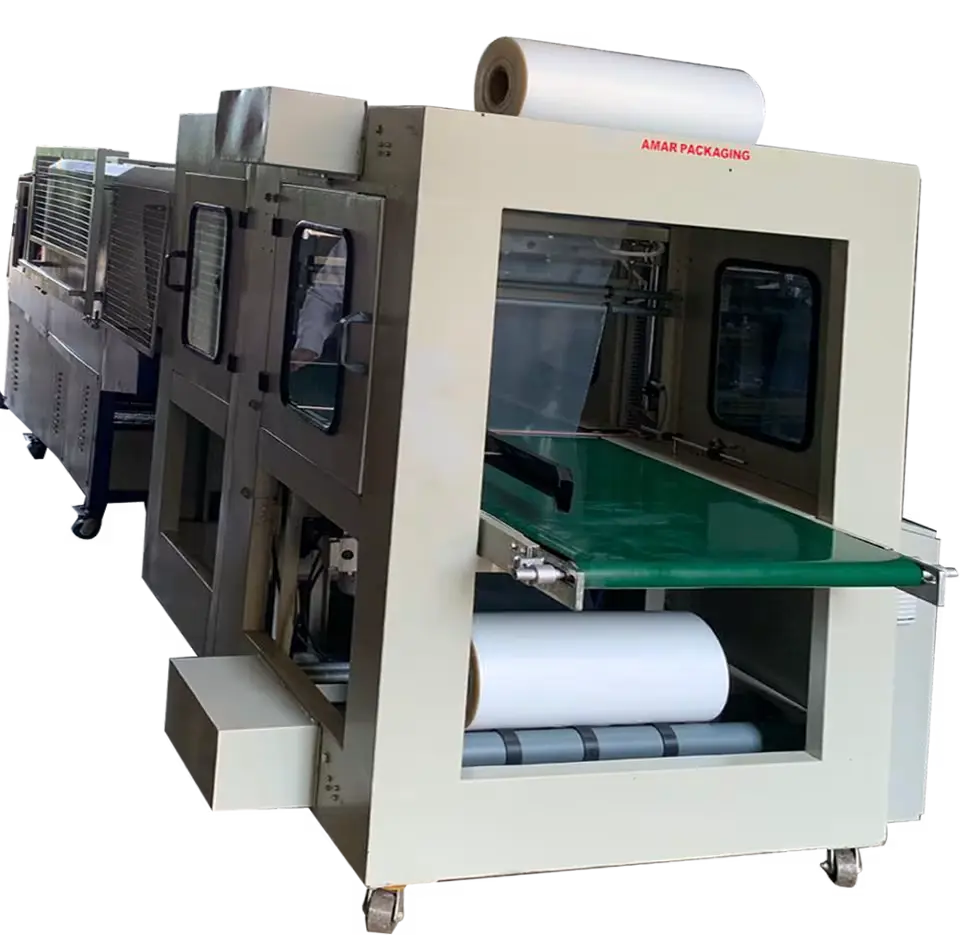

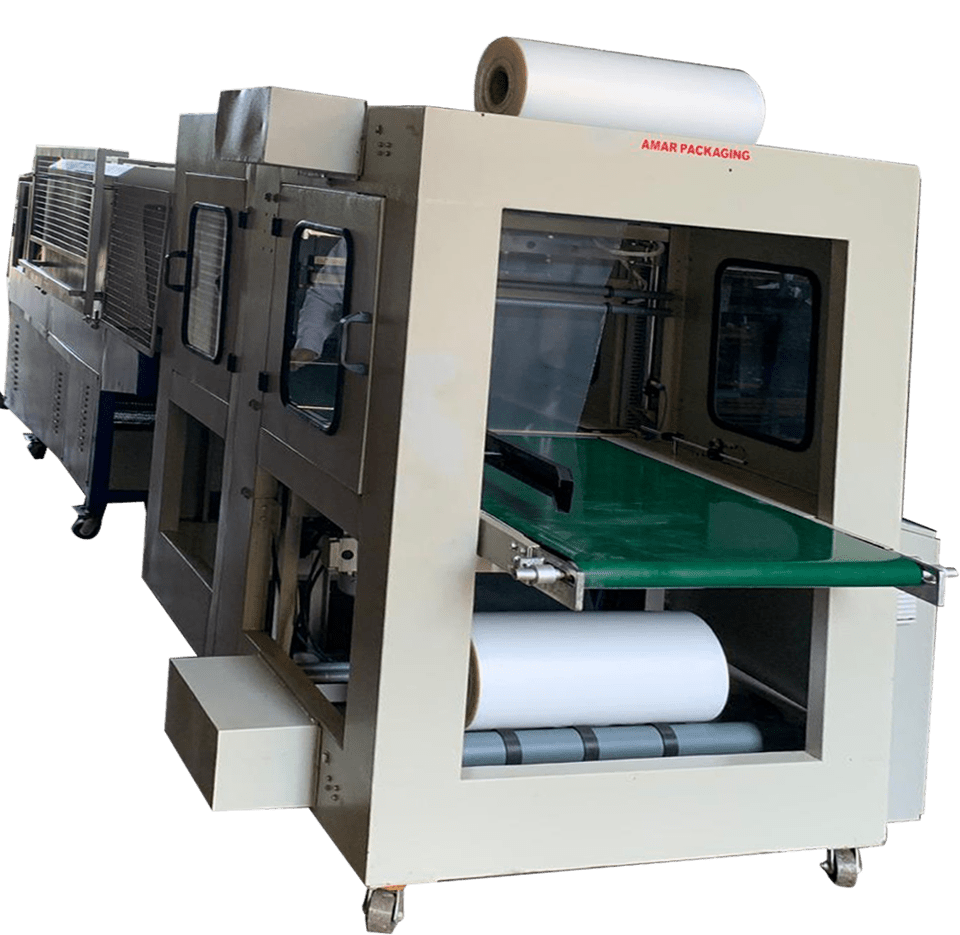

A Shrink Tunnel Machine applies heat to shrink film tightly around products, ensuring protection and enhancing shelf appeal. Ideal for food, beverage, pharmaceutical, and FMCG industries.

Learn More

Perfect for medium to high-volume packaging. Seals in L-shaped film then shrinks for a professional finish—ideal for food, cosmetics, and retail.

Learn More

Heavy-duty packaging solution for cartons, bottles, and bulk items. Ensures tight, tamper-proof finish.

Learn More

Uses electromagnetic induction to seal caps with foil for leak-proof, tamper-evident packaging—ideal for pharma, food, and cosmetics.

Learn More

Efficient bulk packaging solution for secure, professional shrink-wrap finishes.

Learn MoreFrom shrink wrapping to automated conveyors, our solutions are engineered for speed, durability, and global packaging standards.

Our shrink tunnel machines feature adjustable conveyor speeds.

View Category

Extend shelf life and freshness with our industrial vacuum sealers.

View Category

Precision filling for oils, juices, pharma, and chemical products.

View Category

Leak-proof sealing for food, medical & industrial packaging lines.

View Category

Perfect for eCommerce and logistics — secure, fast, and firm wrapping.

View Category

Automate movement and packaging with robust, scalable conveyors.

View Category

Is trusted and top-rated packaging machine manufacturer in India, proudly serving industries since 1998. With over 25 years of expertise, we design and deliver advanced shrink tunnel machines, automatic shrink wrap machines, and heat shrink packaging solutions tailored to diverse production needs. Our range includes efficient and customizable L-sealers with shrink tunnels, known for durability, speed, and consistent performance. Backed by cutting-edge technology and a customer-focused approach, our machines are ideal for food, pharmaceutical, FMCG, logistics, and industrial packaging applications.

We offer automatic, semi-automatic, and custom packaging systems designed to improve packaging quality and production efficiency. AmarPack’s commitment to quality and innovation has earned the trust of over 100+ global brands, making us one of the most reliable packaging machinery exporters in India. Choose AmarPack for robust, high-speed, and cost-effective packaging equipment built to meet international safety and performance standards.

Amarpack Machines Pvt Ltd is a leading packing machines manufacturer offering a wide range of high-quality packing machines, including Shrink Wrapping Machine, Conveyor System, Shrink Tunnel Machine, pouch packing machines, vacuum packing machines, and sealing machines for diverse industries. Whether you need an automatic machine, semi-automatic machine, manual machine, or fully-automatic machine, we deliver the right pack machine solution tailored to your production needs.

As trusted packaging machine manufacturers and packaging machines Exporter, we specialize in durable and efficient weigher machines, pkg machines, and machine sealing systems that ensure precision and performance. From seal packaging and sealing packing to pouch packaging and packing plastic bag handling, our machines guarantee excellence in every process. We also provide solutions for specialized applications like pop corn packing, food packaging, and packing material automation. Whether you’re packing individual items or complete packing packages, we have all products to streamline your workflow. Discover the best packing machine price and experience innovation with AmarPack Machines Pvt Ltd — your one-stop solution for all packing and packaging needs.

Follow us on Instagram, Facebook, and YouTube for the latest updates!

OUR MISSION

To deliver high-performance, globally recognized packaging machinery and sealing systems that improve production across industries like food, beverage, chemical, and pharma.

OUR VISION

To be the most innovative and reliable packaging machines manufacturer and exporter from India, recognized for delivering efficiency and automation worldwide.

OUR GOAL

To expand our global reach while offering scalable and affordable packaging solutions. We aim to lead in quality, technology, and customer satisfaction across every market we serve.

Tailored packaging solutions trusted across leading sectors.

Packaging solutions for snacks, sauces, bottles, and ready meals.

Clean, secure, and tamper-proof packaging for medicines and supplements.

Attractive and durable packaging for creams, tubes, and beauty products.

Smart packaging for boxed goods, kits, and online deliveries.

Leak-proof and safety-first packaging for liquids and powders.

Pallet wrapping and bulk packaging for secure transport.

Founded in 1998 in Mumbai, India, AmarPack Machines Pvt. Ltd. is one of India’s leading manufacturers and exporters of premium packaging machines. Read More

GST No. 27AAZCA2345J1Z6

Get a quick quote from our experts. Fast response guaranteed!