In today’s fast-paced manufacturing environment, maximizing efficiency, minimizing errors, and maintaining high standards of product quality are top priorities for business owners. One of the best ways to achieve this is by integrating a conveyor system with your batch coding machine. While a batch coding machine is essential for marking products with critical information like expiration dates, lot numbers, and barcodes, a conveyor system brings added automation that transforms how you approach production. In this blog, we’ll dive deep into how this integration can revolutionize your production line, reduce costs, and improve both speed and accuracy.

Let’s explore the top benefits of adding a conveyor to your batch coding machine, especially from the perspective of manufacturers and business owners looking to stay ahead in the competitive market.

One of the primary benefits of adding a conveyor to your batch coding machine is the boost in productivity. Automation in production lines allows products to flow continuously from one station to the next, reducing time-consuming manual interventions. Here’s how it benefits your workflow:

Seamless Transport: With a conveyor system, products are automatically delivered to the batch coding machine without human intervention, ensuring that your coding process never stops.

Faster Throughput: As products move through the system without delay, batch coding machines can operate at their optimal speed, resulting in faster output and reduced processing time.

This continuous flow not only maximizes production capacity but also supports high-volume production runs, essential for businesses aiming to meet increasing demand without compromising on product quality.

Manual labor in product coding often leads to inconsistencies, errors, or misplaced labels, which can be costly. By integrating a conveyor with your batch coding machine, you can significantly reduce these risks:

Precise Alignment: The conveyor system ensures products are consistently aligned for precise coding, eliminating misalignment errors that can occur in manual processes.

Automated Handling: With automated product handling, the risk of human mistakes like wrong placements or overlooked product markings is minimized, resulting in consistent quality across all batches.

In regulated industries like pharmaceuticals, food packaging, and cosmetics, where accuracy is non-negotiable, this reduction in human error helps businesses maintain high standards and comply with strict regulatory requirements.

For businesses in sectors where traceability is paramount, such as pharmaceuticals, food & beverage, and cosmetics, having a reliable system to track products is crucial. A batch coding machine with a conveyor system significantly improves product traceability:

Real-Time Coding: As products pass through the conveyor, they are automatically coded with batch numbers, expiration dates, and other essential details, providing an up-to-date record for each product.

Seamless Integration: The integration ensures that each product is marked consistently, creating a traceable path from the start of the production line to the end. This audit trail is vital for compliance with FDA guidelines, ISO standards, and GMP regulations.

With automated traceability, your business can easily meet compliance standards and maintain an efficient product recall process in case of any safety issues, safeguarding both your reputation and bottom line.

As your business expands, your production line must be able to scale up to meet new demands. A batch coding machine with a conveyor offers significant flexibility and scalability to accommodate future growth:

Easily Adaptable: Conveyor systems are customizable and can handle different product sizes, shapes, and speeds, making it simple to scale your operation as needed.

Future-Proof Solution: As you increase your production volume, you can add more conveyors or batch coding machines to keep up with demand without major redesigns or facility overhauls.

This scalability ensures that your production line remains efficient and cost-effective as your business grows, allowing you to serve larger orders without disrupting your workflow.

Efficient space utilization is a critical concern for manufacturers. Integrating a conveyor with your batch coding machine can help optimize floor space while maintaining a streamlined production line:

Compact and Efficient Design: Conveyor systems are designed to occupy minimal floor space, making them ideal for facilities where space is limited. By moving products automatically, you free up space for other critical equipment or processes.

Streamlined Workflow: Products flow through the system in an organized manner, reducing clutter and eliminating the need for manual staging or bottlenecks, ultimately improving the overall layout of your production area.

Maximizing space usage allows businesses to optimize workflows, improve safety, and boost operational efficiency without the need for costly expansions.

The integration of a conveyor system with your batch coding machine ensures high reliability and consistent product quality:

Continuous Operation: The conveyor system is built to operate continuously, with minimal downtime and maintenance. This reliability is key for businesses that need to maintain a steady output.

Uniform Coding Across All Batches: Automation guarantees that every product receives the same level of attention, ensuring that all items are marked consistently, enhancing product consistency.

This reliable, high-quality performance is critical for industries that require stringent quality assurance and consistency across large production runs.

Integrating a conveyor system with your batch coding machine offers a wealth of advantages that can significantly enhance your production capabilities. From improving productivity and reducing errors to ensuring compliance and traceability, this combination is a game-changer for businesses looking to stay competitive in an ever-evolving market.

Whether you’re in the food industry, pharmaceutical sector, or any other regulated industry, this powerful automation duo ensures efficiency, accuracy, and scalability, enabling your business to handle high-volume production with ease and consistency.

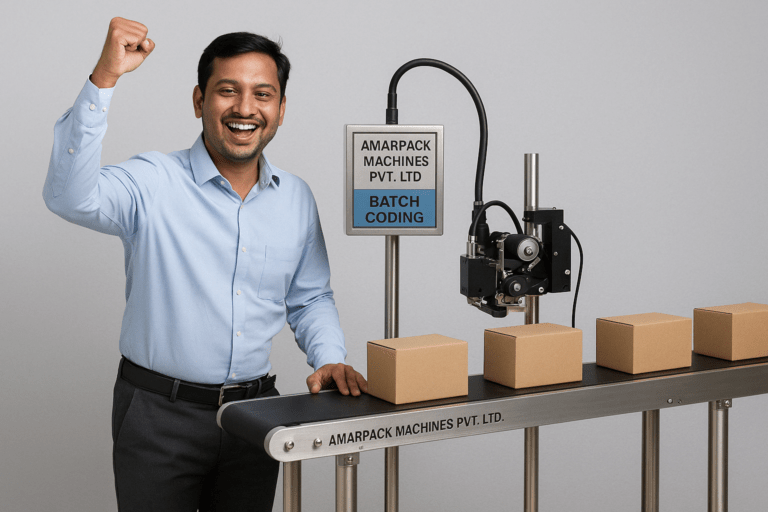

At AmarPack Machines Pvt Ltd, we offer a range of batch coding machines with conveyor systems designed to meet the needs of businesses across various industries. Get in touch with us today to learn how our solutions can help you optimize your production line and boost efficiency.

AmarPack Machines Pvt. Ltd., founded in 1998, is a leading manufacturer and exporter of packaging machines in India. With over 25 years of experience, we specialize in shrink wrapping machines, vacuum packaging machines, band sealers, and automatic liquid filling machines, delivering reliable packaging solutions to diverse industries in India and international markets

Get a quick quote from our experts. Fast response guaranteed!