In the fast-paced and precision-driven world of modern manufacturing, conveyor systems play a pivotal role in improving efficiency, reducing labor, and ensuring timely product movement. As the demand for flexible, intelligent, and application-specific automation solutions increases, customized conveyor systems have emerged as a core component of smart manufacturing ecosystems.

From packaging units to assembly lines, customized conveyors are transforming how industries operate by integrating automation, IoT technology, and modular design. This blog explores why investing in a customized conveyor system is not just a good idea—but a strategic move for manufacturers who want to stay competitive in 2025 and beyond.

A customized conveyor system is a material handling solution designed and engineered to meet the specific needs of a manufacturing or packaging process. Unlike standard, off-the-shelf conveyor systems, these are built based on:

Whether it’s a modular belt conveyor for packaging, a heavy-duty roller conveyor for industrial components, or a stainless steel food-grade conveyor for the food processing industry, customization enables flawless operations tailored to your unique production goals.

1. Enhanced Operational Efficiency

Tailor-made conveyor systems are designed to move products with minimal friction, precise alignment, and optimized speed. They significantly reduce manual handling and eliminate bottlenecks. For example:

2. Seamless Integration with Smart Manufacturing Technologies

In 2025, Industry 4.0 is no longer a trend—it’s the standard. Customized conveyors integrate with:

This transforms a basic transport line into an intelligent material flow solution that enables real-time monitoring, predictive maintenance, and adaptive workflow changes.

3. Modular and Scalable Design

Businesses grow, and so do their production needs. With modular conveyor systems, you can:

This adaptability ensures your investment continues to pay off even as your operations evolve.

4. Industry-Specific Compliance and Safety

Certain industries require adherence to strict guidelines. For example:

Customizing your conveyor ensures that your operations stay compliant, safe, and efficient.

5. Space Optimization and Layout Flexibility

Standard conveyor systems may not always fit perfectly into your factory floor layout. A customized conveyor layout can be designed around:

This results in maximum space utilization and smoother workflow transitions.

✅ Packaging Industry

Customized conveyors in packaging lines allow synchronized product movement, labeling, sealing, and sorting in one streamlined system.

✅ Food & Beverage

Conveyors made of stainless steel or food-grade belts ensure hygiene, temperature resistance, and gentle handling of delicate products.

✅ Pharmaceutical

From tablet sorting to bottle filling, conveyors play a critical role in precision-driven, dust-free, sterile environments.

✅ E-commerce & Logistics

In fast-moving warehouses, automated sorting conveyor systems ensure timely order fulfillment, barcode scanning, and package routing.

✅ Automotive & Engineering

Heavy-duty conveyors are custom-built for handling parts like engines, chassis, or other metal components with precision and strength.

When customizing a conveyor system for smart manufacturing, look for:

These features enhance not only functionality but also predictive maintenance, minimizing unplanned downtimes.

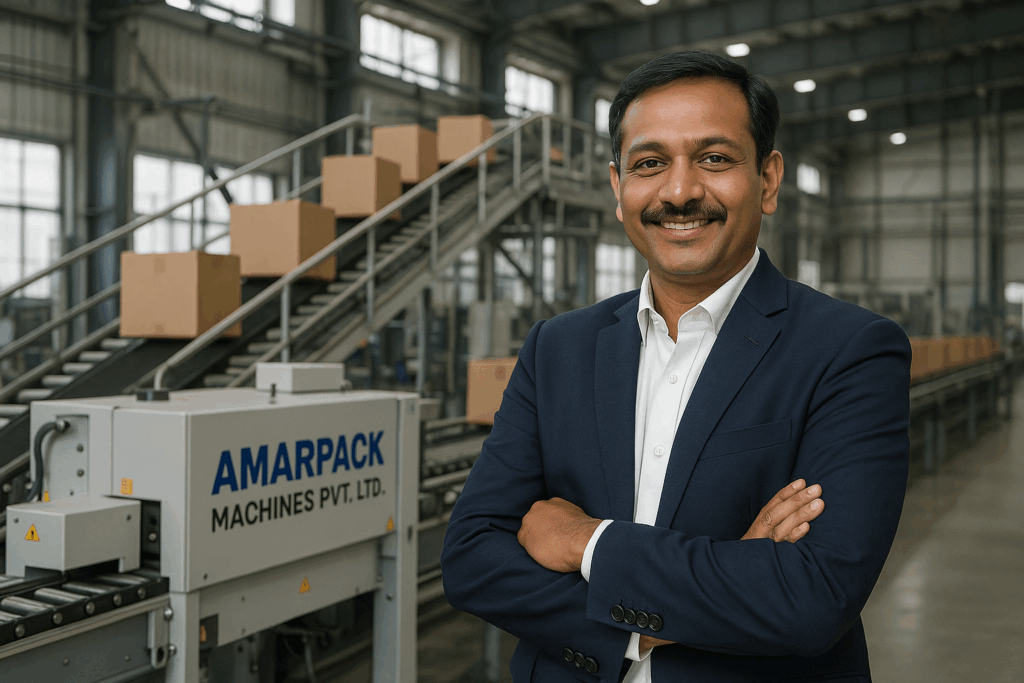

At AmarPack Machines Pvt Ltd, we don’t believe in one-size-fits-all. Our team works closely with clients to design, build, and implement conveyor systems that match their exact manufacturing needs. With 25+ years of experience, we’ve delivered solutions for industries such as:

Our conveyor systems are manufactured using premium-grade components, designed for high durability, low maintenance, and long-term performance. We also offer export-ready systems to countries like UAE, Saudi Arabia, Nigeria, Kenya, Nepal, and the Philippines

As the world moves toward automation, smart factories, and industry-specific optimization, customized conveyor systems are the logical next step. Whether you’re upgrading an old system or building a new plant, choosing the right conveyor setup can redefine your production output, safety, and operational excellence.

Future-proof your business with customized conveyor systems and move ahead with confidence in 2025 and beyond.

Founded in 1998 in Mumbai, India, AmarPack Machines Pvt. Ltd. is one of India’s leading manufacturers and exporters of premium packaging machines. Read More

GST No. 27AAZCA2345J1Z6

Get a quick quote from our experts. Fast response guaranteed!