In today’s fast-paced market, product presentation, protection, and operational efficiency are paramount for businesses of all sizes. From safeguarding goods during transit to enhancing shelf appeal, the right packaging solution can make all the difference. When it comes to boxing and bundling products, automatic box shrink wrapping machines stand out as a highly effective and versatile solution.

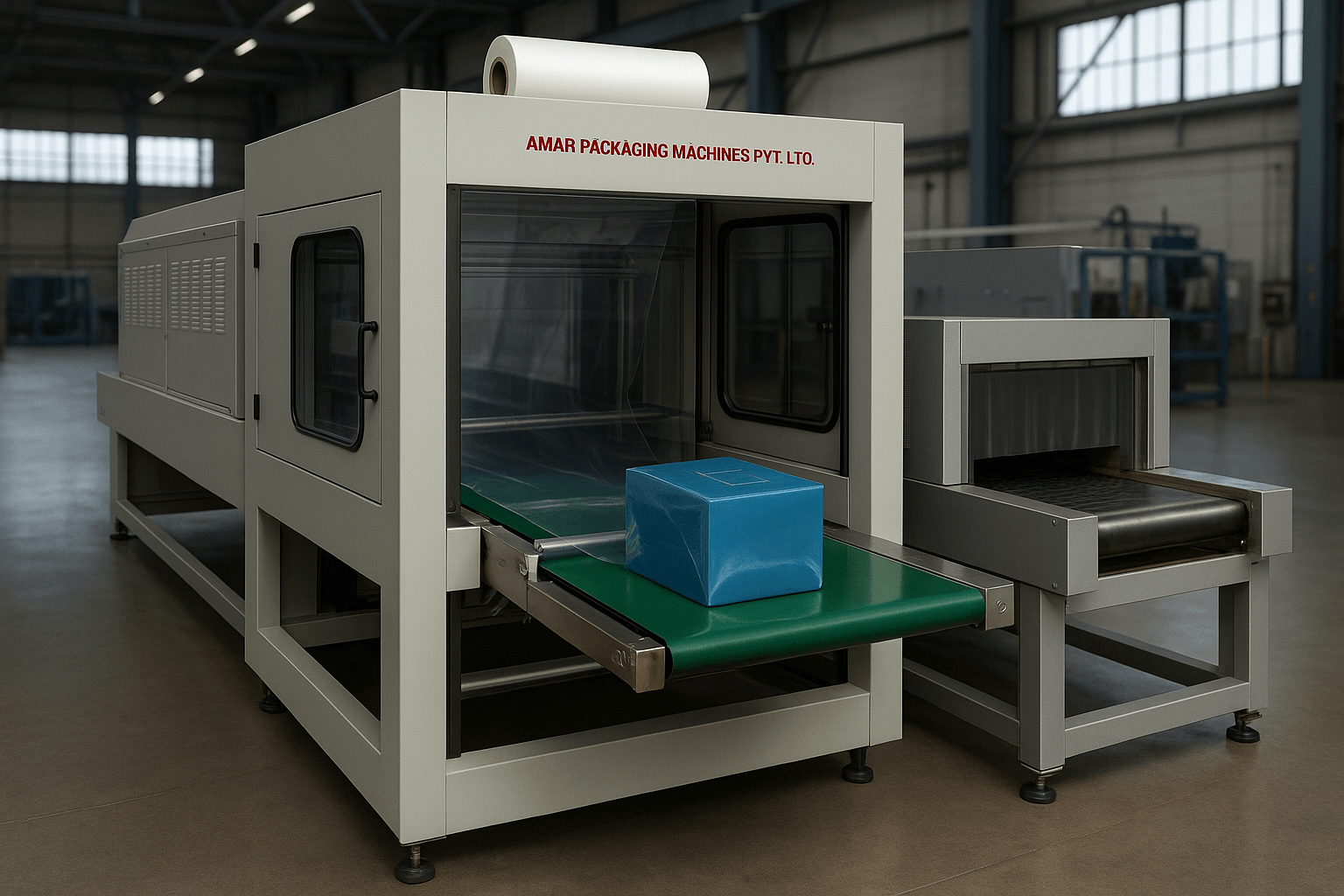

This comprehensive guide will walk you through the world of automated shrink wrapping, focusing on the two predominant systems – Web Sealers with Shrink Tunnels and L-Sealers with Shrink Tunnels – exploring their semi-automatic and fully automatic variants, and illuminating how investing in these machines can revolutionize your business operations.

Shrink wrapping involves encasing a product or group of products in a loose polymer film, which then shrinks tightly around the items when subjected to heat. For boxes, this creates a secure, tamper-evident, and aesthetically pleasing package. Beyond the visual appeal, shrink wrap offers:

When considering an automatic system for shrink wrapping boxes, you’ll primarily encounter two distinct technologies, each with its unique sealing mechanism and ideal applications:

A web sealer, also known as a continuous side sealer or flow wrapper, creates a continuous sleeve of film around the product before a cross-seal is made.

An L-sealer gets its name from its distinctive L-shaped sealing bar, which creates two seals simultaneously.

Both web sealers and L-sealers are available in semi-automatic and fully automatic configurations, catering to different production scales and operational needs.

Semi-automatic models offer a balanced blend of manual input and automated processes, making them a popular choice for growing businesses or those with moderate production volumes.

Fully automatic models represent the pinnacle of efficiency, integrating seamlessly into high-speed production lines with minimal human intervention.

Investing in the right shrink wrapping machine is more than just buying equipment; it’s a strategic decision that drives tangible business benefits:

Selecting the ideal automatic box shrink wrapping machine requires careful consideration of your specific needs:

An Automatic Web Sealer with Shrink Tunnel excels in high-speed, continuous packaging for a wide array of products, particularly those requiring multipacks or larger bundles. It’s ideal for creating tight, professional wraps around items like Water Bottle Bundles, Soft Drink Bottle Multipacks, Juice Bottle Packs, Oil Bottle Bundles, and Ghee Jar Multipacks. Industrial and retail bulk packaging also benefit greatly, including Canned Food Packs, Beer Bottle Packs, Detergent Powder Bags, and Floor Cleaner Bottle Combos. For electronics and home goods, it perfectly handles Electronic Gadget Boxes, LED Bulb Packs, Electric Kettle Boxes, Wire Bundle Packs, Fan Boxes, and Home Appliance Boxes. It’s also frequently used for larger stationery and office supplies such as Reams of Paper (5-Pack) and File Bundle Packs, as well as specialized items like Pharmaceutical Bottle Trays, Industrial Bearing Packs, and Paint Can Multipacks. Essentially, if you need to wrap high volumes of individual boxes or create secure bundles of items like Tissue Paper Bundles, Toy Bulk Packs, or Cookware Set Boxes, a web sealer is often the most efficient choice, ensuring items like Mobile Accessory Packs or Car Accessory Packs are securely grouped.

An L-Sealer with a Shrink Tunnel is renowned for its versatility and is an excellent choice for wrapping a diverse range of individual boxes or smaller multi-packs with precision and aesthetic appeal. It’s particularly popular for retail-ready consumer goods such as Soap Boxes, Cosmetic Boxes, Perfume Boxes, Gift Boxes, Chocolate Boxes, Candy Boxes, Dry Fruit Packs, and various Biscuit Packs like Namkeen, Kurkure, and Chips Packs. In the food sector, it perfectly handles Ready-to-Eat Food Trays, Cake Boxes, Cupcake Packs, Muffin Trays, and Cookie Boxes. For electronics and accessories, consider an L-sealer for Toy Boxes, Phone Accessories, Mobile Cases, Charger Packs, Earphone Packs, LED Bulb Boxes, Power Bank Packs, and Battery Packs. It’s also highly effective for stationery items like Pen Sets, Book Sets, Notebook Packs, Diary Packs, Magazine Bundles, and Calendar Packs. Pharmaceutical and health products, including Syringe Packs, Tablet Strip Boxes, Herbal Product Packs, Ayurvedic Medicine Boxes, and Tube Packs (e.g., ointment), also frequently utilize L-sealers for secure individual wrapping. Its ability to create two seals in one motion makes it efficient for packaging a wide variety of items from Jewelry Boxes to Electronic Gadget Boxes and even Hair Oil Bottles and Face Cream Boxes.

The fundamental difference lies in the level of operator intervention. A Semi-Automatic Box Shrink Wrapping Machine requires an operator to manually position each box into the film, after which the machine automatically performs the sealing (using either an L-seal or web seal mechanism) and transfers the product to the shrink tunnel. This offers a cost-effective balance, reducing manual effort while maintaining flexibility for varying Soap Boxes, Cosmetic Boxes, or smaller bundles of Biscuit Packs. In contrast, a Fully Automatic Box Shrink Wrapping Machine integrates seamlessly into a production line, with boxes (e.g., Water Bottle Bundles, Canned Food Packs, or large Electronic Gadget Boxes) automatically fed from an upstream conveyor. The machine independently handles film feeding, sealing, cutting, and conveying through the shrink tunnel, requiring minimal human oversight. This dramatically increases throughput and efficiency for high-volume operations, consistently packaging items like Soft Drink Bottle Multipacks, Pharmaceutical Bottle Trays, or large Appliance Boxes without manual loading, optimizing labor costs and ensuring consistent, professional results for Industrial Bearing Packs or Car Accessory Packs.

Investing in an Automatic Box Shrink Wrapping Machine significantly boosts your business’s bottom line through enhanced efficiency, cost savings, and improved product presentation. By automating the packaging of products like Juice Bottle Packs, Shampoo and Conditioner Sets, or Ready-to-Eat Food Trays, you drastically reduce labor costs and increase packaging speed (throughput). The tight, secure wrap offers superior product protection against dust, moisture, and tampering, which is vital for items such as Ayurvedic Product Combos, Mobile Accessory Packs, or high-value Electronic Gadget Boxes, thereby minimizing damages and returns. Furthermore, the professional finish of a shrink-wrapped product elevates your brand image, making items like Chocolate Gift Packs, Perfume Boxes, or Toy Boxes more appealing to consumers. Machines optimize film usage, leading to material cost savings. Whether you’re packaging Beer Bottle Packs, Dairy Product Gift Packs, or large Fan Boxes, the automation frees up staff for other critical tasks, leading to overall operational optimization and a stronger competitive edge in the market.

Founded in 1998 in Mumbai, India, AmarPack Machines Pvt. Ltd. is one of India’s leading manufacturers and exporters of premium packaging machines. Read More

GST No. 27AAZCA2345J1Z6

Get a quick quote from our experts. Fast response guaranteed!