In today’s competitive packaging industry, choosing the right sealing solution is critical for businesses aiming to improve packaging speed, maintain product freshness, and deliver a professional finish. Whether you’re in the food, pharmaceutical, chemical, or FMCG industry, investing in a reliable Band Sealing Machine can dramatically improve your packaging line’s efficiency, reduce labor costs, and enhance product presentation. However, with several models available—each designed for specific applications—how do you know which Band Sealer is ideal for your business?

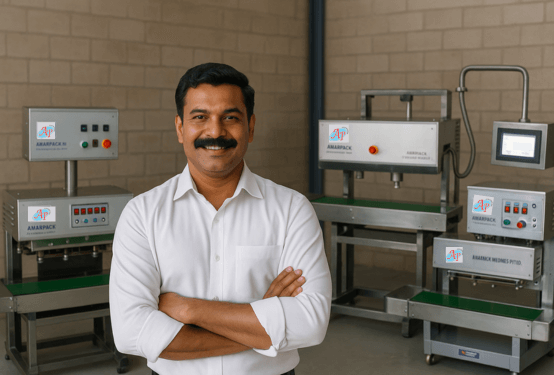

This detailed guide from AmarPack Machines Pvt Ltd, a leading manufacturer and exporter of packaging machines in India, breaks down each type of Continuous Band Sealing Machine and matches it with suitable product categories and industry applications. We also cover the benefits, ideal usage scenarios, and keyword-rich insights to help you make an informed decision and optimize your online searches.

Best Suited For: Lightweight pouches, small food packets, pharma sachets, spices, powders, and small-scale packaging lines.

Industries: FMCG, Confectionery, Spices & Masalas, Pharmaceutical, Nutraceutical

Why Choose the Mini Vertical Model?

Key Features:

Best Suited For: Heavier pouches, medium-to-large food packs, liquid sachets, detergent pouches, and oil packs.

Industries: Chemical, FMCG, Dairy, Lubricant, Agrochemical, Beverage

Why Choose the Master Vertical Model?

Key Features:

Best Suited For: Bakery items, namkeen, seeds, powder pouches, candies, medical kits.

Industries: Food & Snacks, Bakery, Agriculture, Healthcare, Cosmetics

Why Choose the Horizontal Mini Model?

Key Features:

Best Suited For: Bulk packaging of grains, pet food, hardware items, electronic components, fertilizers.

Industries: Agro Products, Electronics, Pet Food, Hardware, Industrial Supplies

Why Choose the Horizontal Master Model?

Key Features:

Best Suited For: Chips, dry fruits, snacks, spices, roasted snacks, powdered milk, protein supplements.

Industries: FMCG, Snack Foods, Health Foods, Spices & Condiments

Why Choose Nitrogen Flushing with Band Sealer?

Key Features:

Best Suited For: High-precision sealing of pharma products, medical kits, export-grade food pouches, and electronics.

Industries: Pharmaceuticals, Healthcare, Export Packaging, Electronics

Why Choose IPC-Based Band Sealer?

Key Features:

Best Suited For: Flammable chemical pouches, solvent-based products, explosive-grade items, pesticides.

Industries: Paints, Explosives, Chemicals, Petrochemicals, Pesticides

Why Choose FLP Band Sealer?

Key Features:

Choosing the right Band Sealing Machine depends on multiple factors such as product type (dry/wet/liquid), pouch weight, production volume, packaging material, and working environment (normal/hazardous). Investing in the correct model ensures:

Enhanced productivity

Minimal sealing defects

Long-term cost savings

Compliance with safety and hygiene regulations

At AmarPack Machines Pvt Ltd, our experts guide you through live trials, custom configurations, and post-sales support to make sure you pick the best machine for your needs. We provide vertical, horizontal, nitrogen flushing, IPC-based, and flameproof sealing systems—each engineered to meet distinct industry requirements.

Founded in 1998 in Mumbai, India, AmarPack Machines Pvt. Ltd. is one of India’s leading manufacturers and exporters of premium packaging machines. Read More

GST No. 27AAZCA2345J1Z6

Get a quick quote from our experts. Fast response guaranteed!