Call On: +91 9821778504 | +91 7028578378

GST No: 27AACCA8775E1Z7

In today’s fast-paced packaging industry, speed, precision, and hygiene have become non-negotiable. As a result, more and more businesses are shifting to automatic tube filling and sealing machines to upgrade their production lines. Whether you’re in the cosmetics, pharmaceutical, food, or chemical industry, chances are your competitors are already investing in automation — and for good reason.

If you’re still using manual or semi-automatic tube fillers, you’re falling behind. Let’s explore the top 5 reasons why smart businesses are investing in automatic tube filling and sealing machines — and why you should consider doing the same.

Automatic tube filling and sealing machines are designed to dramatically improve the speed and efficiency of your packaging process. The automation allows for continuous, high-speed filling and sealing of tubes, making it possible to achieve hundreds to thousands of units per hour, depending on the model. This is a significant improvement over manual or semi-automatic systems, where speed is often limited by human labor.

How Automation Transforms Your Production Line:

This increased speed and efficiency mean you can meet market demand faster, reduce delivery times, and scale your operations more easily.

In industries like pharmaceuticals, cosmetics, and food, maintaining high-quality standards is paramount. Inconsistent fill volumes, poorly sealed tubes, and defective products can result in customer dissatisfaction, returns, and regulatory issues. One of the most significant advantages of investing in an automatic tube filling machine is its ability to deliver precision and consistent quality in every unit produced.

Key Features That Ensure Consistent Quality:

These machines offer repeatable precision, which is vital for companies striving to build their brand’s reputation for quality.

As a business in the pharmaceutical or personal care industry, compliance with hygiene, safety, and regulatory standards is non-negotiable. Automatic tube filling machines are designed with these concerns in mind. Many of these machines are GMP-compliant (Good Manufacturing Practice) and built with hygienic materials like stainless steel and food-grade components to ensure your production line adheres to the highest standards.

How Automatic Machines Ensure Hygiene and Compliance:

Easy to clean surfaces: Stainless steel construction allows for quick and thorough cleaning, reducing the risk of contamination between batches.

Clean-In-Place (CIP) technology: These systems ensure that all contact parts can be sanitized without disassembling the machine, preventing product contamination.

FDA and GMP-compliant designs: Many automatic tube filling and sealing machines are manufactured to meet international standards, ensuring your business stays compliant with industry regulations.

By investing in automatic tube filling equipment, you’re not only improving your operational efficiency but also ensuring your products meet the strict hygiene and safety regulations required for the pharma and cosmetic industries.

One of the biggest expenses for manufacturers is labor. Manual tube filling and sealing require multiple workers for each step of the process, including filling, sealing, labeling, and packing. In contrast, automatic tube filling and sealing machines can handle the entire process with minimal manual intervention. This leads to significant savings in labor costs while also reducing the risks of human error.

Benefits of Reduced Labor Dependence:

Lower operational costs: With fewer workers required for the same output, companies can reduce their labor expenses significantly.

Fewer errors: Automation ensures that the filling, sealing, and labeling processes are done correctly every time, avoiding costly mistakes.

Streamlined operations: One operator can oversee multiple machines, making it possible to scale production without proportionally increasing labor.

Investing in automation means your business can achieve more with less and focus on value-added activities that drive growth, rather than spending resources on repetitive manual tasks.

One of the standout features of modern automatic tube filling and sealing machines is their flexibility. These machines are designed to handle various types of tube materials such as plastic, laminated, and aluminum tubes, and can work with a variety of product types including liquids, creams, gels, pastes, and semi-solids.

How Adaptability Adds Value:

Multi-product handling: Whether you are packaging pharmaceutical creams, cosmetic serums, or food pastes, automatic tube fillers can adapt to different products, making them a versatile solution.

Tube size flexibility: Most systems are capable of processing tubes of varying sizes, which allows businesses to diversify their product offerings.

Quick changeovers: With minimal downtime, machines can be reconfigured for different product types and packaging styles without needing major adjustments.

This adaptability means you can continue to meet changing customer demands and market trends without having to purchase multiple machines or invest in time-consuming manual setups.

As the market evolves and consumer demands increase, businesses need to stay competitive. Investing in an automatic tube filling and sealing machine ensures your company remains at the forefront of efficiency, compliance, and customer satisfaction. Whether you’re looking to increase production speed, enhance product quality, or reduce costs, automation offers a solution that delivers tangible results.

If you’ve been hesitating about making the switch, consider this: Your competitors are already benefiting from these advanced machines. Don’t fall behind — upgrade your production line today and watch your business thrive in a market that demands speed, precision, and innovation.

The decision to invest in automatic tube filling and sealing machines will not only boost your production efficiency but will also improve the quality, safety, and cost-effectiveness of your packaging process. As automation becomes the industry standard, don’t let your business fall behind. Make the move to automation and stay competitive in an ever-changing market.

Stay ahead. Automate now.

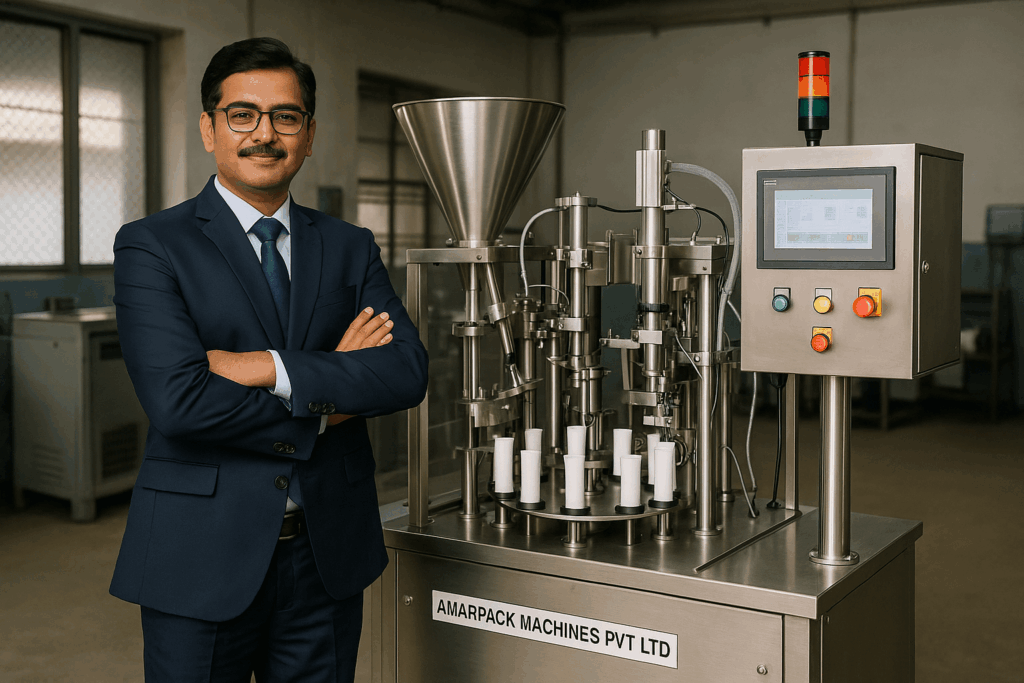

Founded in 1998 in Mumbai, India, AmarPack Machines Pvt. Ltd. is one of India’s leading manufacturers and exporters of premium packaging machines. Read More

GST No. 27AAZCA2345J1Z6

Get a quick quote from our experts. Fast response guaranteed!