Why Heavy Duty Strapping Machines Are a Game-Changer for Industrial Packaging Product menu Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic Web Sealer with Shrink Tunnel (Bottle) Continuous Band sealing Machine Vertical continuous Band Sealer (Mini) Continuous Band Sealer Horizontal Master Model Horizontal Mini Model Vertical continuous band sealer (Master Model) Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L sealer with shrink tunnel machine Online L-Sealer Machine with shrink tunnel machine Pneumatic L-sealer with Shrink Tunnel Machine Fully Automatic L-Sealer with Shrink Tunnel Machine Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Tong sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyor Gravity Roller Conveyor Line shaft Roller Conveyor Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Sleeve Shrink Wrapping Rotary Type Sleeve Shrink Wrapping Machine Automatic Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semi-Automatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semi-Automatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 Name Email Message Send AmarPack MAchines Pvt Ltd In the fast-paced world of industrial packaging, speed, strength, and efficiency are not just desired—they are essential. From securing massive pallets and cartons to bundling bulky construction materials, a Heavy Duty Strapping Machine becomes a cornerstone of streamlined, secure, and cost-effective packaging. If your operations involve heavy loads, high throughput, or large-scale shipping, it’s time to discover how the right strapping solution can dramatically improve your packaging workflow. This guide will walk you through the key features, benefits, and applications of heavy duty strapping machines—and why companies across India and the globe trust AmarPack Machines Pvt Ltd for their packaging needs. What Is a Heavy Duty Strapping Machine? A heavy duty strapping machine is an industrial-grade packaging tool engineered to apply high-tension straps (usually PP or PET) around heavy or bulky loads. Designed for high-volume operations, these machines are built to work consistently in demanding conditions and are ideal for stabilizing items for storage or transport. Unlike manual or semi-automatic banding tools, these machines offer: Precision tension control High-speed strapping cycles Consistent performance Reduced manual labor They are available in automatic and semi-automatic configurations, offering solutions that fit both medium and large-scale packaging requirements. Key Features of a Heavy Duty Strapping Machine When investing in a strapping solution, it’s essential to look beyond just price. Here’s what makes heavy duty models a smart long-term investment: High Tensile Strength Support: Handles PP or PET straps from 12mm to 19mm. Automatic or Semi-Automatic Operation: Select based on your volume and workforce. Adjustable Tension Control: Ideal for delicate to rugged items. Durable Metal Build: Designed for long operational life in industrial settings. Fast Strapping Cycle: Typically 1.5–2.5 seconds per cycle. Low Maintenance: Fewer breakdowns, minimal servicing needs. Customizable Frame Sizes: Fits a variety of product dimensions. Benefits of Using a Heavy Duty Strapping Machine Enhanched Load Security Prevent product shifting, toppling, or damage during transit by applying the right strap tension. High-Speed Operations Strap hundreds of cartons, pallets, or containers per hour, drastically improving your dispatch efficiency. Reduced Labor Costs Automated processes mean fewer workers required for repetitive tasks. Minimal Downtime Built for rugged environments, these machines offer dependable 24/7 performance. Precision Tensioning Apply just the right amount of force—critical for both safety and product integrity. Feature Specification Strap Width 12mm – 19mm Strap Type PP / PET Tension Strength Up to 70 kg Power Supply 220V / 50Hz Cycle Time 1.5 – 2.5 seconds per strap Machine Type Automatic / Semi-Automatic Frame Size Customizable as per client need See the Working of Strapping Machine Why Buy from AmarPack Machines Pvt Ltd? AmarPack Machines Pvt Ltd is a leading manufacturer and exporter of shrink packaging machines in India. Whether you’re looking for a compact shrink chamber or a high-efficiency shrink tunnel machine, we provide tailored solutions for your industry needs. Our Strengths: 25+ years of experience in packaging machinery Custom solutions for shrink wrapping needs CE-certified machines with warranty and support Wide export network including USA, UAE, Africa,

Is a Semi-Automatic Shrink Chamber Machine Right for Your Business? Buyer-Focused Guide

Is a Semi-Automatic Shrink Chamber Machine Right for Your Business? Buyer-Focused Guide Product menu Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic Web Sealer with Shrink Tunnel (Bottle) Continuous Band sealing Machine Vertical continuous Band Sealer (Mini) Continuous Band Sealer Horizontal Master Model Horizontal Mini Model Vertical continuous band sealer (Master Model) Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L sealer with shrink tunnel machine Online L-Sealer Machine with shrink tunnel machine Pneumatic L-sealer with Shrink Tunnel Machine Fully Automatic L-Sealer with Shrink Tunnel Machine Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Tong sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyor Gravity Roller Conveyor Line shaft Roller Conveyor Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Sleeve Shrink Wrapping Rotary Type Sleeve Shrink Wrapping Machine Automatic Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semi-Automatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semi-Automatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 Name Email Message Send AI Generated If you’re a business owner exploring efficient and affordable packaging solutions, the Semi-Automatic Shrink Chamber Machine might already be on your radar. But how do you know if it’s the right investment for your packaging line? This comprehensive, keyword-rich buyer’s guide answers common questions and concerns from the point of view of a buyer, helping you make an informed decision. What Is a Semi-Automatic Shrink Chamber Machine? A Semi-Automatic Shrink Chamber Machine is a packaging system that integrates both sealing and shrinking into one compact unit. It utilizes a heating element to shrink plastic film around the product, ensuring a tight, tamper-proof wrap. The machine is designed for manual placement of products into the film sleeve, after which the chamber hood is pulled down. The machine then performs both sealing and shrinking, offering an efficient, semi-automated solution for low to medium-volume packaging operations. These machines are especially suitable for operations that don’t require fully automated systems but still need efficiency, professionalism, and safety in their packaging. Common materials used with this system include PVC shrink film, POF shrink film, and polyolefin shrink wrap, each chosen based on product type and required presentation. Who Should Buy a Semi-Automatic Shrink Chamber Machine? Ideal Business Types: Small and Medium Enterprises (SMEs): These businesses usually work on tighter budgets and have controlled production volumes, making this machine ideal for consistent, cost-efficient output. Startups: Particularly in industries like cosmetics, food, and herbal products, where attractive packaging plays a big role in brand perception. Food and Beverage Manufacturers: For packing items like bakery products, chocolates, juices, and ready-to-eat meals. Cosmetics and Personal Care Brands: Aesthetics are critical here, and a shrink chamber ensures clean, tamper-proof packaging. Pharmaceutical and Medical Supply Distributors: The need for hygienic, protective packaging is fulfilled perfectly with this machine. Stationery, Toys, and Gift Packaging Businesses: Great for wrapping gift sets, stationery bundles, and retail-ready packages. Benefits of Using a Semi-Automatic Shrink Chamber Machine Enhanced Product Presentation – Clean, professional, tamper-evident packaging Increased Shelf Life – Protects products from dust, moisture, and handling Improved Operational Efficiency – Sealing and shrinking in one step Compact Footprint – Easy to fit in small production units or workshops Low Operational Cost – Suitable for businesses with tight budgets Semi-Automatic vs. Fully Automatic Shrink Wrapping Machines Feature Semi-Automatic Shrink Chamber Fully Automatic Shrink Machine Cost Affordable for SMEs Higher upfront investment Operator Involvement Requires manual loading No operator needed after setup Production Rate Medium (300–600/hr) High (up to 1500/hr) Maintenance Basic upkeep Requires skilled technicians Best For Growing businesses High-output manufacturing lines Fully automatic systems are ideal for businesses processing tens of thousands of units daily. For everyone else, the semi-automatic option strikes a balance between efficiency and affordability. Which One Should You Choose for Your Business? Choose Shrink Chamber Machine if: You are a small business, startup, or have a limited budget Your packaging requirement is less than 500–800 units/day You need a portable and space-saving solution You work with low-volume packaging like

Shrink Chamber vs. Shrink Tunnel – Which One is Better for Your Business?

Shrink Chamber vs. Shrink Tunnel – Which One is Better for Your Business? Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Sleeve Shrink Wrapping Rotary Type Sleeve Shrink Wrapping Machine Automatic Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semi-Automatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 Name Email Message Send AI Generated In the world of modern packaging, shrink wrapping technology plays a vital role in improving product presentation, ensuring safety, and enhancing shelf life. Two of the most common machines used in shrink packaging are the Shrink Chamber Machine and the Shrink Tunnel Machine. But when it comes to choosing the right machine for your business, many manufacturers and business owners struggle to make the right choice. This blog breaks down the differences, benefits, applications, and suitability of each machine so you can decide which one is best for your packaging needs. Whether you are in the FMCG industry, pharmaceuticals, cosmetics, bottled water, or electronics, choosing the right shrink wrapping solution can help improve efficiency and reduce operational costs. What is a Shrink Chamber Machine? A shrink chamber machine is a compact, all-in-one shrink wrapping machine where sealing and shrinking take place inside a single chamber. The operator manually places the product inside a shrink film (usually PVC or Polyolefin), then places it in the chamber. Once the hood is closed, the machine seals the film and applies heat to shrink the film tightly around the product. Key Features: All-in-one operation: sealing + shrinking Compact and space-saving Easy to operate and maintain Ideal for low to medium volume production Best Suited For: Startups and small businesses Packaging DVDs, cosmetics, toys, gift boxes Shrink packaging in tight spaces like retail stores or workshops What is a Shrink Tunnel Machine? A shrink tunnel machine, also known as a heat tunnel, is an industrial-grade machine designed for high-speed and high-volume shrink wrapping. Products are first sealed using an L-Sealer or Web Sealer, and then conveyed through a heated tunnel where the shrink film shrinks uniformly around the product. Key Features: High-speed, continuous operation Suitable for automated production lines Uniform heat distribution Compatible with multiple shrink films Best Suited For: Medium to large scale industries Food industry, water bottle packaging, pharmaceuticals Bulk packaging like cartons, trays, and combo packs Shrink Chamber vs. Shrink Tunnel – Key Differences Feature Shrink Chamber Machine Shrink Tunnel Machine Operation Type Manual/Semi-Automatic Semi/Automatic Sealing & Shrinking Done together in one unit Sealing done separately, shrinking in tunnel Speed Lower speed, batch-based High speed, continuous flow Productivity 200–500 pcs/hour (approx.) 1000–3000 pcs/hour (based on model) Space Requirement Compact design Larger footprint Cost Budget-friendly Higher investment Target Business Small to medium enterprises Medium to large-scale industries Which One Should You Choose for Your Business? Choose Shrink Chamber Machine if: You are a small business, startup, or have a limited budget Your packaging requirement is less than 500–800 units/day You need a portable and space-saving solution You work with low-volume packaging like gift items, cosmetics, or boutique retail products Choose Shrink Tunnel Machine if: You are a manufacturer or exporter You require fast packaging of large quantities Your products are uniform in size or packed in cartons/trays You want to integrate the shrink tunnel into a production line Applications in Different Industries FMCG Industry: Shrink Tunnel Machine is ideal for bulk packaging of bottles, jars, cartons Shrink Chamber Machine is perfect for individual or combo packs in gift boxes Food & Beverage Industry: Use Shrink Tunnels for water

How Vertical Band Sealing Machines Improve Packaging Quality and Enhance Product Shelf Life

How Vertical Band Sealing Machines Improve Packaging Quality and Enhance Product Shelf Life Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Sleeve Shrink Wrapping Rotary Type Sleeve Shrink Wrapping Machine Automatic Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semi-Automatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 Name Email Message Send AI Generated In an increasingly competitive market, businesses must prioritize the quality and reliability of their product packaging. Whether you’re in the food, pharmaceutical, or consumer goods industry, packaging is a key factor that directly impacts product preservation, shelf life, and customer satisfaction. Among the most effective packaging solutions today are Vertical Band Sealing Machines, which offer superior sealing capabilities that enhance packaging quality while ensuring product longevity. These machines are crucial in ensuring airtight, tamper-proof seals that prevent contamination and degradation, ultimately protecting the integrity of the products inside. In this comprehensive guide, we’ll explore how vertical band sealing machines improve packaging quality and extend the shelf life of various products. 1. Airtight Seals in Vertical Band Sealing Machines for Enhanced Freshness One of the primary advantages of Vertical Band Sealing Machines is their ability to create airtight seals, which is essential for product preservation. In industries like food processing, pharmaceuticals, and chemicals, maintaining the freshness and integrity of the product is a top priority. Vertical Band Sealing Machines use advanced sealing technology to form a hermetic seal that prevents air, moisture, and contaminants from infiltrating the packaging. Benefits of Airtight Seals: Prevents Oxidation: By sealing out oxygen, vertical band sealers help prevent oxidation, which is a major cause of spoilage, especially in food products like snacks, dried foods, and powdered ingredients. Prevents Moisture Infiltration: Moisture can lead to mold growth, spoilage, and degradation of ingredients. The airtight seals created by vertical band sealers ensure moisture remains outside the packaging, maintaining product quality. Protects Against Contamination: Whether it’s dust, bacteria, or pollutants, the high-quality seals prevent external contaminants from entering the package, ensuring your product stays clean and safe until it reaches the consumer. 2. How Vertical Band Sealing Machines Preserve Nutritional Value and Quality For industries like food manufacturing, the preservation of a product’s nutritional value and quality is essential. Vertical Band Sealing Machines offer a precise and reliable sealing mechanism that helps maintain the product’s freshness, taste, texture, and nutritional content. How Sealing Machines Retain Nutritional Value: Protects Natural Ingredients: Many food products contain natural ingredients that are sensitive to air exposure. The airtight seals prevent oxidation and degradation, ensuring that essential vitamins, minerals, and flavors are preserved for longer. Retains Taste and Texture: Products like snacks, fruits, and bakery items are susceptible to changes in texture and flavor when exposed to air. Vertical Band Sealing Machines preserve these qualities, keeping products fresh and appealing for an extended period. 3. Temperature Control in Vertical Band Sealing Machines for Heat-Sensitive Products Certain products, especially in the pharmaceutical and chemical industries, are highly sensitive to temperature fluctuations. Vertical Band Sealing Machines offer customizable sealing processes, including the ability to adjust sealing temperature and speed to meet the unique requirements of heat-sensitive products. Advantages of Temperature Control in Sealing: Protects Sensitive Products: Pharmaceuticals, medical devices, and cosmetic products often require strict temperature control. Vertical Band Sealing Machines prevent overheating, preserving the integrity of the product while ensuring high-quality seals. Maintains Product Safety: The precise control of sealing temperature ensures that the packaging process does not compromise the safety of the product. This is crucial for items such

How to Choose the Right Band Sealer Machine for Your Product Type

How to Choose the Right Band Sealer Machine for Your Product Type Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Sleeve Shrink Wrapping Rotary Type Sleeve Shrink Wrapping Machine Automatic Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semi-Automatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 Name Email Message Send AI Generated In today’s competitive packaging industry, choosing the right sealing solution is critical for businesses aiming to improve packaging speed, maintain product freshness, and deliver a professional finish. Whether you’re in the food, pharmaceutical, chemical, or FMCG industry, investing in a reliable Band Sealing Machine can dramatically improve your packaging line’s efficiency, reduce labor costs, and enhance product presentation. However, with several models available—each designed for specific applications—how do you know which Band Sealer is ideal for your business? This detailed guide from AmarPack Machines Pvt Ltd, a leading manufacturer and exporter of packaging machines in India, breaks down each type of Continuous Band Sealing Machine and matches it with suitable product categories and industry applications. We also cover the benefits, ideal usage scenarios, and keyword-rich insights to help you make an informed decision and optimize your online searches. 1. Mini Vertical Model Band Sealing Machine Best Suited For: Lightweight pouches, small food packets, pharma sachets, spices, powders, and small-scale packaging lines. Industries: FMCG, Confectionery, Spices & Masalas, Pharmaceutical, Nutraceutical Why Choose the Mini Vertical Model? Compact structure makes it suitable for limited workspaces Efficient for sealing pouches filled with granular or powdered items Maintains upright position for liquids and powders to avoid spillage Low maintenance and user-friendly operation Key Features: Adjustable temperature and speed Stainless steel body for hygiene Ideal for batch packaging operations 2. Master Model – Vertical Band Sealer Best Suited For: Heavier pouches, medium-to-large food packs, liquid sachets, detergent pouches, and oil packs. Industries: Chemical, FMCG, Dairy, Lubricant, Agrochemical, Beverage Why Choose the Master Vertical Model? Heavy-duty frame for extended operational hours Can handle thicker laminates and multilayer pouches Prevents leakage in liquid products due to vertical alignment Designed for medium to high-volume packaging lines Key Features: High sealing strength Digital temperature controller Versatile for various pouch materials (LDPE, PP, Aluminum Foil, etc.) 3. Horizontal Mini Model Band Sealing Machine Best Suited For: Bakery items, namkeen, seeds, powder pouches, candies, medical kits. Industries: Food & Snacks, Bakery, Agriculture, Healthcare, Cosmetics Why Choose the Horizontal Mini Model? Suitable for sealing dry products that don’t require vertical handling Ideal for small and medium enterprises with limited automation Easy placement and operation with low energy consumption Key Features: Horizontal pouch feed Consistent sealing quality Cost-effective for startups and SMEs 4. Horizontal Master Model Band Sealing Machine Best Suited For: Bulk packaging of grains, pet food, hardware items, electronic components, fertilizers. Industries: Agro Products, Electronics, Pet Food, Hardware, Industrial Supplies Why Choose the Horizontal Master Model? Designed for large pouches and extended production lines Rugged construction ensures continuous, high-speed operation Guarantees uniform sealing across multiple layers Key Features: Can seal up to 15 kg pouches Option for conveyor height adjustment Suitable for printed and laminated pouches 5. Continuous Nitrogen Flushing Band Sealing Machine Best Suited For: Chips, dry fruits, snacks, spices, roasted snacks, powdered milk, protein supplements. Industries: FMCG, Snack Foods, Health Foods, Spices & Condiments Why Choose Nitrogen Flushing with Band Sealer? Extends shelf-life by creating a nitrogen-rich environment inside the pouch Prevents spoilage and maintains crispness in food items Adds value by offering tamper-evident, hygienic packaging Key Features: Built-in nitrogen flushing nozzle Adjustable gas flow

Top 5 Reasons Your Competitors Are Investing in Tube Filling Automation

Top 5 Reasons Your Competitors Are Investing in Tube Filling Automation Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Sleeve Shrink Wrapping Rotary Type Sleeve Shrink Wrapping Machine Automatic Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semi-Automatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 Name Email Message Send AI Generated In today’s fast-paced packaging industry, speed, precision, and hygiene have become non-negotiable. As a result, more and more businesses are shifting to automatic tube filling and sealing machines to upgrade their production lines. Whether you’re in the cosmetics, pharmaceutical, food, or chemical industry, chances are your competitors are already investing in automation — and for good reason. If you’re still using manual or semi-automatic tube fillers, you’re falling behind. Let’s explore the top 5 reasons why smart businesses are investing in automatic tube filling and sealing machines — and why you should consider doing the same. 1. Increased Production Speed and Efficiency Automatic tube filling and sealing machines are designed to dramatically improve the speed and efficiency of your packaging process. The automation allows for continuous, high-speed filling and sealing of tubes, making it possible to achieve hundreds to thousands of units per hour, depending on the model. This is a significant improvement over manual or semi-automatic systems, where speed is often limited by human labor. How Automation Transforms Your Production Line: Consistent and faster throughput: While manual methods might limit you to a few hundred tubes per day, an automated system can scale to thousands. Uninterrupted operation: These machines can work round-the-clock, significantly increasing production output without needing additional labor costs. Reduced downtime: Automatic changeover features and quick adjustments ensure minimal downtime during maintenance or product changes. This increased speed and efficiency mean you can meet market demand faster, reduce delivery times, and scale your operations more easily. 2. Consistent Quality and Precision Filling In industries like pharmaceuticals, cosmetics, and food, maintaining high-quality standards is paramount. Inconsistent fill volumes, poorly sealed tubes, and defective products can result in customer dissatisfaction, returns, and regulatory issues. One of the most significant advantages of investing in an automatic tube filling machine is its ability to deliver precision and consistent quality in every unit produced. Key Features That Ensure Consistent Quality: Servo-driven technology for accurate fill volumes, even for liquid, semi-solid, and paste-like substances. PLC (Programmable Logic Controller) systems that ensure precise control over the filling and sealing process, minimizing human error. Accurate sealing mechanisms that ensure each tube is sealed tightly to prevent leaks, ensuring your product remains fresh and intact. Minimal wastage: Automation reduces material waste due to precise filling and exact tube usage. These machines offer repeatable precision, which is vital for companies striving to build their brand’s reputation for quality. 3. Hygienic and GMP-Compliant Packaging Process As a business in the pharmaceutical or personal care industry, compliance with hygiene, safety, and regulatory standards is non-negotiable. Automatic tube filling machines are designed with these concerns in mind. Many of these machines are GMP-compliant (Good Manufacturing Practice) and built with hygienic materials like stainless steel and food-grade components to ensure your production line adheres to the highest standards. How Automatic Machines Ensure Hygiene and Compliance: Easy to clean surfaces: Stainless steel construction allows for quick and thorough cleaning, reducing the risk of contamination between batches. Clean-In-Place (CIP) technology: These systems ensure that all contact parts can be sanitized without disassembling the machine, preventing product contamination. FDA and GMP-compliant designs: Many automatic tube filling and sealing machines are manufactured

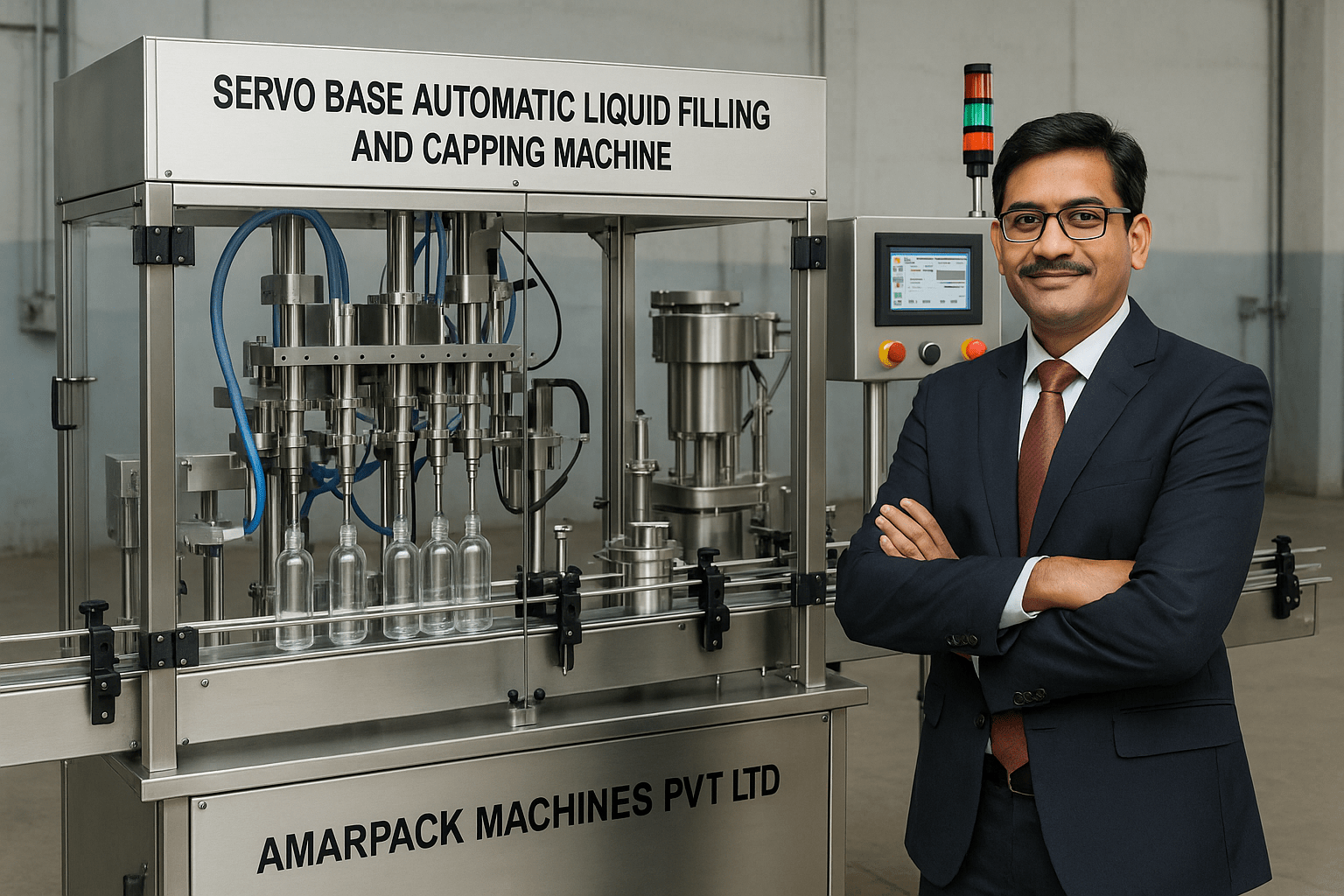

Why the Servo Base Automatic Liquid Filling and Capping Machine is a Game-Changer for the Beverage Industry

Why the Servo Base Automatic Liquid Filling and Capping Machine is a Game-Changer for the Beverage Industry Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Sleeve Shrink Wrapping Rotary Type Sleeve Shrink Wrapping Machine Automatic Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semi-Automatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 Name Email Message Send AI Generated In the fast-paced world of beverage manufacturing, efficiency, precision, and consistency are key to meeting consumer demands and staying ahead of the competition. One of the most significant innovations revolutionizing the industry today is the Automatic Liquid Filling and Capping Machine—specifically, those equipped with servo base technology. These machines, which combine advanced automation with superior control, have become an indispensable asset for beverage manufacturers looking to scale production without compromising on quality. Whether you’re dealing with carbonated drinks, juices, water, or alcoholic beverages, servo-based liquid filling and capping machines offer unparalleled benefits in terms of speed, accuracy, and operational efficiency. This blog delves into why the servo base liquid filling and capping machine is a game-changer for the beverage industry, highlighting the core benefits, features, and how it enhances production lines. What is a Servo Base Automatic Liquid Filling and Capping Machine? Before diving into the advantages, let’s first understand what a servo-based automatic liquid filling and capping machine entails. This system is a fully automated solution designed to: Fill liquid products into containers (such as bottles, cans, or pouches). Cap the containers securely with various types of caps (screw caps, crown caps, flip-top caps, etc.). The machine uses servo motors, which provide precise control over both the filling and capping processes. Unlike traditional filling systems, which rely on mechanical or pneumatic systems, servo technology uses digital motors that offer better control over speed, torque, and position. This innovation results in: Enhanced speed and accuracy Reduced wear and tear Increased flexibility and efficiency Lower operational costs in the long run Key Advantages of Servo Base Technology in Liquid Filling and Capping Machines 1. Increased Precision and Accuracy One of the biggest challenges in beverage manufacturing is maintaining consistent fill volumes, especially when dealing with liquids that vary in viscosity or contain carbonation. Servo motors offer superior control over the filling process, ensuring that each container receives the exact amount of liquid, reducing overfills or underfills. This accuracy not only minimizes wastage but also ensures that the final product adheres to industry standards and regulations. 2. Higher Speed and Efficiency The beverage industry is driven by high-volume production needs. Servo base automatic filling and capping machines excel in this regard, allowing manufacturers to increase production speeds without sacrificing quality. The servo motors can quickly adjust speeds to optimize the filling and capping process based on the type of liquid or container being processed. For example: Juices, water, and soft drinks are filled faster than thick or viscous liquids. Filling speed can be adjusted depending on the product, allowing for multi-product capabilities on a single machine. This scalability and flexibility help businesses meet changing demand patterns, particularly in the high-paced beverage industry. 3. Reduced Downtime and Maintenance Costs Traditional filling and capping machines require regular maintenance due to the mechanical components that wear over time. With servo motors, manufacturers experience less wear and tear and reduced maintenance costs. Servo-driven systems run efficiently for longer periods with less frequent breakdowns. Parts like motors, sensors, and belts require fewer replacements, lowering the total cost of ownership. The smart sensors integrated into the system can predict

Why Customized Conveyor Systems Are the Future of Smart Manufacturing

Why Customized Conveyor Systems Are the Future of Smart Manufacturing Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Type Rotary Type Automatic Type Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semiautomatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 Name Email Message Send AI Generated In the fast-paced and precision-driven world of modern manufacturing, conveyor systems play a pivotal role in improving efficiency, reducing labor, and ensuring timely product movement. As the demand for flexible, intelligent, and application-specific automation solutions increases, customized conveyor systems have emerged as a core component of smart manufacturing ecosystems. From packaging units to assembly lines, customized conveyors are transforming how industries operate by integrating automation, IoT technology, and modular design. This blog explores why investing in a customized conveyor system is not just a good idea—but a strategic move for manufacturers who want to stay competitive in 2025 and beyond. What Is a Customized Conveyor System? A customized conveyor system is a material handling solution designed and engineered to meet the specific needs of a manufacturing or packaging process. Unlike standard, off-the-shelf conveyor systems, these are built based on: Type of product being handled Speed and throughput requirements Space constraints Industry-specific hygiene or safety standards Integration with automation equipment Whether it’s a modular belt conveyor for packaging, a heavy-duty roller conveyor for industrial components, or a stainless steel food-grade conveyor for the food processing industry, customization enables flawless operations tailored to your unique production goals. Why Customized Conveyor Systems Are Leading the Future 1. Enhanced Operational Efficiency Tailor-made conveyor systems are designed to move products with minimal friction, precise alignment, and optimized speed. They significantly reduce manual handling and eliminate bottlenecks. For example: Automated conveyor systems integrated with sensors can adjust speeds based on workload. Smart conveyors can detect obstructions or damaged goods and reroute the flow. 2. Seamless Integration with Smart Manufacturing Technologies In 2025, Industry 4.0 is no longer a trend—it’s the standard. Customized conveyors integrate with: PLC systems IoT devices Robotics arms Vision inspection systems Barcode/RFID scanners This transforms a basic transport line into an intelligent material flow solution that enables real-time monitoring, predictive maintenance, and adaptive workflow changes. 3. Modular and Scalable Design Businesses grow, and so do their production needs. With modular conveyor systems, you can: Add or remove sections easily Switch to different belt materials Upgrade with new technologies Expand without replacing the entire setup This adaptability ensures your investment continues to pay off even as your operations evolve. 4. Industry-Specific Compliance and Safety Certain industries require adherence to strict guidelines. For example: Pharmaceutical conveyor systems must meet FDA or GMP standards. Food-grade conveyors must be corrosion-resistant and easy to sanitize. Chemical and hazardous goods conveyors must be explosion-proof and sealed. Customizing your conveyor ensures that your operations stay compliant, safe, and efficient. 5. Space Optimization and Layout Flexibility Standard conveyor systems may not always fit perfectly into your factory floor layout. A customized conveyor layout can be designed around: Floor obstacles Machine placements Multi-level operations Narrow spaces or corners This results in maximum space utilization and smoother workflow transitions. Real-World Applications Across Industries ✅ Packaging Industry Customized conveyors in packaging lines allow synchronized product movement, labeling, sealing, and sorting in one streamlined system. ✅ Food & Beverage Conveyors made of stainless steel or food-grade belts ensure hygiene, temperature resistance, and gentle handling of delicate products. ✅ Pharmaceutical From tablet sorting to bottle filling, conveyors play a critical role in precision-driven, dust-free, sterile environments. ✅ E-commerce &

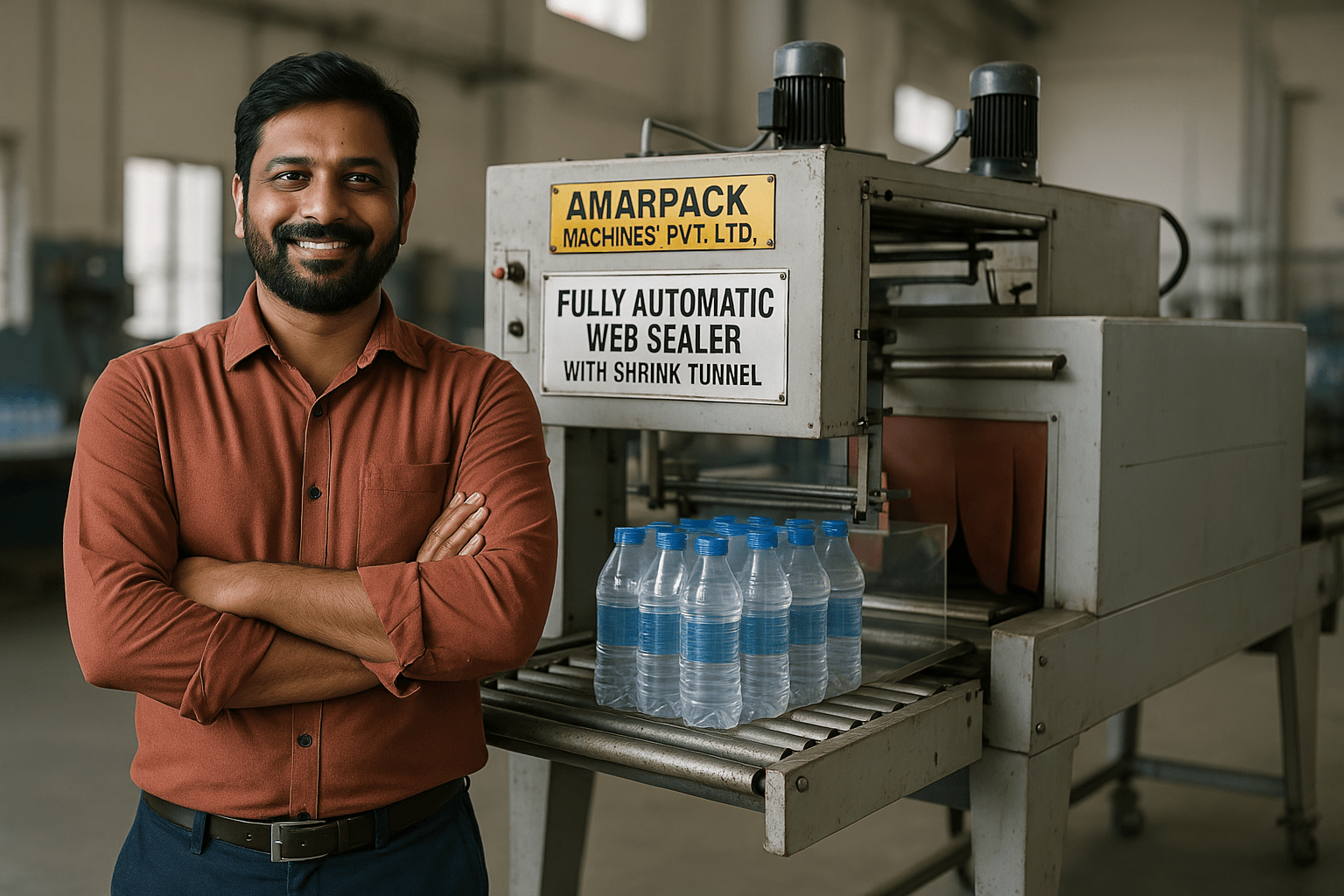

Top Industries Benefiting from Semi Automatic Web Sealer with Shrink Tunnel Machines in 2025

Top Industries Benefiting from Semi Automatic Web Sealer with Shrink Tunnel Machines in 2025 Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Sleeve Shrink Wrapping Rotary Type Sleeve Shrink Wrapping Machine Automatic Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semi-Automatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 Name Email Message Send AI Generated In 2025, businesses across various sectors are under constant pressure to streamline their packaging operations, reduce manual labor, and deliver products with secure, professional finishes. One machine that is proving to be indispensable for mid to high-volume packaging lines is the Semi Automatic Web Sealer with Shrink Tunnel Machine. This blog explores the top industries that are actively benefiting from this powerful packaging solution, along with why it’s a smart investment for manufacturers seeking durability, flexibility, and cost-efficiency in their production environment. What is a Semi Automatic Web Sealer with Shrink Tunnel Machine? A Semi Automatic Web Sealer with Shrink Tunnel is a packaging machine designed to wrap and seal products using shrink film, followed by heat shrinking via a tunnel. It automates the sealing and shrinking process for medium to large products like cartons, bottles, boxes, and more. Key Features: L-type or sleeve sealing mechanism PLC-based or relay control operation Heavy-duty conveyor with adjustable speed High-temperature resistant tunnel with controlled airflow Compatible with polyolefin (POF), LDPE, and PVC shrink films Why This Machine is in High Demand in 2025 As industries scale operations and aim for automation, the semi automatic shrink packaging machine becomes essential. It bridges the gap between manual labor and full automation, offering a perfect blend of speed, efficiency, and control without excessive investment. Top 6 Industries That Benefit from Semi Automatic Web Sealer with Shrink Tunnel Machines 1. Beverage & Bottled Water Industry With rising demand in the water and soft drink sector—especially during summer—packaging multiple bottles quickly and securely is critical. The machine enables bundle packaging of bottles (like 6-pack or 12-pack), using LDPE shrink film, protecting against spillage and damage during transport. Common Applications: Mineral water bottles Juice packs Carbonated beverages Energy drink bottles 2. Food & FMCG Industry In the fast-moving consumer goods (FMCG) sector, packaging must be fast, clean, and visually appealing. This machine ensures tamper-proof packaging, ideal for food products like jars, boxes, trays, and canned items. It’s widely used for secondary packaging before shipment. Common Applications: Snacks and biscuits cartons Ready-to-eat food trays Pickle or jam jars Frozen foods in cartons 3. Pharmaceutical & Healthcare Industry Safety and hygiene are paramount in pharma packaging. This machine provides dust-free, durable shrink wrapping for cartons, medical devices, bulk medicines, and surgical product boxes. It’s especially favored by exporters for its neat and tamper-evident sealing. Common Applications: Syringe or vial boxes Surgical kit cartons Herbal product packaging Bulk medicine packaging https://youtu.be/RjwZ5245WQI 4. Cosmetic & Personal Care Industry Cosmetic brands use shrink wrapping not only for protection but also to enhance product appearance. This machine is used to seal kits, bottles, and promotional gift packs. It supports clean, transparent shrink film wrapping, giving products a professional finish. Common Applications: Skin care combo kits Shampoo and conditioner bottle packs Gift hampers Lipstick and beauty boxes 5. E-commerce & Logistics Sector With online orders increasing in bulk, companies require strong and secure secondary packaging to avoid in-transit damage. Semi automatic web sealers shrink-wrap large boxes or combined items, reducing packaging cost and increasing handling speed. Common Applications: Electronics and gadgets Book bundles Subscription boxes Bulk courier cartons 6. Home

Future of Packaging: Why Fully Automatic Web Sealers With Shrink Tunnel Machines Are Here to Stay

Future of Packaging: Why Fully Automatic Web Sealers With Shrink Tunnel Machines Are Here to Stay Product menu Bottle Shrink Wrapping Machine Portable Shrink Wrapping Machines Standard Shrink Wrapping Machine Heavy Duty Model No. APST -200 Heavy Duty Shrink Wrapping Machines-300 Shrink Tunnel Machine with Taffan Glass Shrink Tunnel Machine – Slate chain Steam Heat Shrink Tunnel Machine Roter Sleeve Shrinking Machine Web sealer With Shrink Tunnel Machine – Boxes Semi-Automatic Web Sealer Machine Conveyorised Automatic Shrink Wrapping Machine Automatic Coil wrapping Machine Web sealer with Shrink Tunnel Machine – Bottles Automatic Shrink Wrapping Machine with Collator for Bottles Semi-Automatic (bottles) Continuous Band sealing Machine Mini Vertical Model Horizontal Master Model Horizontal Mini Model Master Model – Vertical Continuous Nitrogen Flushing Machine Continuous Band sealer Machine with IPC System Continuous Band Sealing Machine With FLP L-sealer with shrink tunnel Machine Manual L-sealer Online L-sealer Pneumatic L-sealer Fully Automatic L-Sealer Fork / Mobile type sealing machine Direct Heat Type Fork sealing Machine Impulse Type Fork Sealing Machine Tong sealer Machine Impulse Type Tong sealer Machine Heat Type Ting sealer Machine Automatic Liquid Filling Line Semi Liquid Filling Machine Automatic Liquid Filling & Capping Line Automatic Tube Sealing Machine Automatic Tube Filling & Sealing Machine Manual Tube sealing Machine Semi-Automatic Tube sealing Machine Induction Sealing Machine Automatic Induction Sealing Machine Manual Induction sealing machine BOX Strapping Machine Packway Semi-Automatic Strapping Machine Automatic Box Strapping Machine Semi-Automatic Box Strapping Machine Fully Automatic Carton Box Strapping Machine Carton Taping Machines Semi-Automatic Carton Taping Machine Automatic Carton Taping Machine Fully Automatic Carton Folding with Taping Machine Conveyor System PVC PU belt conveyor Roller Conveyors Gravity Roller Conveyors Line shaft Roller Conveyors Tube Crimping Machine Manual Tube crimping machine Pneumatic Tube Crimping Machine Manual Heat Sealing Machine Foot sealer Machine Foot Direct Heat Sealer Machine Foot Impulse Sealer Machine Pneumatic Foot Sealer Machine Vacuum Packaging Machine Table top Vacuum Packaging Machine Commercial Vacuum Packaging Machine Door type Vacuum Packaging Machine Table top Nozzle type Vacuum Packaging Machine Vertical Closed Chamber type Vacuum Packaging Machine Double chamber Vacuum Packaging Machine Nozzle Type Vacuum Packaging Machine Multi Nozzle type Chamber less Vacuum Packaging Machine Sleeve shrink Machine Manual Type Rotary Type Automatic Type Sleeve shrink Applicator Machine Paste filling machine Manual Paste filling machine Semiautomatic Paste Filling Machine Four Side Sealing & Shrinking Packing Machine Auger filling machine Automatic-Auger Filling Machine Semiautomatic Auger filling machine Automatic Flow Wrapping Machine Pneumatic Sealer Machine Pneumatic Direct heat sealer Machine Pneumatic Impulse Sealer Machine FLP Pneumatic Sealer Machine FLP with PLC Pneumatic Sealer Machine Foot Pneumatic Heat sealer Machine Horizontal Pneumatic Sealer Machine Carton Box Stretch Wrapping Machine Mini Cartoon Stretch wrapping machine Pallet Stretch wrapping machine Pre- stretch Wrapping machine Hamburger Toggle Menu +91 9821778501 sales@amarpackaging.com 1001, Fortune Emporio, Opp Thakur Mall Mira Road – 401107 Name Email Message Send AI Generated In the rapidly evolving landscape of packaging, businesses across industries are switching from manual to automated systems. One of the most game-changing innovations in recent years is the Fully Automatic Web Sealer With Shrink Tunnel Machine. It combines the precision of a web sealer with the heat efficiency of a shrink tunnel, creating the ideal solution for companies aiming for high output and superior packaging. Whether you’re in pharmaceuticals, food, cosmetics, lubricants, edible oil, pesticides, or beverages, this machine has become a vital part of modern production lines. What Is a Shrink Tunnel Machine? A shrink wrapping machine is used to wrap products in plastic film, which is then heated in a shrink tunnel to create a tight, secure package. These machines come in several types: Shrink Wrap Machine (manual or semi-auto) Semi-Automatic Shrink Wrap Machine Automatic Shrink Wrapping Machine Shrink Wrapping Machine with Web Sealing and Shrink Tunnel Shrink Wrapping Machine with Automatic Bottle Collating and Pneumatic Pusher These machines are commonly used for wrapping sweets, gift packets, confectionery, bottles, cosmetics, cartons, jerry cans, PET bottles, cups, and boxes. The Power Combo: Web Sealing + Shrink Tunnel The Fully Automatic Web Sealer With Shrink Tunnel Machine integrates: Web Sealing: To align, bundle, and seal the products precisely Shrink Tunnel: To shrink the film tightly around the product using hot air circulation This dual-function system makes it ideal for high-speed production lines, particularly in bottle shrink wrapping, shrink packaging, and PVC/PE shrink film applications. Where It’s Used: Industry Applications This machine supports a wide range of industries: Pharmaceutical, Cosmetic, Lubricant, Edible Oil, Food Products Pesticides, Distilleries, Breweries Packaging production lines for Beer, Beverage, Pure Water, Fruit Juice, Dairy Products It’s also widely used to collate bottles, tins, containers with/without mono cartons, making it a perfect solution for businesses needing flexible shrink packaging solutions. Benefits of Fully Automatic Shrink Wrapping Machines Time-Saving: Compared to manual or semi-automatic shrink wrapping machines, the automated version significantly reduces packaging time. Labor Cost Reduction: One operator can control an entire line. Improved Productivity: Handles large volumes of products quickly. Better Product Presentation: Clean, tight, and professional finish. Versatility: Works on drinking water bottles, PET bottles, glass bottles, cups, and cartons. Why Indian Manufacturers Lead the Market Indian suppliers like AmarPack Machines Pvt Ltd are globally recognized as reliable shrink wrapping machine manufacturers in India. They offer: Heavy-duty machines with customizable features Global export standards Cost-effective solutions Responsive after-sales service This is why India has become a hub for shrink wrapping machine supplier India listings, trusted by clients across continents. https://youtu.be/0e5TS2-BBOs Why This Machine Is Future-Proof The Fully Automatic Web Sealer With Shrink Tunnel Machine is built to handle future demands such as: High-speed automation Energy-efficient shrink tunnels Smart bottle collating systems Pneumatic pushers for consistent feeding Adaptability to changing product SKUs It’s perfect for modern operations requiring shrink sleeve applicators, bottle shrink wrapping machines, and shrink packaging machines for bulk production. Invest in Long-Term Packaging Success Whether you’re packaging food, pharmaceuticals, cosmetics, or industrial goods, a Fully Automatic Web Sealer With Shrink Tunnel Machine is the future-ready solution. With built-in shrink wrap machine technology and shrink tunnel machine compatibility, this system transforms