Call On: +91 9821778501 | +91 7028578378

GST No: 27AACCA8775E1Z7

Packaging Machine Industry in India stands at the threshold of unprecedented transformation, driven by rapid industrialization, expanding consumer markets, and technological innovation. With the sector projected to reach $6.8 billion by 2030, growing at a robust 7.4% CAGR, packaging machines have become the backbone of modern manufacturing across FMCG, pharmaceuticals, cosmetics, food processing, and export sectors. As domestic consumption patterns evolve and global trade expands, India is positioning itself as a global hub for packaging machinery exports, with companies like AmarPack Machines leading this industrial revolution through decades of manufacturing excellence and innovation.

In today’s health-conscious environment, packaging machines ensure critical hygiene and safety standards, particularly in food and pharmaceutical industries. Automated packaging systems eliminate human contact, reducing contamination risks while maintaining sterile environments required for sensitive products. For pharmaceutical packaging, machines must comply with stringent GMP standards, ensuring every product meets regulatory requirements for patient safety.

Modern packaging machinery enables sophisticated branding capabilities that drive consumer purchasing decisions in FMCG and cosmetics sectors. Advanced labeling, printing, and sealing technologies create attractive, tamper-evident packages that enhance shelf appeal and build brand trust. Companies can now achieve consistent branding across millions of units, supporting market differentiation strategies.

Packaging automation dramatically increases production speeds while reducing manual labor requirements. Modern machines can handle 1,500-1,800 units per hour for filling and sealing operations, compared to manual processes that achieve only 200-300 units hourly. This efficiency translates to significant cost savings and faster time-to-market for products.

Bulk packaging capabilities reduce per-unit costs while improving material utilization efficiency. Automated systems optimize packaging material usage, reduce waste, and lower operational costs through consistent, precise operations that eliminate human error and material over-usage.

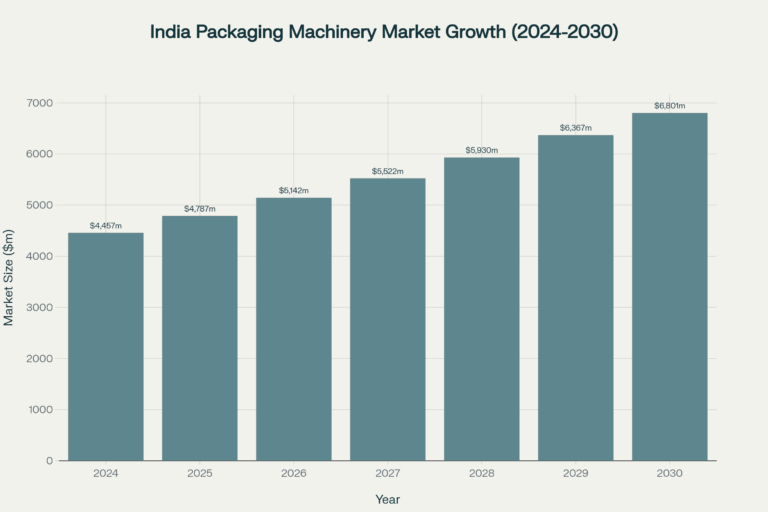

India’s packaging machinery market generated $4.457 billion in 2024 and demonstrates exceptional growth momentum. The sector benefits from India’s expanding manufacturing base, rising disposable incomes, and urbanization trends driving packaged goods consumption.

India’s packaging machinery market growth projections showing strong CAGR of 7.4% from 2024 to 2030

Indian packaging machinery manufacturers offer compelling advantages over global competitors, particularly from Europe and Japan. Lower manufacturing costs, combined with high-quality engineering and customization capabilities, make Indian machines attractive for both domestic and international markets. The country’s skilled technical workforce and established supply chains support competitive pricing while maintaining quality standards.

Mumbai & Maharashtra: India’s packaging machinery manufacturing epicenter, hosting leading companies like AmarPack, Next Packaging, and Shruti Flexipack. The region benefits from proximity to major industrial customers and established infrastructure.

Delhi & NCR: Major hub for packaging machinery suppliers and exporters, serving North Indian markets and facilitating exports to Middle East and European markets.

Gujarat: Significant manufacturing base with companies like Packmech Group in Ahmedabad, specializing in vacuum packaging solutions. The state’s pro-business environment attracts packaging machinery investments.

Bangalore & Chennai: Growing centers for advanced packaging technologies, particularly serving South Indian pharmaceutical and food processing industries.

Export Market Expansion

Indian packaging machinery exports span over 95 countries, demonstrating the industry’s global competitiveness. Key export markets include

UAE & Middle East: $37.1 billion in total trade value, with packaging machinery representing a growing segment. Cultural proximity and logistics advantages make UAE a strategic re-export hub for Indian machines.

Africa: $45 billion market with strong demand for cost-effective packaging solutions. Indian manufacturers are well-positioned to serve Africa’s growing manufacturing sector with appropriate technology and pricing.

Bangladesh: Significant export destination for packaging machinery, particularly serving the country’s expanding textile and food processing industries.

Europe & USA: Premium markets demanding high-quality, innovative packaging solutions. Indian exporters are increasingly penetrating these markets with advanced machinery offerings.

Shrink wrapping technology dominates the protective packaging segment, essential for beverage, food, and consumer goods industries. These machines provide tamper-evident sealing while reducing packaging material usage and storage space requirements. Advanced models handle 30-80 products per minute, supporting high-volume production lines. The technology is particularly valuable for e-commerce packaging, where product protection during transportation is critical.

Vacuum packaging extends product shelf life significantly, making it indispensable for food preservation and pharmaceutical applications. Modern vacuum packaging systems remove up to 99% of air content, preventing oxidation and bacterial growth. Single and double-chamber systems serve different production volumes, from small-scale operations to industrial manufacturing. The technology is expanding into new applications including medical device packaging and electronics protection.

Stretch wrapping provides secure pallet stabilization for logistics and warehousing operations. These machines ensure load stability during transportation while using minimal packaging material. Advanced systems feature automatic film cutting, consistent wrapping tension, and programmable wrapping patterns for different load types.

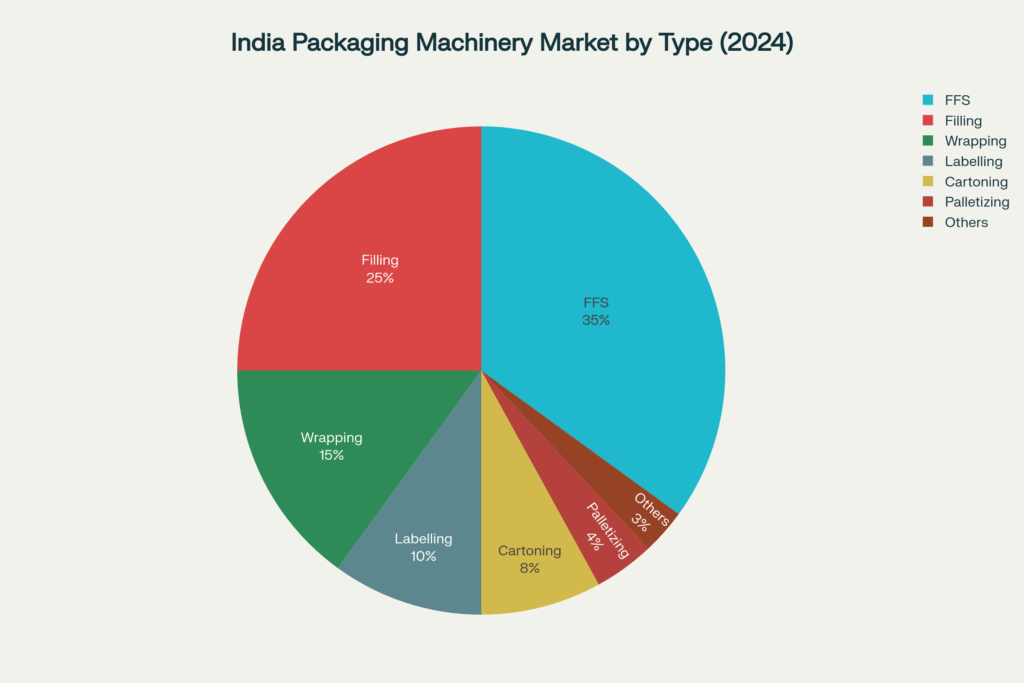

Form-fill-seal (FFS) technology represents the fastest-growing segment, combining multiple packaging operations into single-pass systems. These machines simultaneously form packages from flat film, fill with product, and seal for final packaging. Versatility across liquid, powder, and granular products makes FFS systems ideal for diverse manufacturing applications.

Market segmentation showing Form Fill & Seal and Filling machines dominating India’s packaging machinery market

Automated conveyor systems integrate with packaging lines to create seamless production workflows. Modern systems incorporate sensors, programmable controls, and real-time monitoring capabilities. Integration with Industry 4.0 technologies enables predictive maintenance and production optimization.

The Packaging Machine Industry in India is rapidly adopting Industry 4.0 technologies, with AI-powered systems enabling predictive maintenance, real-time performance monitoring, and automated quality control. Smart sensors and IoT integration allow remote monitoring and optimization of packaging operations, reducing downtime and improving efficiency. Machine learning algorithms optimize packaging parameters based on production data, ensuring consistent quality while minimizing waste.

Artificial intelligence transforms quality control through automated defect detection and real-time parameter adjustment. Vision systems powered by AI can identify packaging defects, ensuring only perfect products reach consumers. Smart sensors monitor critical parameters like sealing temperature, pressure, and speed, automatically adjusting for optimal performance.

Environmental concerns drive demand for sustainable packaging machinery capable of handling biodegradable and recyclable materials. Companies are investing in technologies that reduce packaging waste and support circular economy principles. Equipment manufacturers are developing machines specifically designed for eco-friendly materials, addressing both regulatory requirements and consumer preferences.

The e-commerce boom creates unprecedented demand for customized, durable packaging solutions. Packaging machinery must handle varied product sizes, provide tamper-evident sealing, and ensure product protection during transportation. Automated systems enable mass customization, allowing personalized packaging at industrial scales.

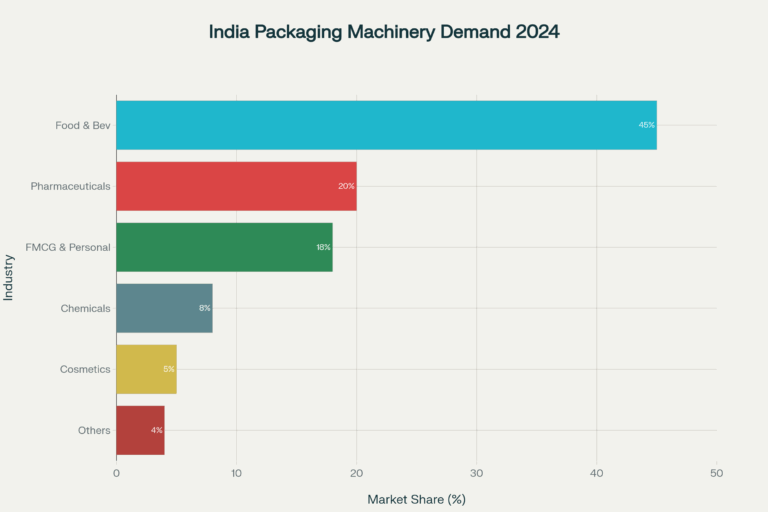

Pharmaceutical Packaging Machine Industry in India is expanding with increasing healthcare demands and regulatory requirements. FMCG sector growth, driven by rising consumer spending and brand proliferation, creates substantial packaging machinery demand. Both sectors require specialized machinery meeting stringent quality and safety standards.

Food & beverages leads packaging machinery demand, followed by pharmaceuticals and FMCG sectors.

Established in 1998, AmarPack Machines Pvt. Ltd. represents over 25 years of innovation and excellence in packaging machinery manufacturing. The company has evolved from a small-scale operation to become a trusted name across industries, serving customers throughout India and internationally. This quarter-century journey reflects consistent commitment to quality, innovation, and customer satisfaction.

AmarPack specializes in a complete range of packaging solutions including shrink wrapping machines, vacuum packaging systems, continuous band sealers, L-sealer shrink tunnel machines, and filling equipment. The company’s product diversity enables one-stop shopping for packaging requirements across multiple industries. Each product line incorporates latest technologies and industry-specific features.

AmarPack’s machines serve diverse industries including FMCG, pharmaceuticals, cosmetics, food processing, and chemicals. The company’s reputation for reliability, durability, and performance has earned trust across these demanding sectors. Customer testimonials consistently highlight machine longevity, consistent performance, and excellent after-sales support.

With exports spanning multiple continents, AmarPack demonstrates commitment to international quality standards and customer service. The company’s global presence reflects its capability to meet diverse market requirements while maintaining consistent quality across different operating environments. Export success validates the company’s technological competence and manufacturing excellence.

Founded in 1998 in Mumbai, India, AmarPack Machines Pvt. Ltd. is one of India’s leading manufacturers and exporters of premium packaging machines. Read More

GST No. 27AAZCA2345J1Z6

Get a quick quote from our experts. Fast response guaranteed!