Call On: +91 9821778501 | +91 7028578378

GST No: 27AACCA8775E1Z7

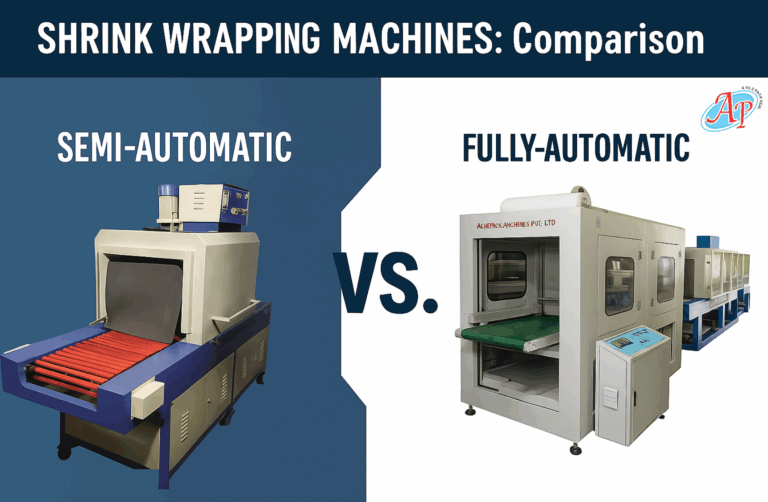

When it comes to industrial packaging automation, few decisions carry as much weight as selecting the right Shrink Wrapping Machine. The wrong investment can bottleneck production, inflate labor costs, and limit scalability—turning what should be a growth enabler into an operational liability.

This 2025 Buyer’s Guide breaks down everything you need to know about choosing between Semi-Automatic and Fully Automatic Shrink Wrapping Systems. Whether you run a growing startup or a high-volume manufacturing unit, this guide will help you make a data-driven, future-ready decision.

At the heart of this choice lie three pivotal factors:

👉 Volume — How many packages per minute you need to process.

👉 Budget — How much you can allocate for capital investment vs. long-term operating costs.

👉 Labor — How you plan to balance manual intervention with automation.

Shrink wrapping is a process that covers a product or bundle with a thermoplastic film, which shrinks tightly around it when exposed to heat. It provides a tamper-evident seal, protection from dust and moisture, and enhances retail shelf appeal.

Common industrial applications include:

Bundling bottles, cans, or cartons into multipacks.

Protecting goods during transport or storage.

Enhancing presentation for retail packaging (e.g., cosmetics, books, or software boxes).

L-Bar Sealers – Most common and cost-effective, ideal for single product packaging.

Side Sealers – Designed for continuous packaging of longer products or variable lengths.

Sleeve Wrappers (Web Sealers) – Used for wrapping trays, bottles, or bundled products together.

A Shrink Wrapping Machine primarily includes:

Sealing Mechanism: Can be pulse (instant heat sealing) or constant heat (continuous operation).

Heat Tunnel: Uses hot air circulation to shrink the film evenly, ensuring smooth and wrinkle-free packaging.

A Semi-Automatic Shrink Wrapping Machine requires manual loading and/or unloading by an operator. Once placed, the machine seals and shrinks the film automatically, making it a hybrid between manual and fully automatic systems.

Lower Initial Investment: Affordable entry point for SMEs.

High Flexibility: Handles multiple product sizes and short production runs with ease.

Compact Footprint: Ideal for small facilities or limited floor space.

Quick Changeovers: Minimal downtime when switching SKUs.

Lower Throughput: Output depends on operator efficiency.

Higher Labor Costs: Each cycle requires manual handling.

Seal Consistency: Quality may vary depending on operator skill.

Best suited for startups, contract packers, and small-scale manufacturers processing up to 15–20 packages per minute (PPM). Perfect for variable product mixes and seasonal operations.

A Fully Automatic Shrink Wrapping Machine integrates with conveyors to automate the entire process—from product feeding to sealing and shrinking. Human intervention is limited to film roll replacement and system monitoring.

Maximum Throughput: Capable of 25+ PPM, ideal for high-volume operations.

Reduced Labor Dependency: Significantly cuts manual involvement.

Precision Sealing: Consistent, professional-grade finish every time.

Designed for 24/7 Operation: Supports continuous or multi-shift production.

Longer Setup Time: Product changeovers may need configuration adjustments.

A perfect match for large-scale manufacturing, FMCG packaging, bottle bundling, or printing operations where volumes exceed 25 PPM and consistency is critical.

| Factor | Semi-Automatic | Fully Automatic |

|---|---|---|

| Initial Cost | Low | High |

| Total Cost of Ownership (TCO) | Higher over time (due to labor) | Lower per unit at scale |

| Throughput | Up to 15–20 PPM | 25–60+ PPM |

| Labor Involvement | Operator per shift | Minimal |

| Maintenance Complexity | Simple | Advanced |

| Ideal For | SMEs, variable products | High-volume, standardized packaging |

Key takeaway: If your facility is scaling and you foresee steady growth, investing in automation now will yield long-term savings and better production consistency.

A. Current & Projected Volume

Your current throughput and 3-year growth forecast should dictate the machine choice. Plan for peak loads to avoid rapid obsolescence.

B. Product and Packaging Variety

If you run multiple SKUs or frequently change packaging sizes, opt for Semi-Automatic systems. For uniform, repetitive production lines, Fully Automatic offers better efficiency.

C. Integration Requirements

Does your line include conveyors, labelers, or batch coders? A Fully Automatic Shrink Wrapping Machine can seamlessly integrate with these systems for end-to-end automation.

D. Film Considerations (2025 Trends)

Modern packaging emphasizes sustainability—machines optimized for thinner POF, LDPE, or biodegradable shrink films offer both cost and environmental benefits.

Choosing the right Shrink Wrapping Machine is not about the price tag—it’s about matching automation with your operational reality.

For low to medium production with multiple SKUs, a Semi-Automatic system ensures agility and affordability.

For high-volume, consistent operations, a Fully Automatic Shrink Wrapping Machine delivers superior ROI and packaging quality.

Many manufacturers are adopting modular automation—hybrid solutions that evolve from semi to fully automatic by adding conveyors, sensors, or robotic arms as production scales.

Since 1998, Amar Packaging has been helping pharmaceutical companies across India and worldwide with reliable packaging solutions. With over two decades of experience, they understand exactly what pharma businesses need.

Located in Mumbai, India’s pharmaceutical hub, Amar Packaging has direct access to the latest technology and skilled technicians. This means better service and faster support for your business.

Direct manufacturer pricing eliminates middleman costs, giving you better value for your investment.

Customization options ensure you pay only for features you actually need

Free consultation helps you choose the right machine for your specific needs without any pressure to buy.

Installation and training services ensure your team knows how to operate and maintain the equipment properly.

📞 Request a Free Consultation – Our export packaging specialists will analyze your current processes and recommend optimal automation solutions

🌐 Explore Our Machine Range – Visit amarpackaging.com for our complete portfolio

Contact us today: Don’t let packaging bottlenecks limit your Diwali export success. Your global customers are waiting—let’s ensure you’re ready to deliver.

Read:

Ready to optimize your packaging line? Request a quote for an automatic shrink-wrapping machine or download our spec sheet to compare models and film options. Contact AmarPack Machines Pvt Ltd today for professional guidance.

Founded in 1998 in Mumbai, India, AmarPack Machines Pvt. Ltd. is one of India’s leading manufacturers and exporters of premium packaging machines. Read More

GST No. 27AAZCA2345J1Z6

Get a quick quote from our experts. Fast response guaranteed!