In the ever-evolving world of industrial packaging, businesses are increasingly searching for solutions that ensure maximum load security, durability, and operational efficiency. As we step further into 2025, the Pallet Hood Shrink Wrapping Machine has emerged as a revolutionary technology, streamlining packaging operations across warehouses, manufacturing units, logistics hubs, and export businesses.

This blog dives deep into how this machine is reshaping the future of packaging, why it’s preferred over conventional methods, its role in different industries, and everything you need to know before investing in one. Whether you’re a procurement manager, plant head, or business owner, this comprehensive guide answers all your questions.

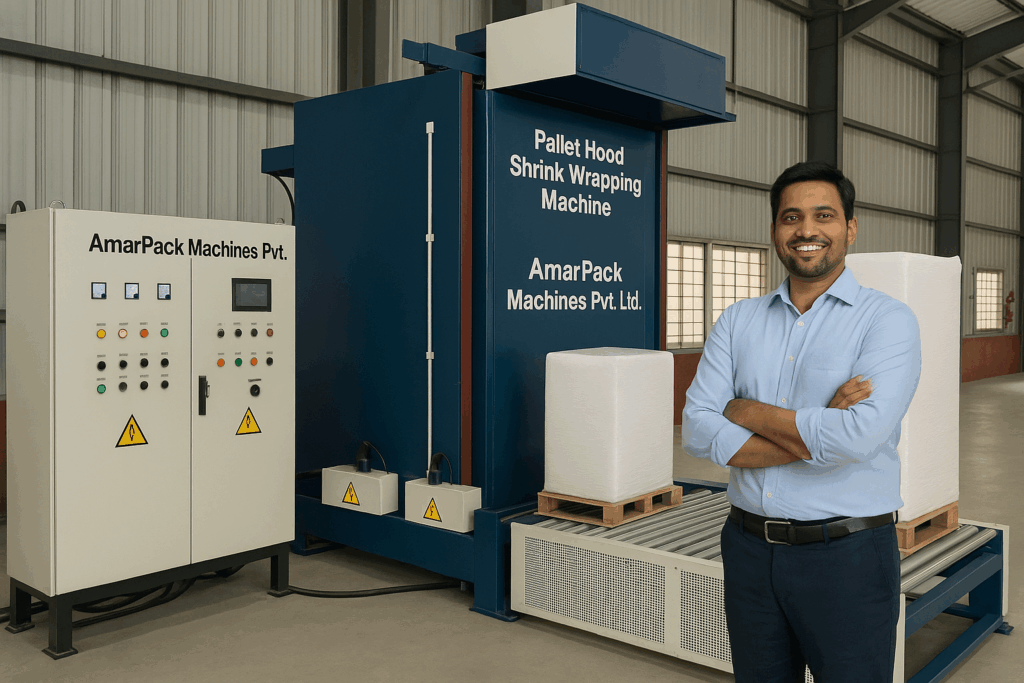

A Pallet Hood Shrink Wrapping Machine is designed to apply a pre-cut shrink film hood over a palletized load and then apply heat to shrink the film tightly around the products. The result? A clean, secure, and highly protective wrap that holds the pallet load firmly in place.

Unlike manual stretch wrapping, the shrink hood technique forms a sealed, weather-resistant, and tamper-proof layer around the load, making it ideal for long-distance transport, export packaging, and outdoor storage.

Key Components:

1. Superior Load Stability

The shrink hood tightly conforms to the shape of the product load, locking it in place. This eliminates the risk of shifting or falling during transit, reducing product damage.

2. All-Weather Protection

The film is resistant to dust, water, UV rays, and temperature changes, making it ideal for industries with outdoor storage or global shipping.

3. Tamper Evident Packaging

If the shrink film is tampered with, it becomes immediately noticeable, enhancing product safety and anti-theft measures.

4. Highly Automated Process

Modern machines from top manufacturers like AmarPack Machines Pvt Ltd offer fully automatic operation, significantly cutting down on labor costs and increasing throughput.

5. Custom-Fit Film Saves Material

The hood is pre-cut to match the pallet dimensions, which means no extra film wastage, as commonly seen in stretch wrapping.

6. Professional Packaging Appearance

Shrink-wrapped pallets appear clean, professional, and uniform, improving brand perception in B2B and B2C deliveries.

| Feature | Stretch Wrapping | Shrink Hood Wrapping |

|---|---|---|

| Load Stability | Medium | High |

| Tamper Resistance | Low | High |

| Weather Protection | Low | Very High |

| Film Wastage | High | Minimal |

| Aesthetic Finish | Moderate | Excellent |

| Cost Over Time | Higher | Lower (due to durability) |

| Automation Level | Semi-Automatic/Manual | Fully Automatic |

Customizable for Multiple Pallet Sizes

Heavy-Duty Construction for 24×7 Use

Energy-Efficient Heating System

User-Friendly Touchscreen Interface (PLC Based)

Safety Interlocks and Emergency Stop System

Compatible with LDPE, Polyethylene, and Barrier Films

Low Maintenance Design with Easy Spare Availability

Stretch wrapping stretches film around the load manually or semi-automatically, while shrink hood wrapping uses heat to shrink film tightly over the load, offering superior stability and protection.

Yes, AmarPack machines come with adjustable mechanisms and smart sensors to accommodate varying pallet heights.

LDPE shrink films can be recycled and are more efficient than excess-use stretch wraps, reducing your plastic footprint.

No. Our machines feature safety sensors, auto shut-off features, and protective insulation to ensure maximum operator safety.

Routine cleaning, checking heat elements, and periodic servicing. AmarPack provides full training and maintenance support.

With over 25 years of experience, AmarPack Machines Pvt Ltd is a trusted name in the manufacturing and export of high-performance packaging machines, including our flagship Pallet Hood Shrink Wrapping Machines.

Exported to 20+ countries

ISO and CE-certified machinery

Proven track record with top brands like Colgate, Cipla, HUL, Flipkart

Expert engineers and strong after-sales support

We don’t just sell machines, we provide complete packaging solutions.

Founded in 1998 in Mumbai, India, AmarPack Machines Pvt. Ltd. is one of India’s leading manufacturers and exporters of premium packaging machines. Read More

GST No. 27AAZCA2345J1Z6

Get a quick quote from our experts. Fast response guaranteed!