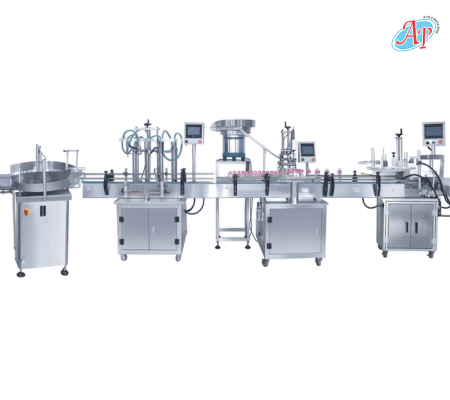

The Fully Automatic Filling Line is an integrated packaging solution that combines filling, capping, and labeling into a seamless, high-speed operation. Ideal for pharmaceutical, nutraceutical, cosmetic, and chemical industries, this system is designed to handle high volumes with unmatched precision and hygiene. Whether you are packaging syrups, suspensions, hand sanitizers, eye drops, or lotions, this automated line ensures GMP-compliant output with reduced human intervention.

At AmarPack Machines Pvt Ltd, a leading Filling Line Manufacturer in India, we build fully automatic systems tailored to your container size, product type, and output requirement. The system includes servo or volumetric-based liquid filling machines, automatic cap feeders with torque-controlled capping units, and high-speed sticker labeling machines. Designed with stainless steel contact parts, the machine ensures hygienic product handling and easy maintenance—ideal for pharma environments.

From Baddi to Ahmedabad, Hyderabad to Mumbai, our filling lines are widely used across India’s pharmaceutical manufacturing clusters for their efficiency, flexibility, and scalability.

| Parameter | Details |

|---|---|

| Filling Range | 30ml to 1000ml (customizable for each project) |

| Capping Type | Screw, ROPP, CRC, Snap-fit (Interchangeable Heads) |

| Labeling Speed | Up to 150 bottles per minute (depending on bottle size) |

| Construction Material | SS 304/316 (GMP compliant) |

| Power Supply | 230V / 415V, 50Hz, Single or Three Phase |

Pharmaceutical Industry – Ideal for antibiotics, syrups, and OTC medications.

Nutraceutical Sector – Bottling of immunity boosters, herbal extracts, and supplements.

Cosmetics & Personal Care – Efficient packaging for lotions, serums, and gels.

Chemical & Agrochemical – Suitable for packaging pesticides, disinfectants, and chemicals.

Veterinary Pharma – Liquid animal medicines and tonics filled hygienically and accurately.

Complete Automation: Reduces labor cost and minimizes manual errors.

High Throughput: Designed to handle up to 100–150 BPM depending on bottle and fill size.

Regulatory Compliance: Built to meet US FDA, EU GMP, and Indian Schedule-M guidelines.

Scalable System: Easily expandable with infeed/outfeed conveyors, turntables, and vision inspection.

Cleanroom Compatible: Stainless steel GMP construction for use in ISO-classified areas.

Yes, it supports PET, HDPE, and glass bottles with appropriate holding mechanisms.

Yes, quick-change parts and programmable settings allow for multi-product operations.

Screw caps, ROPP caps, CRC, snap-fit, and press-fit caps with torque adjustment.

Absolutely, our line can be synchronized with upstream/downstream equipment.

Typically under 15 minutes with tool-less design and recipe-based auto adjustment.

Yes, the labeling system can be customized to apply wrap-around, front-back, or panel labels on various bottle shapes including round, flat, and oval containers with high precision.

Founded in 1998 in Mumbai, India, AmarPack Machines Pvt. Ltd. is one of India’s leading manufacturers and exporters of premium packaging machines. Read More

GST No. 27AAZCA2345J1Z6

Get a quick quote from our experts. Fast response guaranteed!