Whether you’re running a boutique spice manufacturing unit in Kerala or operating a high-volume pharmaceutical plant in Gujarat, selecting the right vacuum packing machines is crucial for product integrity, regulatory compliance, and profitability. This comprehensive 2025 guide showcases Amarpack Machines Pvt Ltd’s complete range of vacuum Packing Machines solutions, covering everything from compact tabletop units for small businesses to heavy-duty double chamber systems for industrial operations. All pricing information is sourced from verified manufacturer data and marketplace listings from July 2024 to July 2025.

1. Introduction to Amarpack Machines Pvt Ltd

2. What is a vacuum Packing Machines?

3. Types of Vacuum Packaging Machines by Amarpack

4. Top 10 Vacuum Packaging Solutions – Detailed Review

5. Industry Applications & Use Cases

6. Price-to-Performance Analysis

7. Integration with Other Packaging Systems

8. Why Choose Amarpack Machines Pvt Ltd?

9. Conclusion & Contact Information

10. Frequently Asked Questions

Amarpack Machines Pvt Ltd has been a trusted name in India’s packaging machinery industry since 1998, with over 27 years of experience in manufacturing and exporting high-quality packaging solutions . Based in Mumbai, Maharashtra, the company operates from their state-of-the-art facility in Naigaon East, Vasai, serving clients across 120+ countries worldwide . The company specializes in manufacturing vacuum packaging machines, shrink wrapping systems, sealing machines, and filling equipment for diverse industries including food processing, pharmaceuticals, FMCG, chemicals, and export packaging . With an annual turnover of ₹425 crores and a team of skilled professionals, Amarpack has established itself as a leading packaging machinery manufacturer in India .

A vacuum Packing Machines removes air from packaging pouches or containers and creates

an airtight seal, preventing oxidation, bacterial growth, and moisture ingress . This process

significantly extends product shelf life by 25 times compared to conventional packaging

methods .

Fresh vegetables vacuum sealed in a clear plastic bag with creamy portions, illustrating vacuum

packaging for food preservation.

The vacuum sealing process involves placing products in specialized plastic pouches, extracting

air using powerful vacuum pumps, and heat-sealing the package to create a tamper-proof,

contamination-free environment. Modern vacuum packaging machines can achieve vacuum

levels of less than 1 kPa, ensuring optimal preservation conditions .

Amarpack Machines Pvt Ltd offers a comprehensive range of vacuum packaging solutions designed to meet diverse industry requirements: Table Top Vacuum Packaging Machines Compact, space-saving units ideal for small businesses, restaurants, and retail operations . 8 Dz260 Table-Top Vacuum Sealing Machine for small business food packaging featuring digital controls and a clear vacuum chamber

Compact, space-saving units ideal for small businesses, restaurants, and retail operations .

Dz260 Table-Top Vacuum Sealing Machine for small business food packaging featuring digital

controls and a clear vacuum chamber.

Medium-capacity systems designed for industrial applications requiring consistent high-volume

packaging

Nozzle Type Vacuum Packaging MachinesAdvanced systems featuring external nozzle operation, perfect for liquid products and

oversized packaging

High-efficiency systems with parallel processing capabilities for maximum productivity Yupack Dz600/2s commercial vacuum packaging machine for industrial food processing and

packaging.

| Rank | Model Name | Key Specifications | Best Applications |

|---|---|---|---|

| 1 | APTT Table Top | 16m³/h pump, 400mm seal, 95kg | Small restaurants, spice units |

| 2 | APVC Commercial | 100–300m³/h pump, 1200mm seal, 450kg | Medium food processing |

| 3 | APNV Nozzle Type | 16–65m³/h pump, PLC HMI, gas flush | Liquid products, pharmaceuticals |

| 4 | APVC Vertical Chamber | 40–100m³/h pump, 650mm seal, PLC | Bulk packaging, export |

| 5 | APDC Double Chamber | 40–100m³/h pump, 600mm seal, 350kg | High-volume operations |

| 6 | APNVH Table Nozzle | 8m³/h pump, 450mm seal, portable | Flexible packaging needs |

| 7 | APST Commercial Plus | Heavy-duty design, mobility wheels | Industrial applications |

| 8 | APVC Pharma Grade | SS304 construction, GMP compliance | Pharmaceutical packaging |

| 9 | APDC Heavy Duty | 100m³/h pump, multiple sealing bars | Contract packaging |

| 10 | APVC Export Model | Customizable dimensions, export specs | Large-scale export operations |

Amarpack’s vacuum Packing Machines serve diverse industries with specific packaging requirements:

Food & Beverage Industry

The largest segment utilizing vacuum Packing Machines for spices, ready-to-eat meals, dry fruits, and snacks. Amarpack’s table top and commercial models are particularly popular for extending shelf life from 6 months to 23 years for various food product. Detailed vacuum sealed food shelf life chart showing storage durations for meats, vegetables, fruits, baked goods, liquids, dry food, and spices under different conditions.

Pharmaceutical Industry

Sterile packaging requirements for tablets, capsules, APIs, and medical instruments demand precise contamination control. Amarpack’s nozzle-type and commercial models ensure GMP compliance and maintain sterility throughout the packaging process Sterile medical device packaging with syringe and tubing held by gloved hands illustrating pharmaceutical vacuum Packing Machines.

Export & Logistics

Growing demand for export-quality packaging has made vacuum sealing essential for international shipments. Amarpack’s vertical and double-chamber machines optimize container space while providing moisture and contamination protection Large machinery item vacuum sealed and wrapped in aluminum foil packaging on a wooden pallet for export.

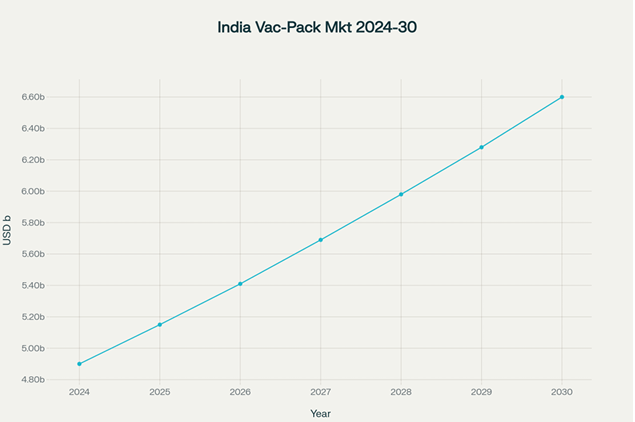

The Indian vacuum Packing Machines market is experiencing steady growth, with the sector valued at USD 4.9 billion in 2024 and projected to reach USD 6.60 billion by 2030 at a 5.1% CAGR. Projected growth of India’s vacuum packaging machine market from 2024 to 2030

Investment Considerations:

Entry-Level Solutions (₹1.53 Lakhs): Amarpack’s table top models offer excellent ROI for small businesses, typically recovering investment within 1218 months through reduced product wastage .

Mid-Range Systems (₹35 Lakhs): Commercial and nozzle-type machines provide versatility and higher throughput, suitable for growing businesses requiring 3001000 packs per day.

High-End Solutions (₹58 Lakhs): Double-chamber and specialized systems deliver maximum efficiency for large-scale operations, with payback periods of 1824 months due to labor savings and increased productivity

Amarpack’s vacuum packing machines integrate seamlessly with complementary packaging

equipment:

Since 1998, Amarpack has delivered over 25,000+ packaging solutions to satisfied customers worldwide, building an unmatched reputation for quality and reliability

All machines meet ISO 9001, FSSAI, BIS, and CE certification requirements, ensuring seamless

regulatory approval

State-of-the-art 35,000 sq ft manufacturing facility with advanced CNC fabrication, ensuring

consistent quality and competitive pricing

From compact ₹1.68 lakh table top units to industrial ₹7+ lakh systems, Amarpack offers

solutions for every business size and requirement

Proven track record in 120+ countries with specialized export packaging and documentation

support

Investing in the right vacuum packing machine is crucial for product quality, shelf life extension, and business growth. Amarpack Machines Pvt Ltd offers India’s most comprehensive range of vacuum Packing Machines solutions, from affordable ₹1.68 lakh table top units to advanced ₹7+ lakh industrial systems.

With 27+ years of manufacturing excellence, 25,000+ satisfied customers worldwide, and nationwide service support, Amarpack stands as your trusted partner for all packaging machinery needs.

Our reputation as a top-tier packaging machine manufacturer in Mumbai is built on several pillars that set us apart:

Innovation & Technology: We continuously invest in R&D to bring the most advanced and efficient packaging automation technology to our clients in Maharashtra.

Uncompromising Quality & Durability: Every packaging machine from our Mira Bhayandar factory is built with premium materials and undergoes rigorous quality checks, ensuring longevity and reliability.

Proven Track Record & Customer Success: We have a strong portfolio of successful installations and satisfied clients across diverse industries in Mumbai, Thane, Navi Mumbai, Pune, Nashik, Aurangabad, and beyond. (Consider linking to a “Case Studies” page here if applicable).

Dedicated Customer Support: From initial consultation to post-installation support, our team is committed to providing seamless and responsive service.

Competitive Pricing & ROI: We offer cost-effective packaging machine solutions that deliver excellent return on investment through increased efficiency and reduced operational costs.

We are not just a packaging machine supplier; we are your strategic partner, committed to enhancing your production capabilities and helping you thrive in the dynamic Mumbai and Maharashtra markets.

Contact AmarPack Machines Pvt Ltd today, your trusted packaging machine manufacturer in Naigaon, Mumbai, Maharashtra. Let’s discuss your unique requirements and find the perfect packaging solution for your business near Mumbai and beyond.

Founded in 1998 in Mumbai, India, AmarPack Machines Pvt. Ltd. is one of India’s leading manufacturers and exporters of premium packaging machines. Read More

GST No. 27AAZCA2345J1Z6

Get a quick quote from our experts. Fast response guaranteed!