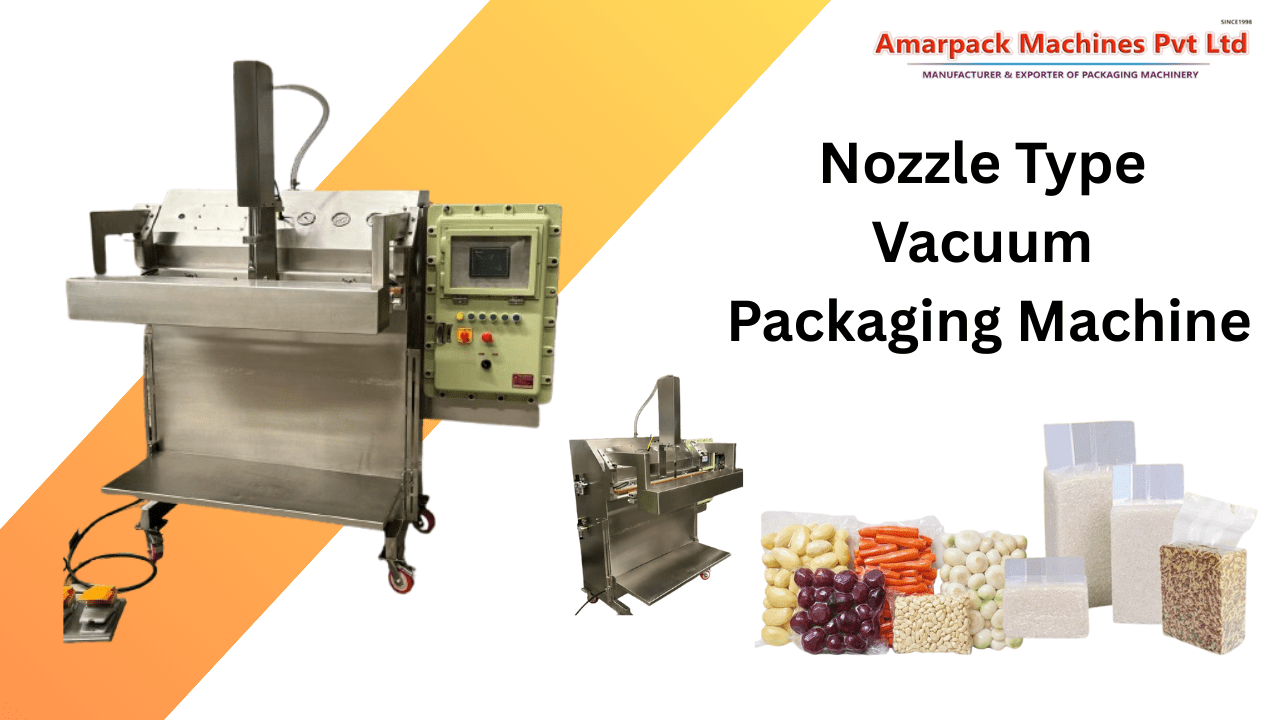

Among the most popular options, the Nozzle Type Vacuum Packaging Machine has become a top choice for businesses requiring flexible, efficient, and affordable vacuum sealing solutions.

But is it the best fit for your business model?

This comprehensive guide will help you evaluate its benefits, working process, industry use-cases, pros vs cons, and how it compares to other vacuum sealing technologies.

A Nozzle Type Vacuum Packaging Machine uses a retractable stainless steel nozzle to extract air from the packaging bag externally. After vacuuming, the bag is tightly sealed using heat, protecting the contents from moisture, air, and contamination.

Unlike chamber-type machines that enclose the bag entirely, nozzle types work outside the chamber, giving you greater flexibility in bag size and material.

1. Versatile Packaging for Different Product Sizes

From small sachets to large industrial pouches, nozzle-type machines handle a wide range of bag sizes. No need to worry about chamber limitations.

2. Compatible with Liquids and Semi-Liquids

Thanks to precision vacuum control, this machine is ideal for sealing products like pickles, sauces, marinated meats, and chemicals—where chamber machines often struggle.

3. Compact, Space-Saving Design

Unlike large chamber units, nozzle vacuum machines are table-top or mobile, making them perfect for space-conscious production floors.

4. Lower Operational Costs

Because they don’t require a sealed chamber or heavy-duty infrastructure, maintenance and operational costs are lower—ideal for growing businesses.

5. Improved Shelf Life and Product Integrity

Vacuum-sealed bags extend shelf life by preventing oxidation, mold growth, and spoilage, giving your brand a higher standard of quality.

6. Compliance with Export Standards

Nozzle vacuum packaging ensures moisture-free and hygienic sealing, making it compliant with international food, pharma, and electronics packaging regulations.

| Industry | Use Case |

|---|---|

| Food & Beverage | Meat, spices, grains, pickles, frozen items |

| Pharma | Bulk drugs, powders, medical kits |

| Electronics | Moisture-sensitive components and circuit boards |

| Agriculture | Seeds, fertilizers, organic produce |

| Chemical | Liquids, semi-liquids, pastes, and solvents |

| Feature | Nozzle Type Machine | Chamber Type Machine |

|---|---|---|

| Bag Size Flexibility | High – works with any size | Limited to chamber dimensions |

| Suitable for Liquids | Yes (with controlled nozzle flow) | Limited or risky without upgrades |

| Speed of Operation | Medium (ideal for semi-auto setups) | Fast (bulk processing) |

| Initial Cost | Lower | Higher |

| Maintenance Complexity | Low | Moderate |

| Ideal For | Diverse, non-uniform product lines | Uniform, high-volume production |

Before making your investment, ensure the machine offers the following features:

✔️ Adjustable vacuum and sealing time

✔️ High suction capacity (250–500 L/min)

✔️ Food-grade stainless steel construction (SS304/SS316)

✔️ Digital control panel with auto-cut safety

✔️ Oil-lubricated heavy-duty vacuum pump

✔️ Emergency stop and auto-retract nozzle function

✔️ Customizable to integrate with conveyors or automation lines

Pro Tip: Always ask for a demo with your product type to ensure compatibility.

If you need a packaging solution that’s:

Flexible across product types and sizes

Capable of sealing liquids and semi-liquids

Compact, cost-efficient, and future-ready

Ideal for export, retail, or B2B supply

… then a Nozzle Type Vacuum Packaging Machine is one of the smartest investments you can make in 2025.

It balances performance, price, and practicality—making it a favorite across SMEs and enterprise packaging lines alike.

Yes. Nozzle machines are compatible with most bag styles, including gusseted and zip-lock vacuum bags.

Yes. These machines can run continuously with minimal breaks, especially if equipped with a durable vacuum pump.

Many advanced models include nitrogen flushing for oxygen-sensitive products.

Machines built with SS304 or SS316 materials are HACCP and FDA compliant.

Yes. Some models come with modular designs that support automation and PLC control upgrades.

AmarPack Machines Pvt. Ltd., founded in 1998, is a leading manufacturer and exporter of packaging machines in India. With over 25 years of experience, we specialize in shrink wrapping machines, vacuum packaging machines, band sealers, and automatic liquid filling machines, delivering reliable packaging solutions to diverse industries in India and international markets

Get a quick quote from our experts. Fast response guaranteed!