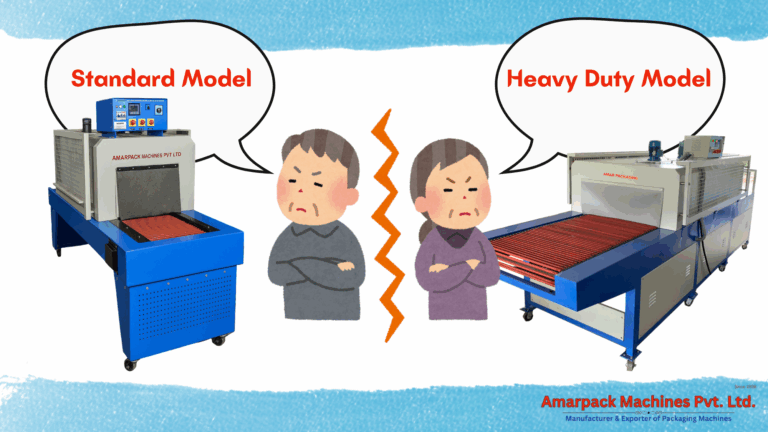

Choosing between a Standard Shrink Wrapping Machine and a Heavy-Duty Shrink Wrapping Machine can define the speed, durability, and efficiency of your entire packaging line. Whether you’re running an FMCG, food & beverage, or industrial production unit, understanding these differences ensures you invest in a system that matches your exact packaging needs.

In this guide, we’ll break down both machine types — exploring their features, applications, technical differences, and ideal use cases — so you can confidently select the right model for your operation.

Shrink wrapping machines use heat to shrink a plastic film tightly around products, providing protection, tamper resistance, and a polished retail finish.

At AmarPack Machines Pvt Ltd, we design three core variants:

Portable (APST-100): Compact and mobile for small batches.

Standard (APST-200): Ideal for medium-scale continuous packaging.

Heavy-Duty (APST-300): Built for high-volume, industrial-strength operations.

This blog focuses on comparing the APST-200 Standard Shrink Wrapping Machine and APST-300 Heavy-Duty Shrink Wrapping Machine, two of India’s most trusted models.

The Standard Shrink Wrapping Machine (Model: APST-200) is engineered for medium-volume production units requiring consistency, versatility, and reliability.

Adjustable speed from 6–20 packs per minute

Precision-controlled heating system (0–300°C)

Fully recirculating air tunnel for uniform shrinking

Compatible with LDPE/LLDPE films of various thicknesses

Low power consumption and smooth live roller conveyor system

FMCG and retail multipacks

Bottled water and beverage packaging

Pharmaceuticals and personal care containers

Medium-sized factories seeking dependable daily output

🟢 Learn more about this model:

Standard Shrink Wrapping Machine – APST-200

The Heavy-Duty Shrink Wrapping Machine (Model: APST-300) is built for continuous, large-scale industrial packaging. Designed with rugged construction and high-capacity tunnels, it delivers unmatched performance for operations demanding 24/7 productivity.

Power-packed 9–10 KW heating system

18″–20″ tunnel opening for larger or bulkier products

Enhanced air circulation for even shrink results at high speeds

Supports high-thickness LDPE films for maximum protection

Heavy-duty conveyor for large cartons, bottles, or industrial components

Bulk packaging units (food, beverage, chemical, lubricants)

Industrial goods and logistics companies

Export-grade packaging requiring durability and visual consistency

🟢 Learn more about this model:

Heavy Duty Shrink Wrapping Machine – APST- 300

| Specification | Standard (APST-200) | Heavy-Duty (APST-300) |

|---|---|---|

| Production Scale | Medium | Large / Continuous |

| Speed | 6–20 packs per minute | 15–40 packs per minute |

| Tunnel Size | 12″ x 12″, 14″ x 14″, 16″ x 14″ | 18″ x 16″, 20″ x 18″ |

| Power | 9 KW, 3 Phase | 9–10 KW, 3 Phase |

| Film Type | LDPE / LLDPE | LDPE (High Thickness) |

| Motor | ½ HP | 1 HP |

| Structure | Mild Steel / Optional SS | Heavy-Duty MS Body |

| Best For | Medium-volume FMCG & pharma packaging | Industrial, export, and bulk operations |

Selecting between the Standard and Heavy-Duty shrink wrapping machines depends on your production capacity, product type, and operational goals.

Have medium-scale daily output (up to 1,200 packs/day).

Need flexibility to handle different product sizes.

Want a cost-effective, energy-efficient system.

Operate in FMCG, pharma, or retail sectors.

Run a high-volume production line (1,200–2,500 packs/day).

Require continuous operation with minimal downtime.

Use high-thickness films or package heavy cartons and bottles.

Manage industrial or export packaging operations.

For over 25 years, AmarPack Machines Pvt Ltd has been India’s trusted Shrink Wrapping Machine Manufacturer , providing customized packaging solutions to more than 1000+ industrial clients across India and abroad.

ISO 9001:2015 & CE Certified Manufacturing

In-house engineering and R&D

24/7 nationwide service & technical support

Proven track record of performance and ROI

Custom design options — from conveyor extensions to PLC control

Explore our complete range:

➡️ Shrink Tunnel Machines

➡️ Web Sealer with Shrink Tunnel

➡️ L-Sealer with Shrink Tunnel

Both Standard and Heavy-Duty Shrink Wrapping Machines deliver exceptional results — but the right choice depends on your production volume and product mix.

If you’re a mid-sized manufacturer looking for efficiency, cost savings, and professional-grade packaging, the APST-200 Standard Shrink Wrapping Machine is your perfect match.

For industrial-scale packaging lines demanding 24/7 reliability, choose the APST-300 Heavy-Duty Model for superior durability and performance.

Since 1998, Amar Packaging has been helping pharmaceutical companies across India and worldwide with reliable packaging solutions. With over two decades of experience, they understand exactly what pharma businesses need.

Located in Mumbai, India’s pharmaceutical hub, Amar Packaging has direct access to the latest technology and skilled technicians. This means better service and faster support for your business.

Direct manufacturer pricing eliminates middleman costs, giving you better value for your investment.

Customization options ensure you pay only for features you actually need

Free consultation helps you choose the right machine for your specific needs without any pressure to buy.

Installation and training services ensure your team knows how to operate and maintain the equipment properly.

Ready to optimize your packaging line? Request a quote for an automatic shrink-wrapping machine or download our spec sheet to compare models and film options. Contact AmarPack Machines Pvt Ltd today for professional guidance.

Founded in 1998 in Mumbai, India, AmarPack Machines Pvt. Ltd. is one of India’s leading manufacturers and exporters of premium packaging machines. Read More

GST No. 27AAZCA2345J1Z6

Get a quick quote from our experts. Fast response guaranteed!