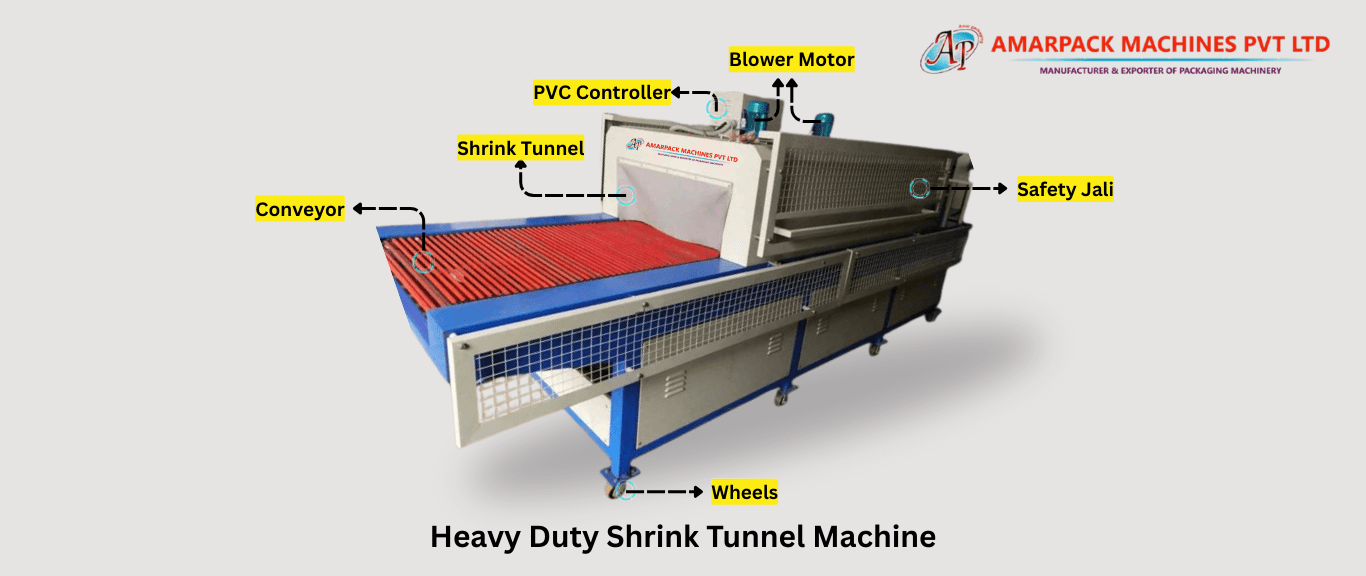

Shrink Tunnel Machine: Why Global Brands Prefer Made in India Solutions Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Type Rotary Type Automatic Type Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semiautomatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 Name Email Message Send India is rapidly emerging as a global manufacturing powerhouse—and the Shrink Tunnel Machine segment is no exception. With cutting-edge technology, competitive pricing, and unmatched customizability, Indian manufacturers are now the go-to choice for top brands worldwide. In this blog, we explore why global buyers consistently choose Made in India Shrink Tunnel Machines and how they outperform global alternatives. What Is a Shrink Tunnel Machine? A Shrink Tunnel Machine is a packaging machine used to shrink plastic film tightly around products. The heat from the tunnel ensures a secure, tamper-proof seal—making it ideal for packaging boxes, bottles, and consumer goods. It’s commonly used in industries like food & beverage, cosmetics, pharmaceuticals, and electronics. Why Are Indian Shrink Tunnel Machines Gaining Global Popularity? 1. High-Quality Engineering at Competitive Prices India combines skilled craftsmanship with the latest automation trends. This makes Indian Shrink Tunnel Machines cost-effective without compromising on performance or durability. 2. Customization for Every Industry From pharmaceuticals to FMCG, Indian manufacturers offer tailor-made shrink tunnel machines based on product size, heat levels, and conveyor speed—something international suppliers often lack. 3. Global Compliance and Standards Indian manufacturers are now ISO certified and offer machines that comply with CE and other global quality standards. This makes them reliable for export to the USA, UAE, Europe, and Africa. Benefits of Using a Shrink Tunnel Machine in Your Business Tamper-proof Packaging Increased Shelf Life Improved Product Presentation Reduced Packaging Cost Higher Production Speed Why Global Brands Trust AmarPack Machines Pvt Ltd With over two decades of experience, AmarPack Machines Pvt Ltd has become a trusted name among over 100 corporate clients including Colgate, Hindustan Unilever, and Cipla. Our Shrink Tunnel Machines are known for compact design, energy efficiency, and global export quality. We have served businesses in more than 15 countries including UAE, Italy, Nigeria, and Australia. Real-World Applications Across Industries Industry Application Food & Beverage Bottle shrink wraps, tray packs Pharma & Healthcare Tamper-evident medicine packs Cosmetics Compact sealing for boxed items Electronics Dust-proof packaging for gadgets Logistics & E-commerce Bulk shrink-wrapping for shipping https://youtu.be/WjlKkEO01Ps Key Features of AmarPack Shrink Tunnel Machines Adjustable heat controls Variable speed conveyor system Energy-efficient infrared heaters Compact and rugged design Easy integration with L-sealer or Web Sealer When quality, affordability, and international standards matter, Made in India Shrink Tunnel Machines rise above the competition. With global brands increasingly shifting to Indian suppliers, now is the right time to invest in a reliable, future-ready solution. Visit AmarPack’s Shrink Tunnel Machine Page Read: How Smart Packaging Machines Are Transforming the Future of Manufacturing and Logistics in India

Fully Automatic Leaflet Inserting and Bottle collecting wrapping machine

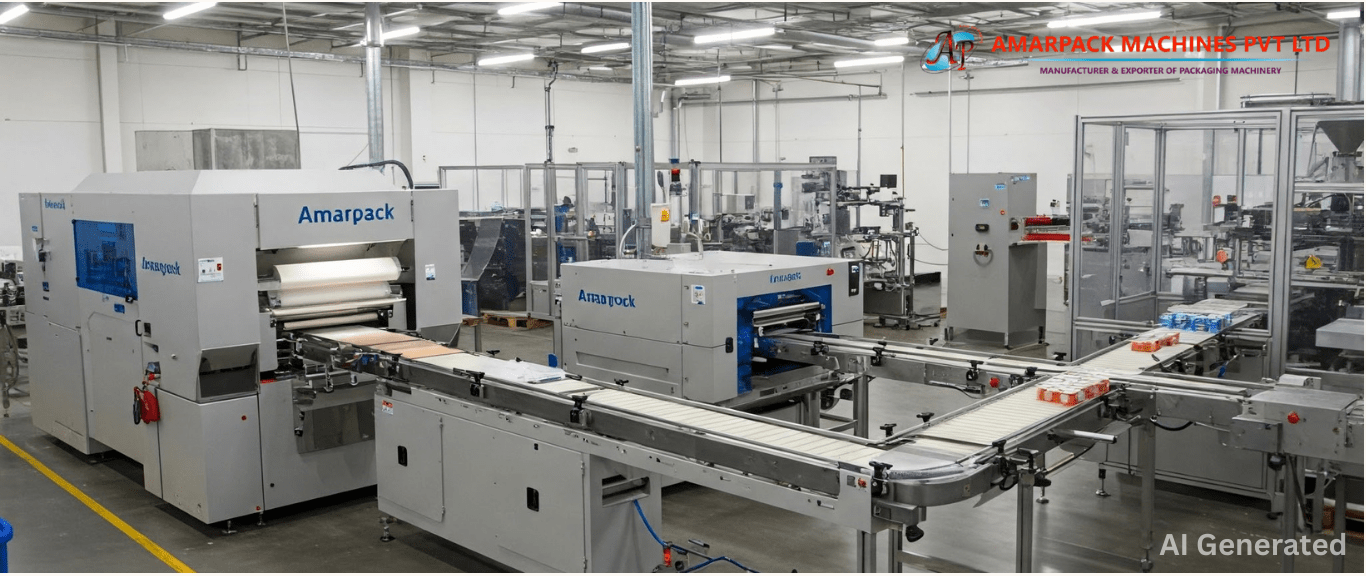

Fully Automatic Leaflet Inserting and Bottle collecting wrapping machine Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Type Rotary Type Automatic Type Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semiautomatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 📩Get Expert Advice or a Demo Today! Name Email Message Send AI Generated Image In today’s fast-paced manufacturing and packaging industry, efficiency and automation are paramount. Businesses are constantly seeking solutions that streamline their processes, reduce manual labor, and ensure consistent, high-quality output. The Fully Automatic Leaflet Inserting, Bottle Collecting & Wrapping Machine stands out as a versatile and powerful solution for various sectors. This comprehensive guide will delve into its features, working principles, benefits, and address frequently asked questions, all while highlighting its relevance for businesses in Mumbai and across India. Streamline Your Packaging: Unveiling the Power of Automatic Leaflet Inserting, Bottle Collecting & Wrapping Machines In the dynamic world of manufacturing and packaging, staying ahead means embracing efficiency and automation. If you’re looking to revolutionize your production line, particularly when it comes to handling bottles and accompanying leaflets, then the Fully Automatic Leaflet Inserting, Bottle Collecting & Wrapping Machine might just be the game-changer you’ve been searching for. Imagine a seamless process where leaflets are precisely placed with your bottles, the bottles are neatly grouped, and then securely wrapped – all without significant manual intervention. This isn’t a futuristic fantasy; it’s the reality offered by these sophisticated integrated systems. Whether you’re a burgeoning business in Mumbai or an established industry leader across India, understanding the capabilities of these machines is crucial for optimizing your operations. What Makes These Machines So Efficient? Key Features at a Glance These aren’t your run-of-the-mill machines. They’re packed with features designed for optimal performance: Blazing Fast Operation: Increased output means quicker turnaround times, a crucial advantage in today’s competitive market. Pinpoint Leaflet Placement: Ensure every customer receives the right information, presented professionally. Adaptable Bottle Handling: From sleek pharmaceutical vials to robust beverage containers, these machines can handle a variety of shapes and sizes. Customizable Wrapping: Tailor the wrapping style and tightness to meet your specific product needs. Intuitive Control: Easy-to-use interfaces minimize training time and simplify operation. Built to Last: Robust construction ensures years of reliable service, a smart investment for your business in India. Space-Saving Design: Maximize your operational area, especially important in space-constrained environments like many in Mumbai. Seamless Integration: Effortlessly connect with your existing bottling and packaging lines. Safety First: Integrated safety features protect your valuable workforce. Low Maintenance: Designed for minimal downtime, keeping your production running smoothly. Why Choose an Integrated System Over Separate Machines? It’s a valid question! Here’s a quick comparison: Feature Standalone Machines Integrated System Space Takes up more valuable floor space. Saves significant space. Efficiency Slower due to manual transfer between stages. Faster and more efficient with automated flow. Labor Requires more personnel for operation and transfer. Reduces labor costs significantly. Coordination Can be complex to synchronize different machines. Seamlessly coordinated operation. Cost (Long-Term) Potentially higher due to increased labor and space needs. Lower long-term operational costs. Consistency Higher chance of inconsistencies. Ensures uniform and consistent packaging. https://youtu.be/qibRioRDXO8 How Does the Magic Happen? A Simplified Workflow Curious about the process? Here’s a peek behind the curtain: Bottles Enter: Bottles flow into the machine, often directly from the filling stage. Leaflets Join the Party: Leaflets are automatically fed and precisely placed next to the bottles. Bottles Get Organized: The machine neatly groups the bottles according to

Why Double Chamber Vacuum Packaging Machines Are a Game-Changer for Bulk Packaging in 2025

Why Double Chamber Vacuum Packaging Machines Are a Game-Changer for Bulk Packaging in 2025 Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Type Rotary Type Automatic Type Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semiautomatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 📩Get Expert Advice or a Demo Today! Name Email Message Send AI Generated Image In the fast-paced world of manufacturing, packaging efficiency and product quality are paramount. The need for bulk packaging solutions that are both fast and reliable has never been greater. One packaging technology that is taking the industry by storm in 2025 is the Double Chamber Vacuum Packaging Machine. This advanced machine is revolutionizing how businesses package products in bulk, especially in sectors like food, pharmaceuticals, and FMCG (Fast-Moving Consumer Goods). Whether you’re in food processing, pharmaceuticals, or electronics, a Double Chamber Vacuum Packaging Machine could be the solution you’ve been looking for. Let’s dive into why this machine is a game-changer for bulk packaging in 2025, and how it can streamline your production processes. What is a Double Chamber Vacuum Packaging Machine? A Double Chamber Vacuum Packaging Machine is a high-efficiency packaging solution that uses two chambers to simultaneously seal products in vacuum-sealed bags. It works by removing the air from the packaging, ensuring that the product stays fresh and protected from external contaminants, such as oxygen and moisture. This is achieved in two chambers, which operate in tandem: while one chamber is sealing the product, the other is being loaded. This continuous operation maximizes efficiency, significantly reducing downtime. Why Double Chamber Vacuum Packaging Machines Are Essential for Bulk Packaging In 2025, speed and quality are more critical than ever. Businesses that deal with large volumes of products need packaging solutions that meet the demand for fast, consistent results. Here’s why Double Chamber Vacuum Packaging Machines are leading the way in bulk packaging: 1. Increased Packaging Speed The dual-chamber system allows for continuous operation, meaning that while one chamber is sealing, the other can be loaded. This results in higher throughput and minimizes the downtime typically associated with single-chamber systems. For manufacturers who need to process hundreds or thousands of units per day, this increase in efficiency is a game-changer. Pro Tip: By automating the bulk packaging process, you can drastically reduce labor costs and human error, making the overall process more reliable and cost-effective. 2. Extended Shelf Life and Improved Product Preservation One of the standout features of the Double Chamber Vacuum Packaging Machine is its ability to preserve the quality of the packaged product. Vacuum sealing removes oxygen, which slows down the growth of bacteria and molds. This preservation technology is particularly valuable in industries like food packaging, where extended shelf life can significantly reduce waste. Interesting Fact: Did you know that vacuum-sealed packaging can extend the shelf life of food by 2-3 times compared to traditional packaging methods? This makes it ideal for packaging fresh produce, meat, seafood, and even ready-to-eat meals. 3. High-Quality Seals for Maximum Product Protection When it comes to bulk packaging, seal integrity is non-negotiable. The Double Chamber Vacuum Packaging Machine ensures that every package is tightly sealed, protecting the product from contamination and external elements like moisture, dust, and air. This quality is critical for sensitive items, particularly in the pharmaceutical industry, where maintaining the integrity of medications is vital. Pro Tip: Ensure your machine has an adjustable sealing time and temperature control to achieve the perfect seal every time, regardless of the

Is a Nozzle Type Vacuum Packaging Machine Right for Your Business? A Complete Buyer’s Guide (2025 Edition)

Is a Nozzle Type Vacuum Packaging Machine Right for Your Business? A Complete Buyer’s Guide (2025 Edition) Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Type Rotary Type Automatic Type Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semiautomatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 📩Get Expert Advice or a Demo Today! Name Email Message Send Unlock Extended Shelf Life, Better Product Protection & Smarter Packaging Decisions AI Generated Image In today’s fast-paced manufacturing and export-driven industries, product shelf life, packaging hygiene, and moisture control are not just value-adds—they’re competitive necessities. Whether you’re in food processing, pharmaceuticals, electronics, or chemical manufacturing, choosing the right vacuum packaging solution directly impacts product quality, operational efficiency, and customer satisfaction. Among the most popular options, the Nozzle Type Vacuum Packaging Machine has become a top choice for businesses requiring flexible, efficient, and affordable vacuum sealing solutions. But is it the best fit for your business model? This comprehensive guide will help you evaluate its benefits, working process, industry use-cases, pros vs cons, and how it compares to other vacuum sealing technologies. What Is a Nozzle Type Vacuum Packaging Machine? A Nozzle Type Vacuum Packaging Machine uses a retractable stainless steel nozzle to extract air from the packaging bag externally. After vacuuming, the bag is tightly sealed using heat, protecting the contents from moisture, air, and contamination. Unlike chamber-type machines that enclose the bag entirely, nozzle types work outside the chamber, giving you greater flexibility in bag size and material. Top 6 Reasons Businesses Choose Nozzle Type Vacuum Packaging Machines 1. Versatile Packaging for Different Product Sizes From small sachets to large industrial pouches, nozzle-type machines handle a wide range of bag sizes. No need to worry about chamber limitations. 2. Compatible with Liquids and Semi-Liquids Thanks to precision vacuum control, this machine is ideal for sealing products like pickles, sauces, marinated meats, and chemicals—where chamber machines often struggle. 3. Compact, Space-Saving Design Unlike large chamber units, nozzle vacuum machines are table-top or mobile, making them perfect for space-conscious production floors. 4. Lower Operational Costs Because they don’t require a sealed chamber or heavy-duty infrastructure, maintenance and operational costs are lower—ideal for growing businesses. 5. Improved Shelf Life and Product Integrity Vacuum-sealed bags extend shelf life by preventing oxidation, mold growth, and spoilage, giving your brand a higher standard of quality. 6. Compliance with Export Standards Nozzle vacuum packaging ensures moisture-free and hygienic sealing, making it compliant with international food, pharma, and electronics packaging regulations. Industries That Benefit Most from Nozzle Type Vacuum Packaging Machines Industry Use Case Food & Beverage Meat, spices, grains, pickles, frozen items Pharma Bulk drugs, powders, medical kits Electronics Moisture-sensitive components and circuit boards Agriculture Seeds, fertilizers, organic produce Chemical Liquids, semi-liquids, pastes, and solvents Nozzle Type vs Chamber Type: Which One Wins for You? Vacuum Machine Comparison Feature Nozzle Type Machine Chamber Type Machine Bag Size Flexibility High – works with any size Limited to chamber dimensions Suitable for Liquids Yes (with controlled nozzle flow) Limited or risky without upgrades Speed of Operation Medium (ideal for semi-auto setups) Fast (bulk processing) Initial Cost Lower Higher Maintenance Complexity Low Moderate Ideal For Diverse, non-uniform product lines Uniform, high-volume production What to Look for When Buying a Nozzle Type Vacuum Packaging Machine (2025 Checklist) Before making your investment, ensure the machine offers the following features: ✔️ Adjustable vacuum and sealing time ✔️ High suction capacity (250–500 L/min) ✔️ Food-grade stainless steel construction (SS304/SS316) ✔️ Digital control panel with

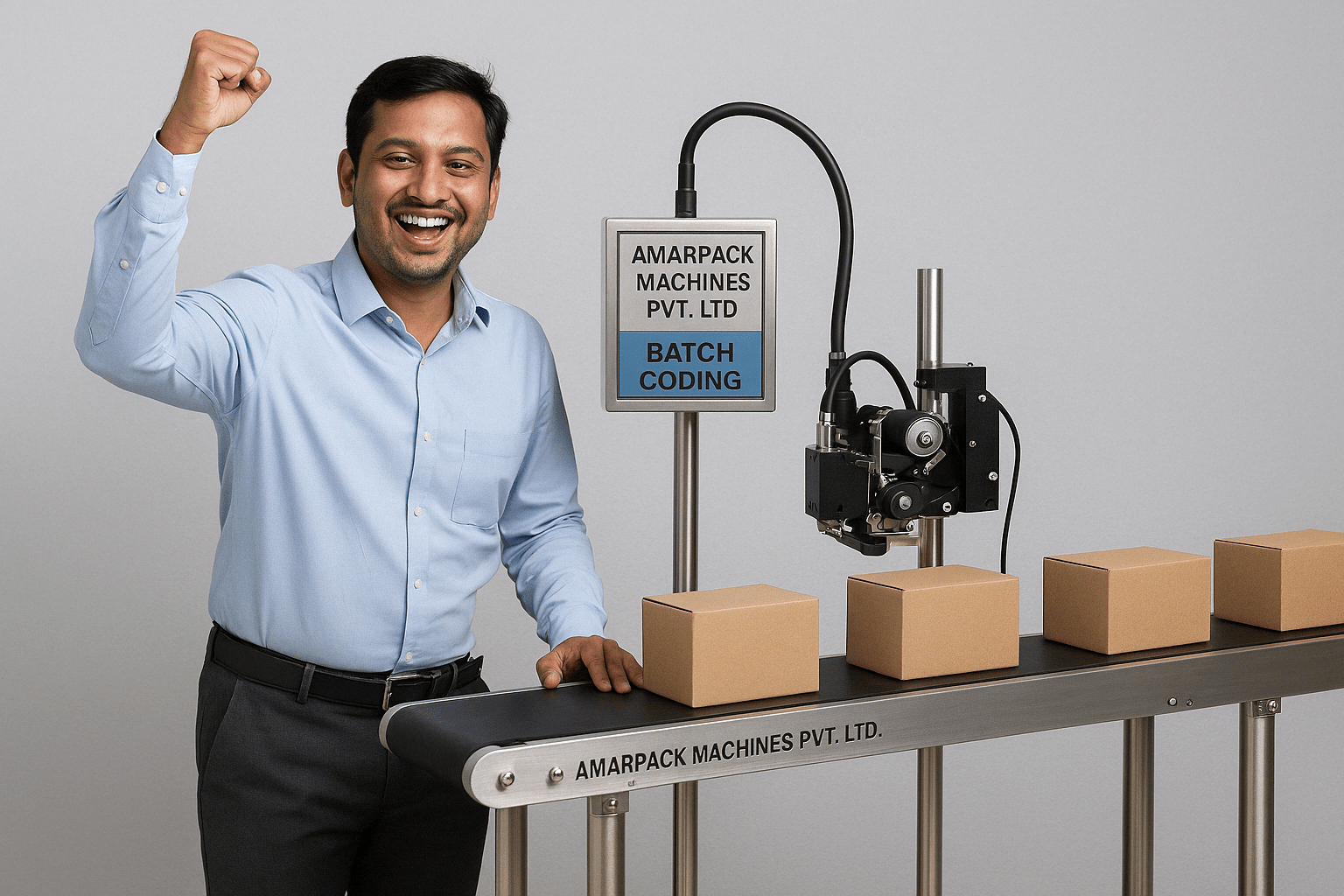

How Adding a Conveyor to Your Batch Coding Machine Boosts Efficiency and Quality

How Adding a Conveyor to Your Batch Coding Machine Boosts Efficiency and Quality Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Type Rotary Type Automatic Type Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semiautomatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 Name Email Message Send AI Generated Image In today’s fast-paced manufacturing environment, maximizing efficiency, minimizing errors, and maintaining high standards of product quality are top priorities for business owners. One of the best ways to achieve this is by integrating a conveyor system with your batch coding machine. While a batch coding machine is essential for marking products with critical information like expiration dates, lot numbers, and barcodes, a conveyor system brings added automation that transforms how you approach production. In this blog, we’ll dive deep into how this integration can revolutionize your production line, reduce costs, and improve both speed and accuracy. Let’s explore the top benefits of adding a conveyor to your batch coding machine, especially from the perspective of manufacturers and business owners looking to stay ahead in the competitive market. 1. Increased Productivity with Continuous Flow One of the primary benefits of adding a conveyor to your batch coding machine is the boost in productivity. Automation in production lines allows products to flow continuously from one station to the next, reducing time-consuming manual interventions. Here’s how it benefits your workflow: Seamless Transport: With a conveyor system, products are automatically delivered to the batch coding machine without human intervention, ensuring that your coding process never stops. Faster Throughput: As products move through the system without delay, batch coding machines can operate at their optimal speed, resulting in faster output and reduced processing time. This continuous flow not only maximizes production capacity but also supports high-volume production runs, essential for businesses aiming to meet increasing demand without compromising on product quality. 2. Reduced Human Error in Product Marking Manual labor in product coding often leads to inconsistencies, errors, or misplaced labels, which can be costly. By integrating a conveyor with your batch coding machine, you can significantly reduce these risks: Precise Alignment: The conveyor system ensures products are consistently aligned for precise coding, eliminating misalignment errors that can occur in manual processes. Automated Handling: With automated product handling, the risk of human mistakes like wrong placements or overlooked product markings is minimized, resulting in consistent quality across all batches. In regulated industries like pharmaceuticals, food packaging, and cosmetics, where accuracy is non-negotiable, this reduction in human error helps businesses maintain high standards and comply with strict regulatory requirements. 3. Enhanced Product Traceability and Compliance For businesses in sectors where traceability is paramount, such as pharmaceuticals, food & beverage, and cosmetics, having a reliable system to track products is crucial. A batch coding machine with a conveyor system significantly improves product traceability: Real-Time Coding: As products pass through the conveyor, they are automatically coded with batch numbers, expiration dates, and other essential details, providing an up-to-date record for each product. Seamless Integration: The integration ensures that each product is marked consistently, creating a traceable path from the start of the production line to the end. This audit trail is vital for compliance with FDA guidelines, ISO standards, and GMP regulations. With automated traceability, your business can easily meet compliance standards and maintain an efficient product recall process in case of any safety issues, safeguarding both your reputation and bottom line. 4. Scalability and Flexibility for Growing Businesses As your business expands, your production line must

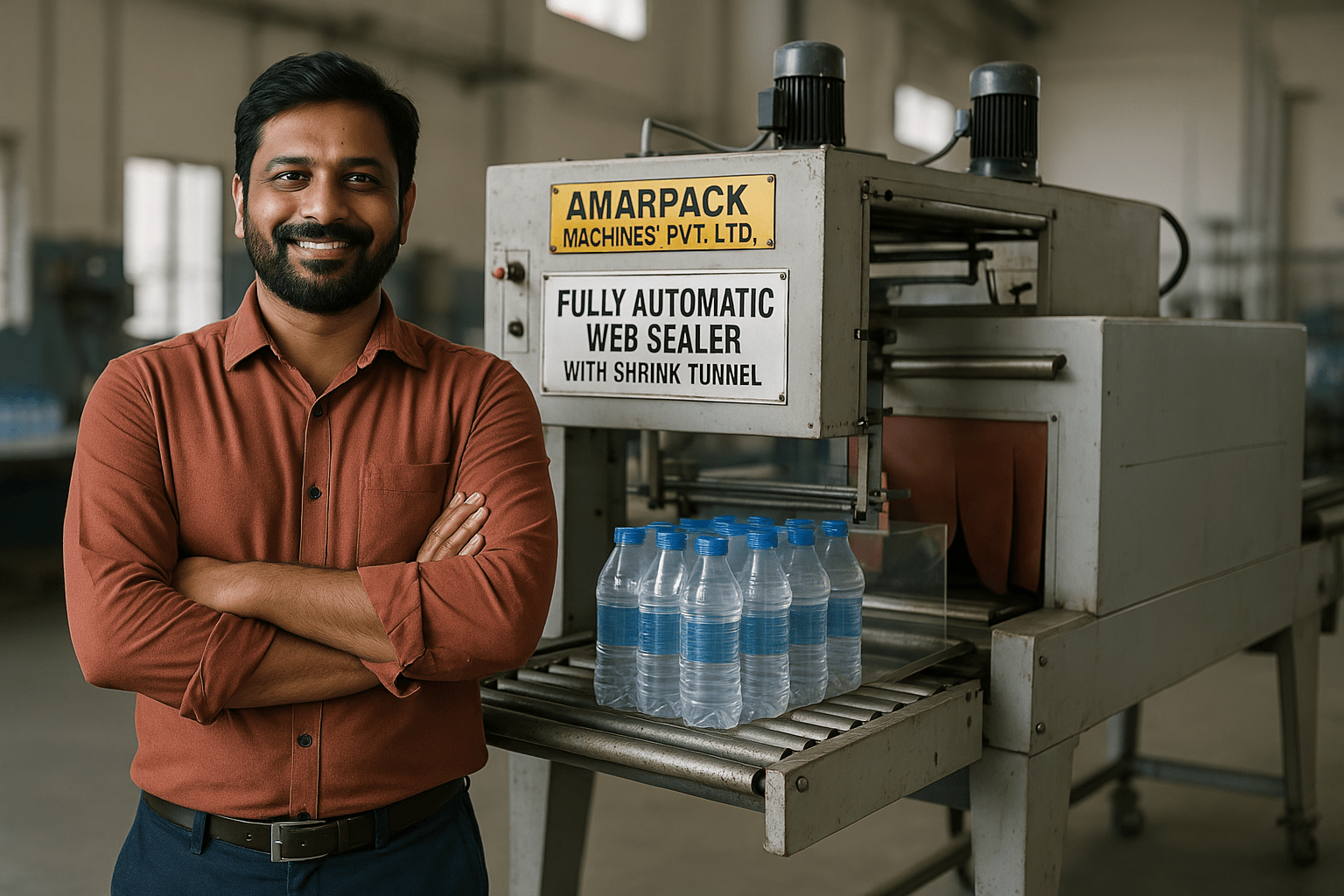

Automatic Web Sealer with Shrink Tunnel vs. Manual Bottle Packing – Which One Wins in 2025?

Automatic Web Sealer with Shrink Tunnel vs. Manual Bottle Packing – Which One Wins in 2025? Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Type Rotary Type Automatic Type Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semiautomatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 Name Email Message Send AI Generated Image In 2025, the packaging industry is undergoing a transformative shift—one where speed, consistency, cost-efficiency, and automation are no longer luxuries but necessities. For businesses dealing with bottled products like cold drinks, mineral water, juices, edible oils, lubricants, or even pharma items, the debate between Manual Bottle Packing, Semi-Automatic Web Sealer with Shrink Tunnel Machines, and Fully Automatic Web Sealer with Shrink Tunnel Machines is more relevant than ever. This blog is your definitive guide to understanding which type of bottle packaging method is best suited for your business. We will break down the differences in technology, speed, costs, quality, scalability, and applications—so you walk away fully informed. Manual vs Semi-Automatic vs Fully Automatic Bottle Packaging – What’s the Core Difference? Let’s begin with a breakdown: Manual Bottle Packing: Entirely dependent on human labor. Bottles are grouped, wrapped, sealed, and packed manually using heat guns or hand sealers. Semi-Automatic Web Sealer with Shrink Tunnel: Bottles are manually loaded onto the conveyor, but sealing and shrink wrapping are automated. Fully Automatic Web Sealer with Shrink Tunnel Machine: Complete automation—from feeding bottles, aligning them, sealing, cutting the shrink film, and passing through the shrink tunnel without any manual handling. Which to Choose? For startups or very low volume: Manual For mid-scale businesses with growing demand: Semi-automatic For large-scale production with 24×7 operations: Fully automatic Packaging Speed & Efficiency – Go Automatic for Volume If you’re dealing with thousands of bottles per day, manual methods will choke your throughput. Even semi-automatic systems, though efficient, rely on human loading/unloading, which causes bottlenecks. Automatic Web Sealer with Shrink Tunnel Machines deliver consistent high-speed output. Paired with infeed and outfeed conveyors, they can handle up to 20–30 packs per minute depending on bottle size and layout. Pro Insight: A fully automatic shrink packaging line reduces average packaging time per bottle by over 60% compared to semi-automatic systems. Quality and Consistency – Eliminate Human Errors Manual sealing often results in loose wraps, air bubbles, misaligned groups, and film burns. Even semi-automatic machines can vary in output depending on how operators load the product. Fully Automatic Web Sealer with Shrink Tunnel Machines ensure: Uniform sealing pressure Precise cutting of shrink film Exact alignment of grouped bottles A smooth, wrinkle-free shrink finish This is critical for premium products like cold drinks, branded bottled water, or cosmetic bottles where shelf appeal matters. Film Optimization – Reduce Waste and Save Cost Shrink film is one of the most expensive consumables in packaging. Manual and semi-automatic operations often lead to film wastage due to inconsistent sizing or improper sealing. Fully Automatic Machines have sensors and servo systems that cut the film exactly based on the product’s dimensions. This ensures: Up to 25% savings in shrink film consumption Lower overall cost per pack More eco-friendly operations Bonus: Many automatic machines offer adjustable settings for varying bottle sizes in one line. Scaling Up – Future-Proofing Your Packaging Line If you have plans to grow your business, your packaging system should scale with you. Manual systems are non-scalable. Semi-automatic machines scale only slightly and require more labor as volume grows. Fully automatic systems can be upgraded with: Multi-lane conveyors Robotic pick-and-place systems

Boost Pharma Efficiency with a Fully Automatic Eye Drop Filling, Capping & Sealing Machine

Boost Pharma Efficiency with a Fully Automatic Eye Drop Filling, Capping & Sealing Machine Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Type Rotary Type Automatic Type Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semiautomatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 Name Email Message Send AI Generated Image Why Today’s Pharma Leaders Are Automating In pharmaceutical manufacturing, every second counts. Whether you’re producing for domestic demand or competing in global markets, speed, precision, and compliance drive success. If your eye drop packaging line still involves manual or semi-automatic processes, you’re likely battling: Slow output Quality inconsistencies Labor challenges Regulatory risks This is where a Fully Automatic Eye Drop Filling, Capping & Sealing Machine becomes more than equipment—it becomes your competitive advantage. 1. Multiply Your Production Output—Without Adding Labor With automation, businesses are scaling faster, fulfilling larger orders, and reducing delivery timelines. This machine can handle up to 120 bottles per minute, with synchronized filling, capping, and sealing. Real Business Gains: Finish orders in 1/3rd the time Meet export-level volume demands Run 24/7 production with minimal manpower For pharma brands looking to expand or fulfill high-demand contracts, this is a breakthrough in productivity. 2. Eliminate Human Error & Ensure Regulatory Compliance In pharma, the margin for error is zero. One minor contamination or underfilled bottle could lead to serious repercussions. The machine ensures: GMP-compliant operations Sterile filling under laminar flow No-touch capping and sealing What That Means for You: Cleaner, safer, and fully compliant batches Less risk of rejection from QC departments or export audits Stronger trust from doctors, distributors, and end users 3. Reduce Operational Costs Over Time Let’s talk ROI. Switching to a fully automatic system may seem like a capital expense upfront—but it pays back quickly by cutting costs in: Manual labor Product wastage Machine downtime You save on salaries, training, supervision, and error correction. Over 6–12 months, the machine starts paying for itself. 4. Compact Eye Drop Filling Machine for Any Pharma Production Setup Think automation needs massive space? Think again. This machine is designed for: Small-to-mid pharma units Contract manufacturing facilities Companies looking to scale without expanding infrastructure Its modular design can be easily integrated into your existing layout, whether you’re working in a sterile clean room or a compact packaging zone. 5. One Machine. Full Control. Seamless Operation. Today’s production leaders don’t just want speed—they want control. This machine is equipped with: PLC-based operation Touchscreen HMI Real-time data monitoring Automatic rejection of faulty units You know exactly what’s happening at every stage—no guesswork, no downtime surprises. Scaling Production with a Fully Automatic Eye Drop Packaging Machine A pharma company in Mumbai faced delays in fulfilling export orders due to outdated semi-automatic lines. After switching to AmarPack’s fully automatic eye drop filling line: Production speed increased by 3X Labor costs dropped by 38% Compliance passed EU inspection without a single deviation https://youtu.be/-C3bczoBwp0?si=G2nsQJ1KXgTtmZYC This Is Not Just an Upgrade—It’s a Business Move In pharma, you can’t afford to fall behind.A Fully Automatic Eye Drop Filling, Capping & Sealing Machine isn’t just about faster production—it’s about future-proofing your operations, delivering consistent quality, and competing with confidence in a regulated, high-demand market. AmarPack Machines Pvt Ltd offers pharma-grade packaging solutions trusted by global clients. Customized integration Installation & training support Fast after-sales service Export-ready build quality Recommended Reading: How Smart Packaging Machines Are Transforming the Future of Manufacturing and Logistics in India

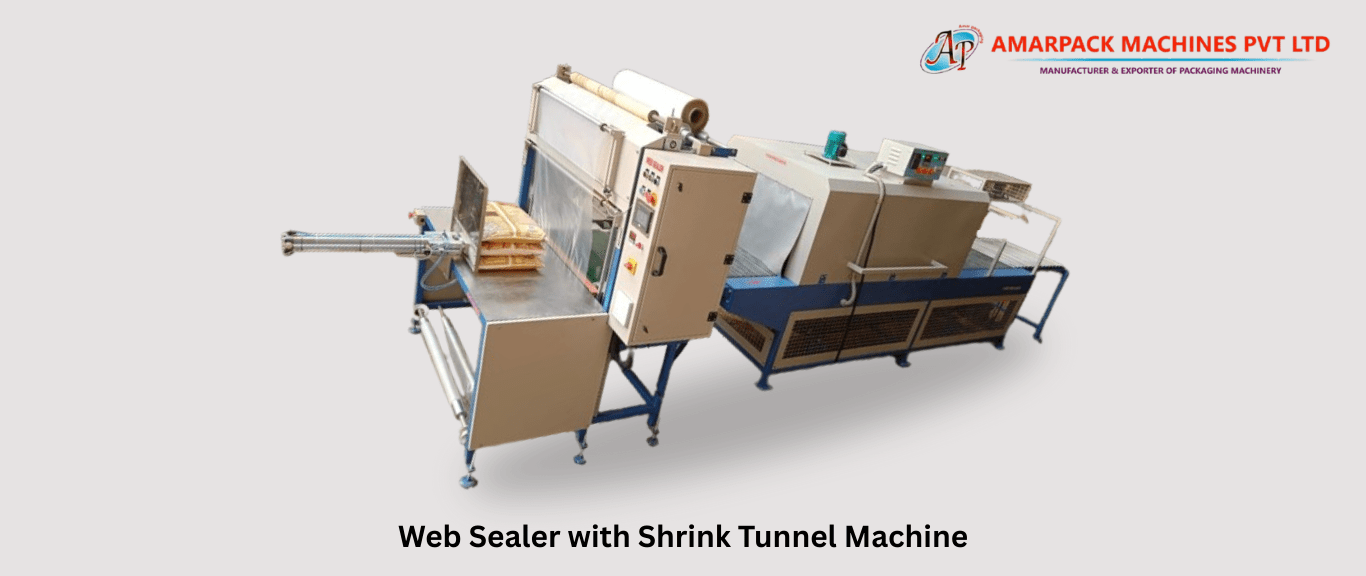

Web Sealer with Shrink Tunnel Machine: The Ultimate Solution for Bulk Packaging

Web Sealer with Shrink Tunnel Machine: The Ultimate Solution for Bulk Packaging Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Type Rotary Type Automatic Type Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semiautomatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 Name Email Message Send Imagine running a fast-paced factory where hundreds — maybe thousands — of products need to be packed every hour. You’re dealing with rising labor costs, packaging inconsistencies, and production delays. Sounds familiar? Now imagine a solution that handles your bulk packaging flawlessly, wraps each product with precision, and seals it securely — all at high speed, all in one go. Introducing the Web Sealer with Shrink Tunnel Machine — a powerhouse that’s transforming packaging lines across India and beyond. The Real Packaging Problem (And Why You Might Be Facing It) Bulk packaging isn’t as easy as it looks. Whether you’re packing flour bags, bottled beverages, cartons, or retail trays, you’ve probably faced challenges like: Torn or weak packaging due to manual errors Unattractive final packaging that fails to impress on shelves Wasted time and labor due to slow sealing processes Products damaged during transport because they weren’t tightly packed These aren’t small problems — they cost time, money, and sometimes even clients. The Web Sealer with Shrink Tunnel Machine: What Makes It So Powerful? This machine combines speed, strength, and simplicity. Here’s how it works (without the jargon): Your product enters the machine on a conveyor. The web sealer wraps it with shrink film from both sides and seals it. The sealed package passes into the shrink tunnel, where hot air evenly shrinks the film around the product. Result? A tight, secure, professional-looking package that’s ready to ship or display. No rework. No double-checks. Just clean, consistent output. A Real Story: Flour Packaging That Changed Everything Let’s move from theory to the real world. One of our clients, a well-known flour (atta) manufacturer in Indore, came to us with a clear problem: “We’re growing fast — but our packaging process is holding us back.” They were packing 5kg flour pouches manually, sealing them with handheld sealers, and stacking them into boxes. Not only was this slow and labor-intensive, but the results were inconsistent. The final packaging didn’t reflect the quality of the product inside. We installed our Web Sealer with Shrink Tunnel Machine, and within days, their workflow completely changed: ✔️ Packing time reduced by over 50% ✔️ Final product looked cleaner and more retail-ready ✔️ No more film wastage or bad seals ✔️ The client now saves on labor while delivering premium-looking packaging They even allowed us to shoot a live demo video of the machine running at their plant — scroll down to watch it and see the transformation for yourself. https://youtu.be/JSu15aaD-Ys?si=jNSelyl0120R-BcJ 🗣️ Client Testimonial “We’ve cut our daily packing time by nearly half. The finish is clean, professional, and way more consistent than manual work. Our dispatch team is finally stress-free.”— Mr. Sharma, Owner, Flour Mill, Nepal Why This Machine is a Must for Bulk Packaging Operations Let’s break down the real benefits: Handles Large Volumes Like a Pro: Designed for non-stop operations Works with Heavy & Odd-Shaped Products: From flour bags to bottle trays Saves Film, Saves Money: Smart film-cutting with minimal waste Reduces Manual Labor: Automation takes over repetitive tasks Adds Shelf Appeal: Your packaging looks clean, tight, and professional Built for Tough Conditions: Rugged design with easy controls Whether you’re in food, beverages, cosmetics, pharmaceuticals, or logistics

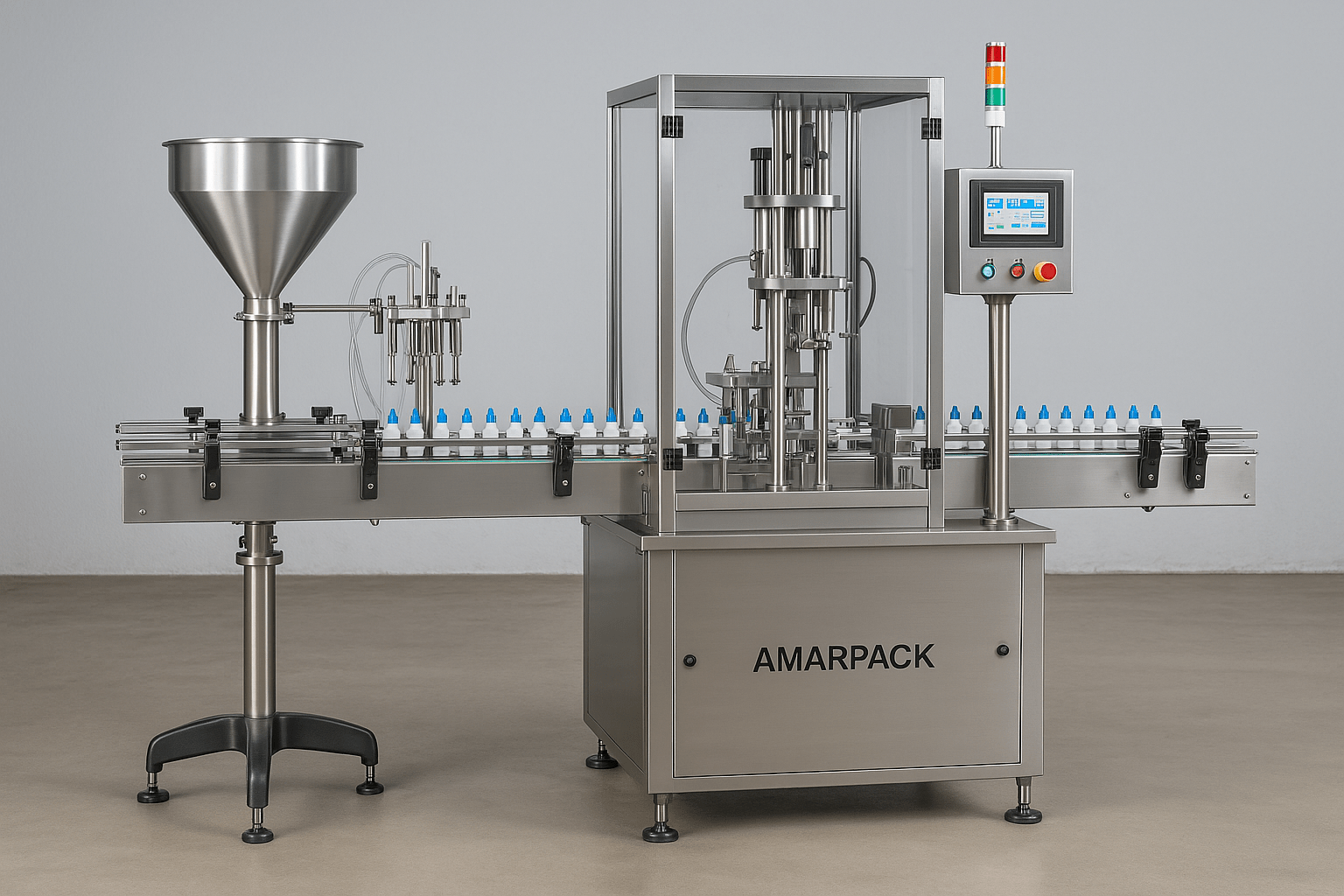

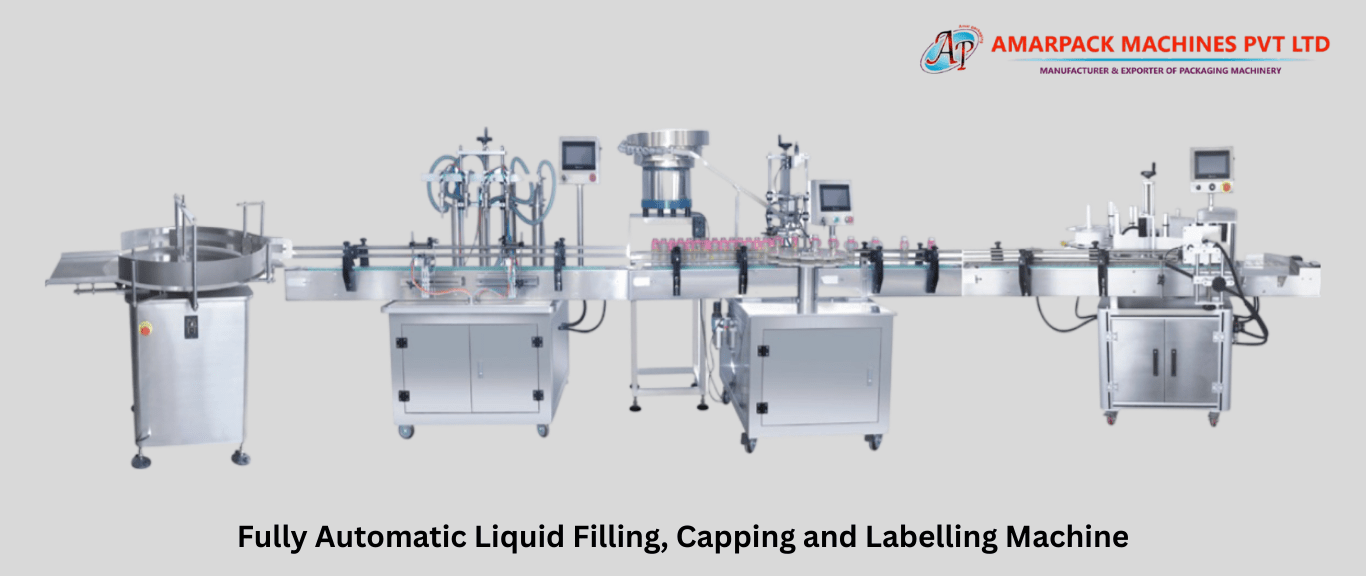

Boost Your Production with Fully Automatic Liquid Filling Machines by AmarPack Packaging Pvt. Ltd.

Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machines Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Type Rotary Type Automatic Type Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semiautomatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Humberger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio Mira Road (E) 401107 Name Email Message Send Boost Your Production with Fully Automatic Liquid Filling Machines by AmarPack Machines Pvt. Ltd. In the competitive world of manufacturing, where speed, precision, and cost-efficiency are key to success, having the right machinery is critical. Whether you’re manufacturing pharmaceutical products, food & beverages, cosmetics, or chemicals, the liquid filling process plays a central role in determining your production output and product quality. AmarPack Machines Pvt. Ltd. brings you cutting-edge fully automatic liquid filling machines designed to meet the diverse needs of industries across India and the globe. Our advanced technology ensures high precision, minimal wastage, and maximum efficiency on your production line. What is a Fully Automatic Liquid Filling Machine? A fully automatic liquid filling machine is a piece of automated equipment used in the packaging industry to fill bottles, jars, or other containers with liquids. Unlike semi-automatic machines, fully automated systems do not require manual operation, making them ideal for high-volume, high-speed production lines. At AmarPack Machines Pvt. Ltd., our machines are designed to handle a wide range of liquids including water, oils, syrups, lotions, and even more viscous substances like creams and gels. Our liquid filling systems are known for their speed, accuracy, and ease of use, helping businesses optimize their packaging processes while reducing labor costs and production time. Key Benefits of Fully Automatic Liquid Filling Machines Increased Efficiency & Speed: High-speed filling processes that allow for increased production and shorter turnaround times. Precise Volume Control: Accurate dosing ensures that each container receives the right amount of product, minimizing waste and improving quality control. Customizable: AmarPack’s machines are adaptable to various container sizes and liquid viscosities, making them suitable for a wide range of industries. Hygienic Design: Our machines comply with international hygiene standards (GMP) and are designed with Clean-in-Place (CIP) systems for easy cleaning between production runs. Durability & Reliability: AmarPack machines are built with the highest quality materials to ensure longevity and reduce downtime. Why Choose AmarPack Machines Pvt. Ltd. for Liquid Filling Machines? When looking for a liquid filling machine manufacturer, quality, reliability, and customer support are crucial. Here’s why AmarPack Machines Pvt. Ltd. stands out: 🌟 Tailored Solutions: Our fully automatic liquid filling machines can be customized to meet the unique needs of your production line. Whether you need specialized filling systems for pharmaceuticals, cosmetics, or beverages, we can design a solution that fits your requirements. 🛠️ Innovation at its Core: AmarPack invests heavily in research and development, ensuring that we stay ahead of the curve with the latest technology. Our machines incorporate servo motors, precision nozzles, and automatic changeover systems to minimize downtime and improve production efficiency. 🌍 Global Reach: With a proven track record across India and international markets, AmarPack has earned the trust of leading manufacturers and producers worldwide. 🏆 ISO-Certified Manufacturing: Our products are manufactured under stringent quality control processes in an ISO-certified facility, ensuring that every machine meets global standards for performance and reliability. ⚙️ End-to-End Support: From consultation to installation and maintenance, AmarPack provides comprehensive support throughout the life cycle of your filling machine. Applications of Fully Automatic Liquid Filling Machines The versatility of fully automatic liquid filling machines makes them suitable for a wide variety of industries. Some of the most common applications include: Pharmaceutical Industry Fully automatic liquid filling machines are essential in

How Smart Packaging Machines Are Transforming the Future of Manufacturing and Logistics in India

Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machines Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Type Rotary Type Automatic Type Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semiautomatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Humberger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio Mira Road (E) 401107 Name Email Message Send How Smart Packaging Machines Are Transforming the Future of Manufacturing and Logistics in India India’s manufacturing and logistics sectors are undergoing a significant transformation fueled by automation and smart packaging technology. As global demand intensifies and efficiency becomes critical, businesses are increasingly turning to advanced solutions that streamline operations, minimize errors, and enhance productivity. Among these innovations, smart packaging machines are redefining how products are packed, protected, and shipped with unmatched speed, precision, and durability. WHAT ARE SMART PACKAGING MACHINES? Smart packaging machines are automated systems engineered to perform complex packaging tasks with minimal human input. Equipped with cutting-edge features like PLC control systems, photoelectric sensors, adjustable speed settings, and integrated conveyor systems, these machines deliver consistent and efficient performance. Unlike traditional manual packaging, smart machines operate continuously and with precision, reducing waste and human error. KEY BENEFITS OF SMART PACKAGING TECHNOLOGY Enhanced Efficiency: High-speed operation enables the handling of large volumes with accuracy. Reduced Labor Costs: Automation significantly cuts down on manual workforce requirements. Improved Safety: Built-in sensors and protective systems reduce workplace hazards. Consistent Packaging Quality: Every package is sealed with precision, ideal for retail and export standards. Seamless Integration: These machines can be synchronized with other production systems for a streamlined workflow. INDUSTRY APPLICATIONS OF SMART PACKAGING MACHINES Smart packaging solutions are being adopted across various sectors, including: FMCG: For rapid sealing and shrink-wrapping of bottles, cartons, and snack items. Pharmaceuticals: In vacuum sealing and blister packing of sensitive medical supplies. eCommerce & Retail: For shrink-wrapping and protective box packaging of goods for safe transit. FEATURED MACHINE: AUTOMATIC WEB SEALER WITH SHRINK TUNNEL A top innovation from AmarPack Machines Pvt Ltd is the automatic web sealer with a shrink machine. Tunnel machine. Specially crafted for sealing and shrink-wrapping corrugated boxes and cartons, this fully automatic unit integrates a heavy-duty shrink tunnel, conveyor system, and photoelectric sensors. It delivers professional-grade results and is ideal for businesses aiming to upgrade their packaging lines with precision and reliability. AmarPack’s Automatic Web Sealer with Shrink Tunnel is ideal for bulk box packaging. Key Advantages: Efficiently handles bulk packaging Greatly reduces manual labor Provides faster, high-quality output Ensures neat and secure packaging for storage, shipping, and retail WHY NOW IS THE RIGHT TIME TO UPGRADE With the Indian government promoting smart manufacturing under the Make in India initiative and a rising emphasis on export quality, now is the ideal time to invest in smart packaging machines. Businesses adopting automation today will gain a strong competitive edge in both domestic and international markets. Smart packaging machines are no longer optional—they’re essential for modern businesses aiming to scale efficiently. AmarPack Machines Pvt Ltd proudly leads this evolution, providing high-performance, reliable, and future-ready packaging solutions. Upgrade now and stay ahead in the ever-evolving world of manufacturing and logistics. Stay connected with us! Follow, like & share for the latest updates on packaging solutions. Facebook Youtube Whatsapp Instagram