In the rapidly evolving world of packaging, automation has become more than just a convenience—it is now a necessity for scaling businesses, ensuring consistent quality, and reducing operational costs. Among the leading innovations in this sector is the Automatic Web Sealer with Shrink Tunnel Machine, particularly for box packaging applications. This powerful combination is transforming packaging lines across industries, helping manufacturers meet high-volume demands with speed, precision, and efficiency.

In this comprehensive guide, we explore the working principle, features, benefits, industry use cases, and future relevance of the Automatic Web Sealer with Shrink Tunnel Machine—the go-to solution for professional, industrial-grade box packaging.

An Automatic Web Sealer is a high-speed packaging system designed to wrap products—typically boxes or cartons—in a heat-shrinkable poly film. The Shrink Tunnel is attached right after the sealing process and functions by applying controlled heat to shrink the film tightly around the package.

Together, these machines provide seamless, automated, and tamper-proof packaging for bulk boxes, cartons, and other rigid-shaped products. It’s an essential system for industries where packaging integrity and visual appeal matter.

Feeding: Boxes are automatically fed into the web sealer via a conveyor system.

Film Wrapping: The machine envelops the box using a center-folded shrink film (usually LDPE or Polyolefin).

Sealing: The web sealer uses a high-quality sealing mechanism (typically hot bar or L-bar) to seal and cut the film.

Shrink Tunnel: The sealed box moves into the Shrink Tunnel, where uniform heat is applied to shrink the film tightly around the box.

Cooling & Discharge: The box exits the tunnel, cools, and is ready for stacking, transport, or display.

The Automatic Web Sealer with Shrink Tunnel Machine is widely used in:

FMCG & Consumer Goods

Pharmaceuticals

Food & Beverage

E-commerce & Logistics

Stationery & Printing Industry

Cosmetics and Personal Care

Automotive Components

Electrical and Electronics Packaging

Whether it’s bundling multiple cartons or individually wrapping boxes for shipping, this machine ensures durability and professional presentation.

| Parameter | Specification |

|---|---|

| Sealing Type | Web Sealing with L-bar or Hot Knife |

| Shrink Tunnel Temp Range | 80°C – 250°C (Adjustable) |

| Conveyor Speed | 0–15 meters/min |

| Film Material | LDPE / PVC / POF |

| Max Product Dimensions | Up to 800mm width × 400mm height |

| Power Supply | 3 Phase, 440V, 50/60Hz |

| Construction | Powder-coated MS / Stainless Steel |

| Control System | PLC-based with HMI (optional |

Note: Specifications vary by model. At AmarPack Machines Pvt Ltd, we offer customized solutions based on your product size and throughput requirements.

1. Higher Packaging Speeds

Automates repetitive tasks and significantly increases throughput compared to manual or semi-automatic systems.

2. Cost-Efficiency

Reduces labor requirements, minimizes film wastage, and lowers long-term operational costs.

3. Professional Finish

Delivers a neat, uniform, and tamper-evident finish that improves product appearance and shelf value.

4. Product Protection

Shrink-wrapped boxes are better protected against dust, moisture, and tampering during transport and storage.

5. Customizable for Different Sizes

The machine is designed to handle a wide range of box sizes and shapes, allowing flexibility in packaging.

6. Seamless Integration

Can be integrated with automated conveyor systems, labelers, or coders for a fully automated packaging line.

In an age where time, consistency, and quality are key business metrics, the Automatic Web Sealer with Shrink Tunnel Machine checks all the boxes:

Reduces manual dependency

Enhances workplace safety

Improves packaging reliability

Supports large-scale production

Complies with export-grade packaging standards

As e-commerce, automation, and supply chain demands continue to rise, businesses that adopt automatic shrink wrapping solutions are far better positioned to scale efficiently.

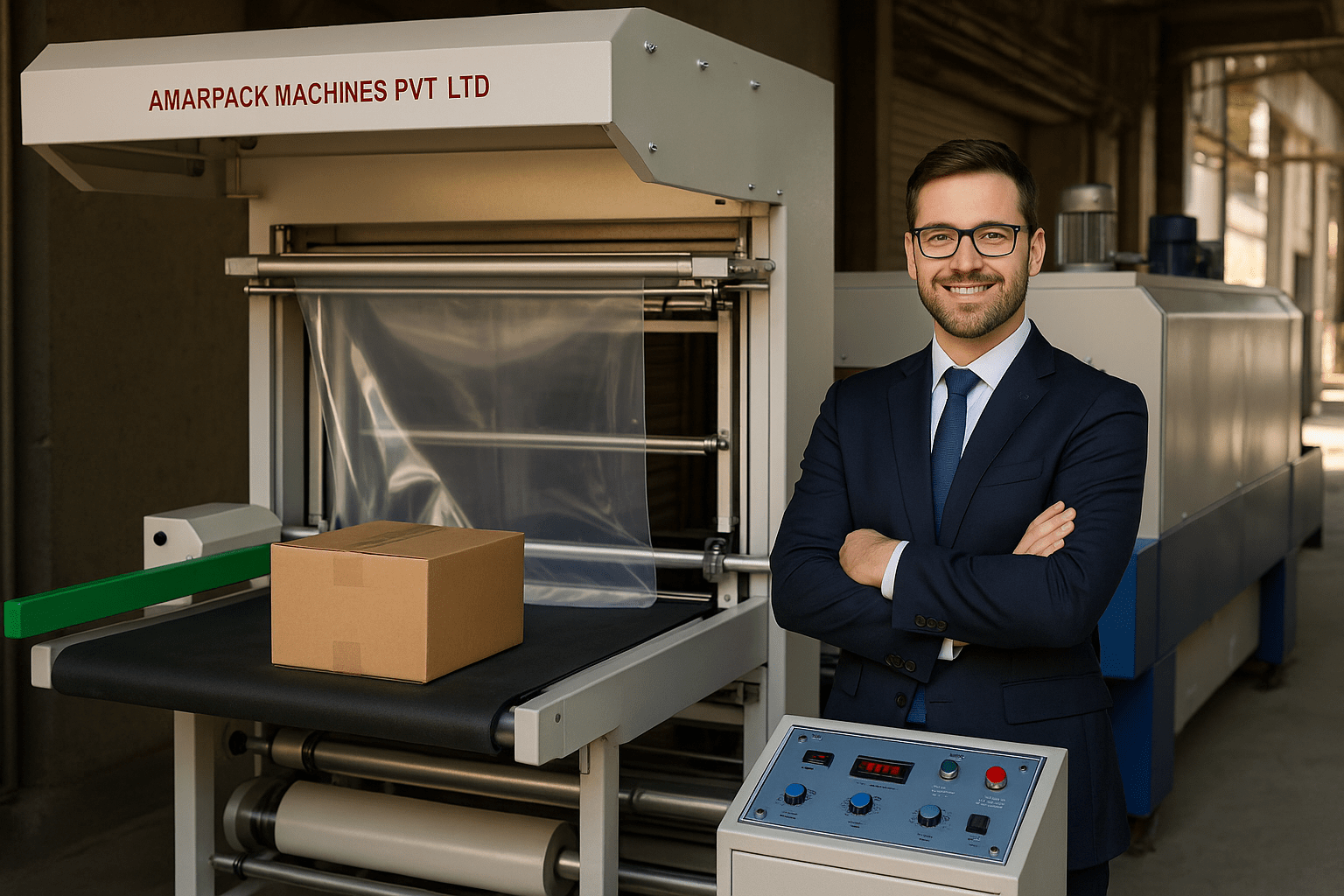

When it comes to packaging automation, experience matters. AmarPack Machines Pvt Ltd is a trusted name in India and internationally for high-performance, durable, and customizable packaging solutions.

What Sets Us Apart:

Over 25+ years of manufacturing expertise

International quality standards (exported to 30+ countries)

Tailor-made solutions for industry-specific needs

24/7 service support and trained technicians

Prestigious clientele including Colgate, Cipla, Flipkart, Marico, L&T, and more

An Automatic Web Sealer with Shrink Tunnel Machine is used to wrap and seal boxes or cartons in heat-shrinkable film, creating tamper-evident and protective packaging. It’s widely used in industries such as FMCG, pharmaceuticals, e-commerce, and food & beverage for bulk and individual box packaging.

Most machines are compatible with LDPE (Low-Density Polyethylene), POF (Polyolefin), and PVC shrink films. These materials offer strong protection, high shrink performance, and clear packaging ideal for retail and industrial use.

Yes. The machine is designed to handle a wide range of box sizes. Models with adjustable guides and conveyors can accommodate small to large boxes, making them versatile for varied packaging requirements.

The automated system drastically reduces manual labor, speeds up the packaging process, ensures uniformity, and minimizes film wastage. This leads to faster output, lower costs, and a professional finish on every box.

AmarPack Machines Pvt Ltd offers over 25 years of experience, exports to 30+ countries, and provides custom-built machines tailored to your production needs. With top-tier service, durable machinery, and a trusted client base including Colgate, Cipla, and Flipkart, you’re choosing reliability, performance, and ROI.

Founded in 1998 in Mumbai, India, AmarPack Machines Pvt. Ltd. is one of India’s leading manufacturers and exporters of premium packaging machines. Read More

GST No. 27AAZCA2345J1Z6

Get a quick quote from our experts. Fast response guaranteed!