- All Posts

- Activities

- Blog

- Events

- Health

- Nursing

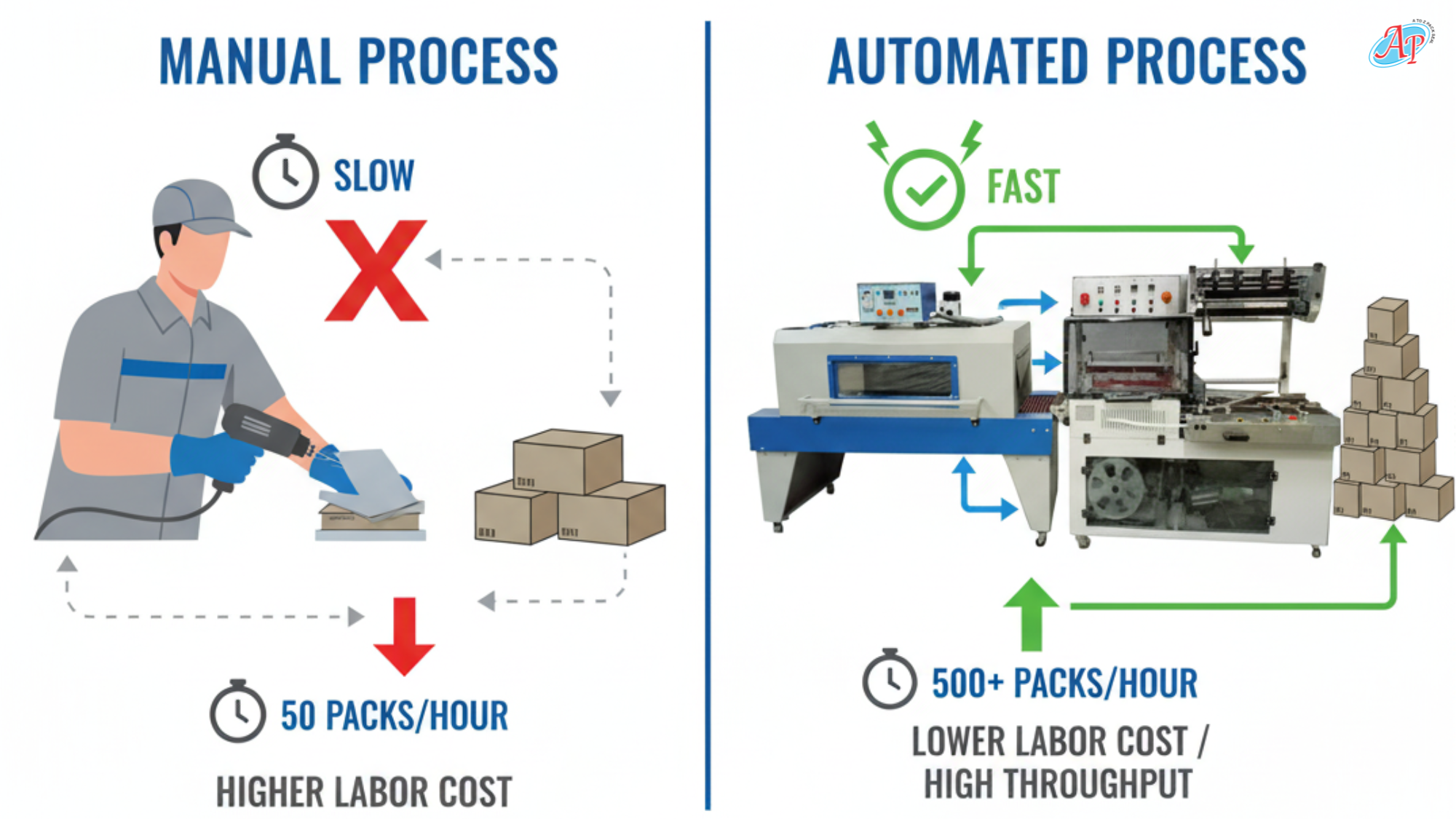

Automatic L-Sealer with Shrink Tunnel Machine: Complete Guide to Industrial Shrink Wrapping Automation Automatic L-Sealer with Shrink Tunnel | Industrial...

Choosing the Right Steam Heat Shrink Tunnel Machine for High-Volume Packaging Lines India’s packaging sector is among the fastest-growing, with...

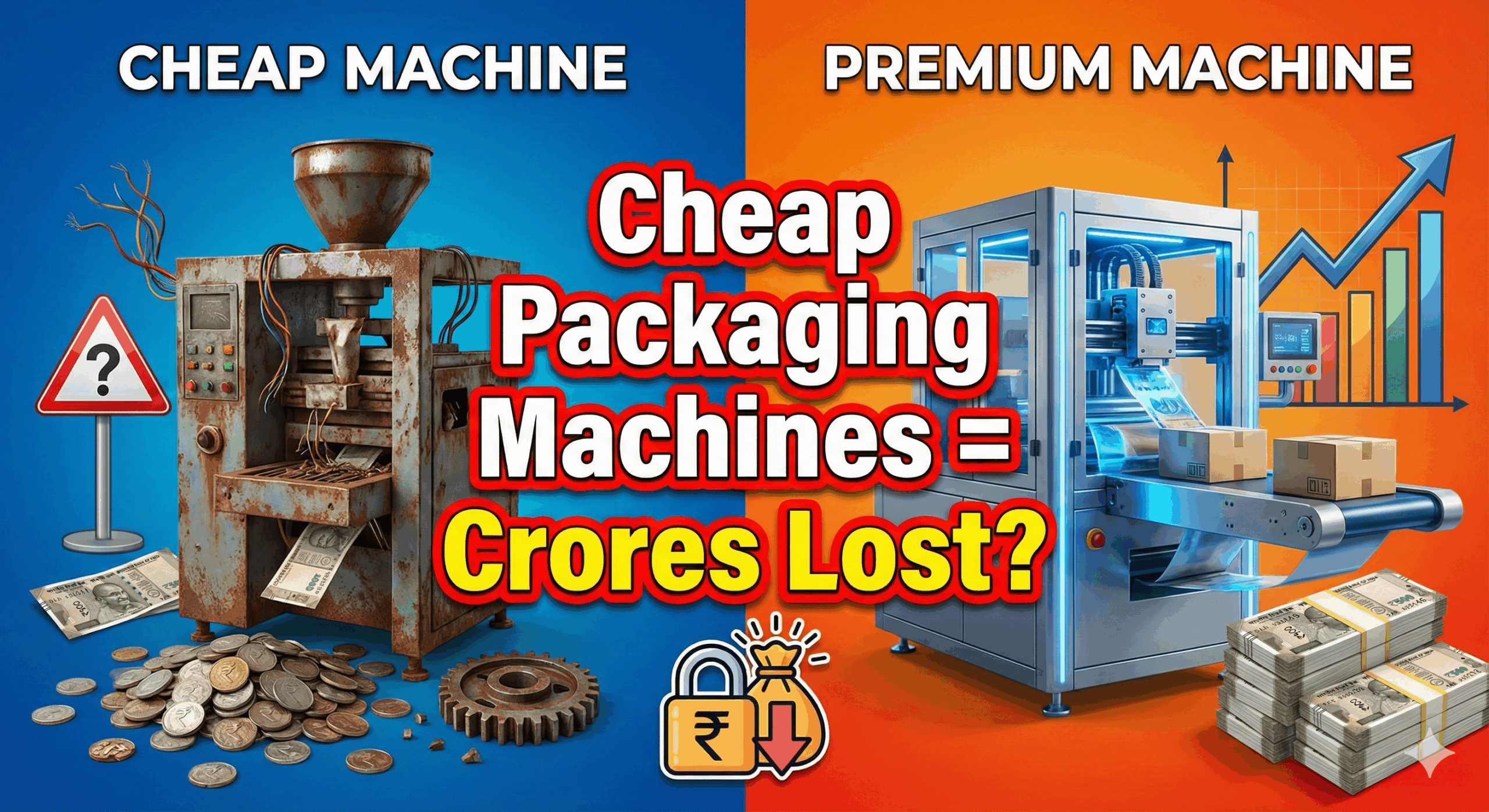

Why Cheap Packaging Machines Cost Indian Manufacturers Crores Heat Shrink Packaging Technology: Benefits, Cost Breakdown & ROI Guide 2025 Ai...

Why Your Packaging Line Needs Heat Shrink Technology: Benefits, Cost & Real-World Examples (2025 Guide) Heat Shrink Packaging Technology: Benefits,...

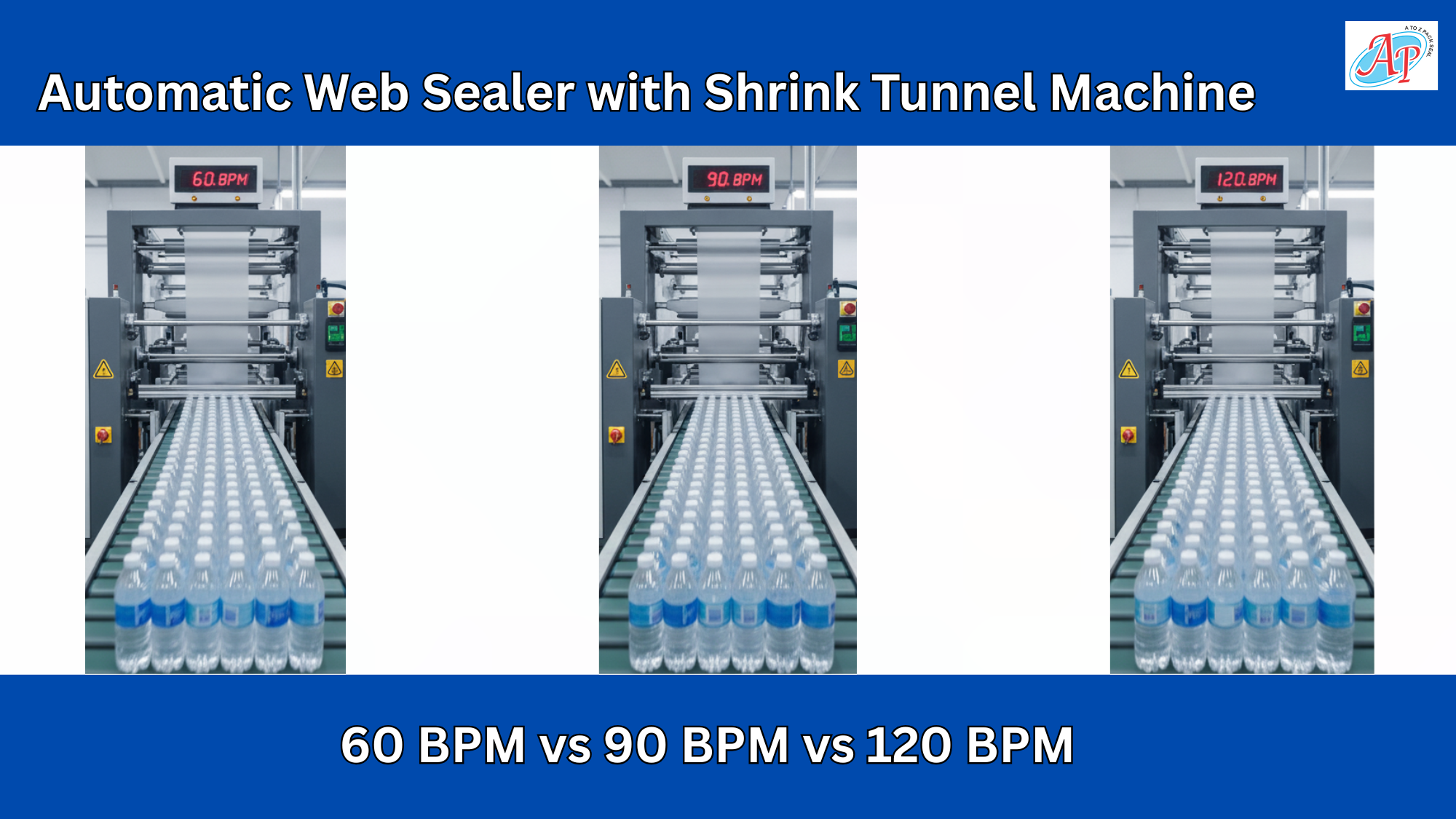

The Essential Guide to Choosing Your Web Sealer With Shrink Tunnel: 60 BPM vs 90 BPM vs 120 BPM Capacity...

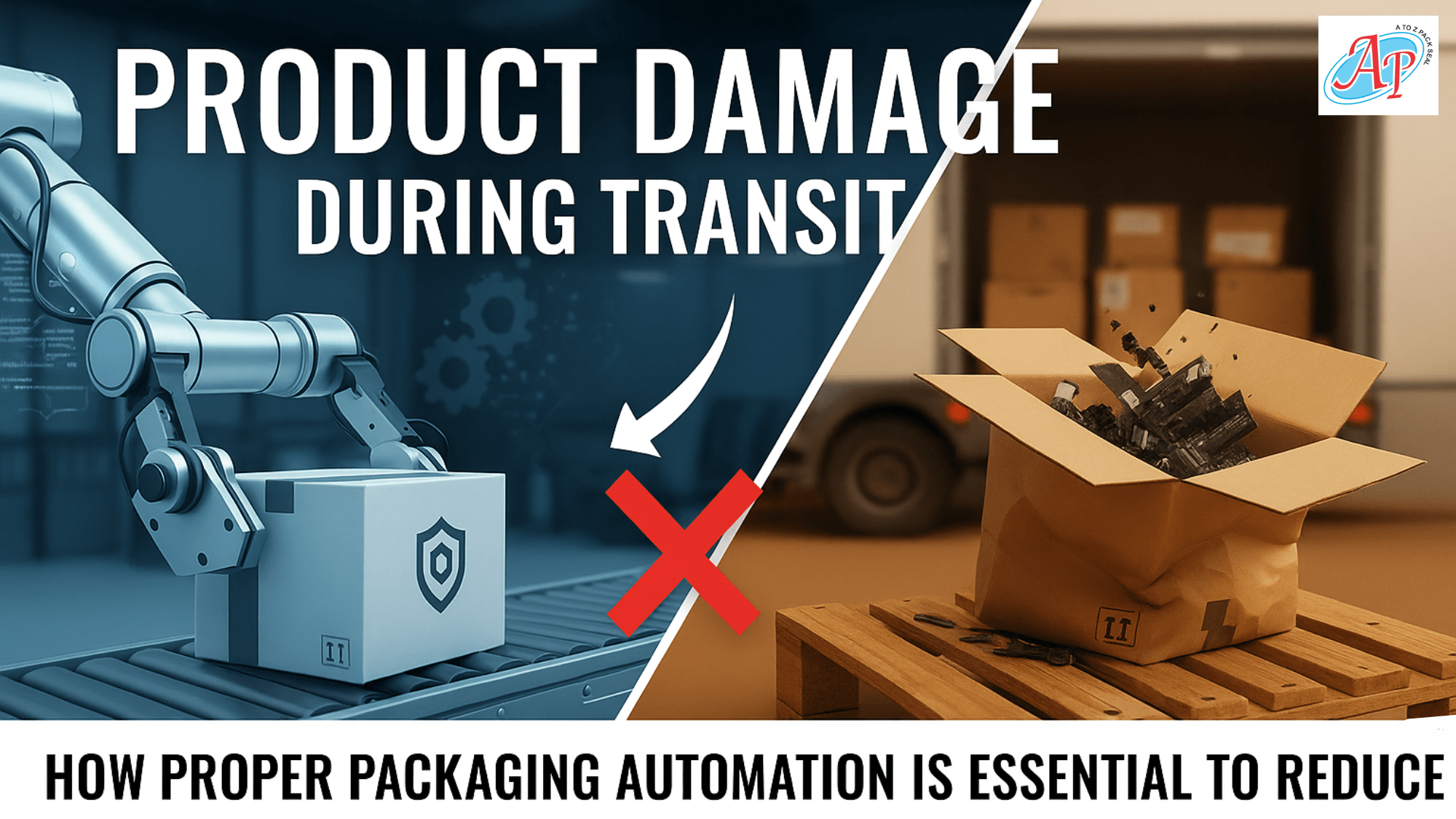

How Proper Packaging Automation is Essential to Reduce Product Damage During Transit How Packaging Automation Help Reduce Product Damage During...

How an Automatic Web Sealer with Shrink Tunnel Revolutionises Rice Bag Group Packaging in India Automatic Web Sealer with Shrink...

Why Fully Automatic Shrink Wrapping Machines Are Becoming a Global Standard in 2025 Global Packaging Automation Trends 2025 | Fully...

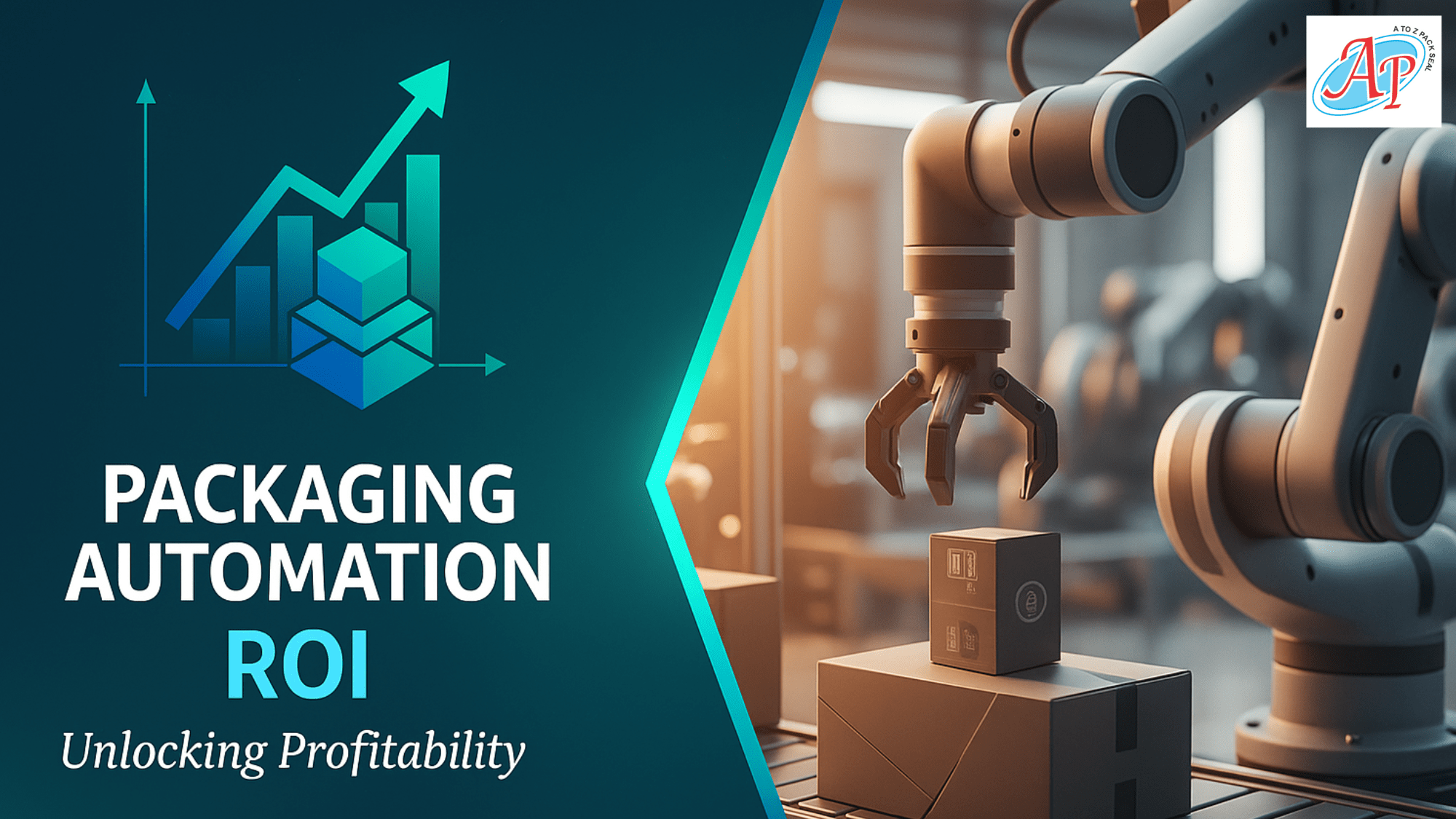

Packaging Automation ROI Calculator: Real Cost Savings for Indian Manufacturers in 2025 Packaging Automation ROI Calculator (2025) | Real Cost...